Section 5 - Maintenance

90-899883179 OCTOBER 2007 Page 67

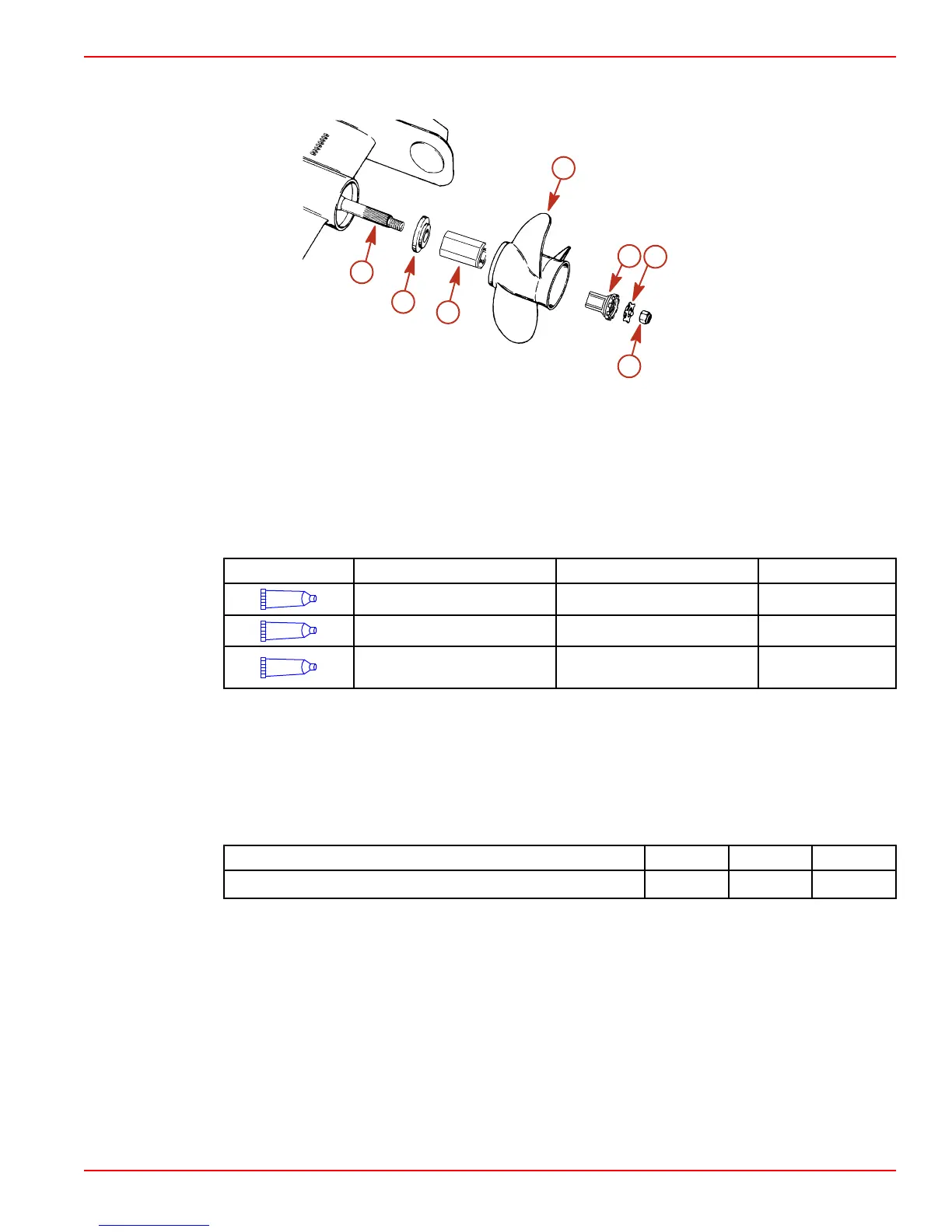

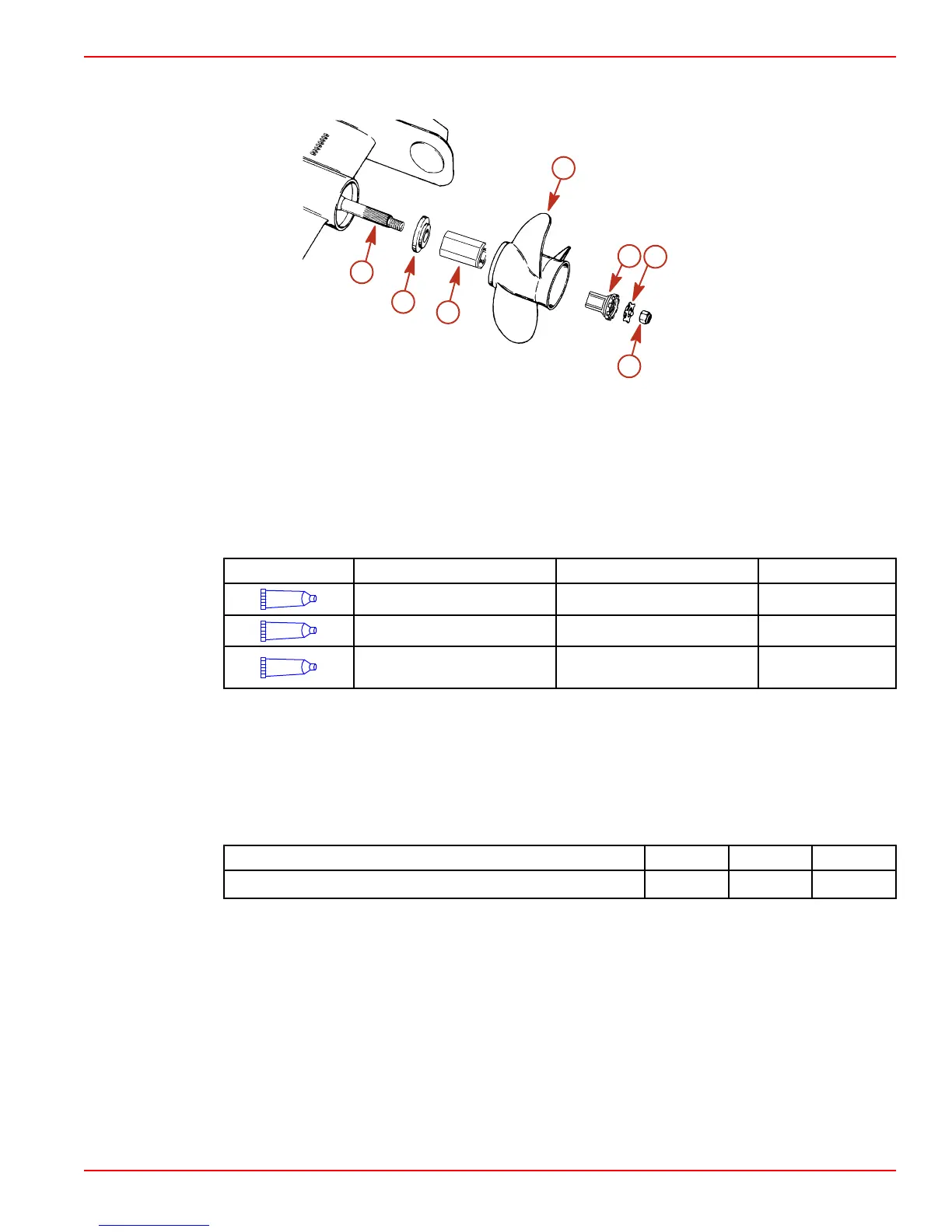

IMPORTANT: If reusing tab washer, carefully inspect tabs for cracks or other damage.

Replace tab washer if condition is questionable.

a

b

c

d

e

g

6215

f

a - Propeller shaft

b - Thrust hub

c - Flo‑Torq II drive hub

d - Propeller

e - Drive sleeve

f - Locking tab washer

g - Propeller nut

1. Slide thrust hub onto propeller shaft, with stepped side toward propeller hub.

2. Apply a liberal coat of one of the following lubricants to the propeller shaft.

Tube Ref No. Description Where Used Part No.

34

Special Lubricant 101 Propeller shaft 92-802865Q02

94

Anti-Corrosion Grease Propeller shaft 92-802867Q 1

95

2-4-C Marine Lubricant with

Teflon

Propeller shaft 92-802859A1

3. Install Flo‑Torq II Drive Hub into propeller.

NOTE: The drive sleeve is tapered and will slide fully into the propeller as the nut is

tightened and properly torqued.

4. Align splines and place propeller on propeller shaft.

5. Install drive sleeve and locking tab washer.

6. Install and torque the propeller nut.

Description Nm lb. in. lb. ft.

Propeller nut

1.

75 55

7. Bend three tabs on the tab washer down into the grooves in spline washer. After the

first use, bend the three tabs straight and retorque the propeller nut. Bend tabs back

down into spline washer. Check propeller at least after 20 hours of operation. Do not

operate with loose propeller.

1. The propeller torque stated is a minimum torque value.

Loading...

Loading...