INSTRUCTION MANUAL ME-104 3

1. GENERAL MACHINE DESCRIPTION

The machine ME 104 wraps automatically every kind of mattresses (springs, latex, foam,…)

from polyethylene rolls. The machine provides advance of the mattress trough the film and

adjusts itself to the appropriate measures. The finished mattress is ready to be stocked

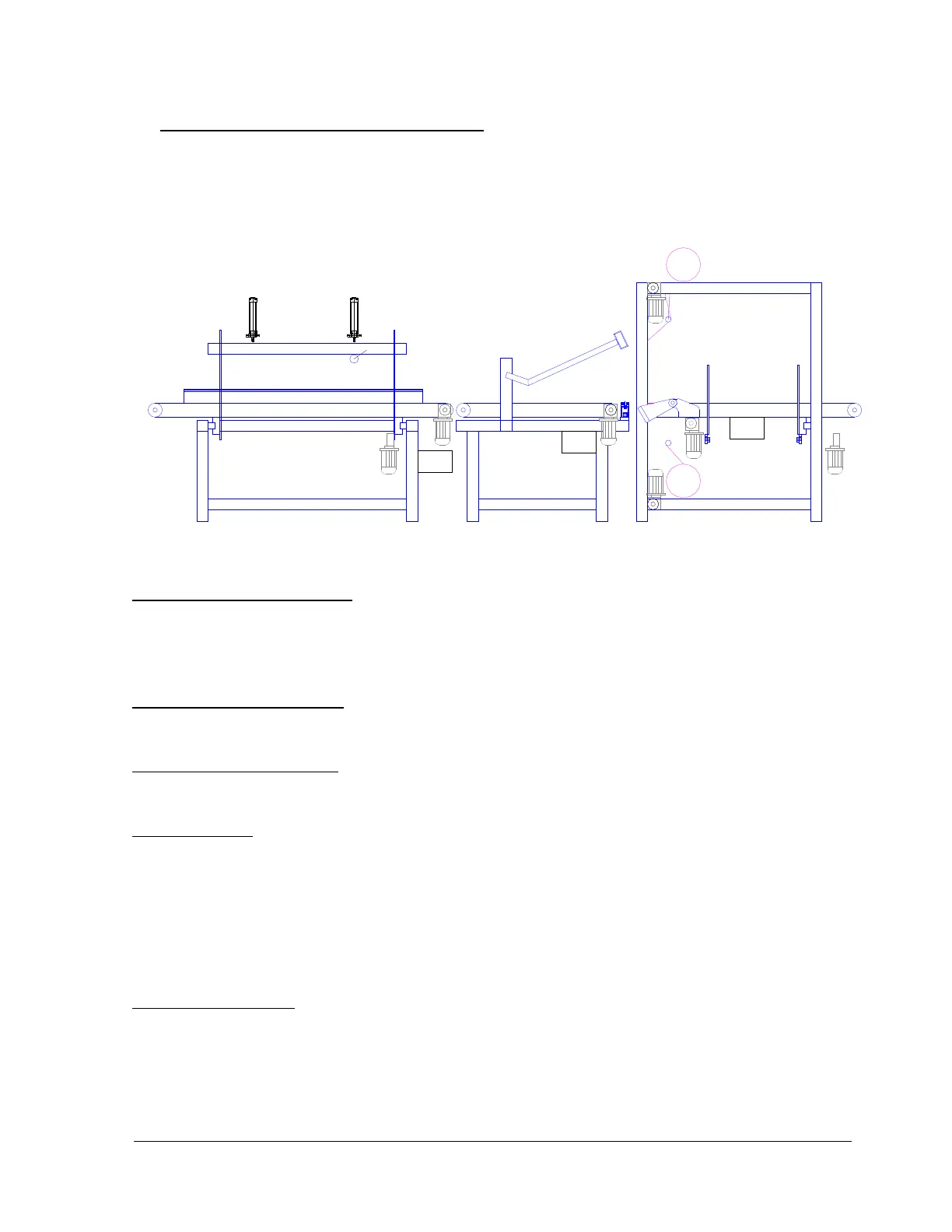

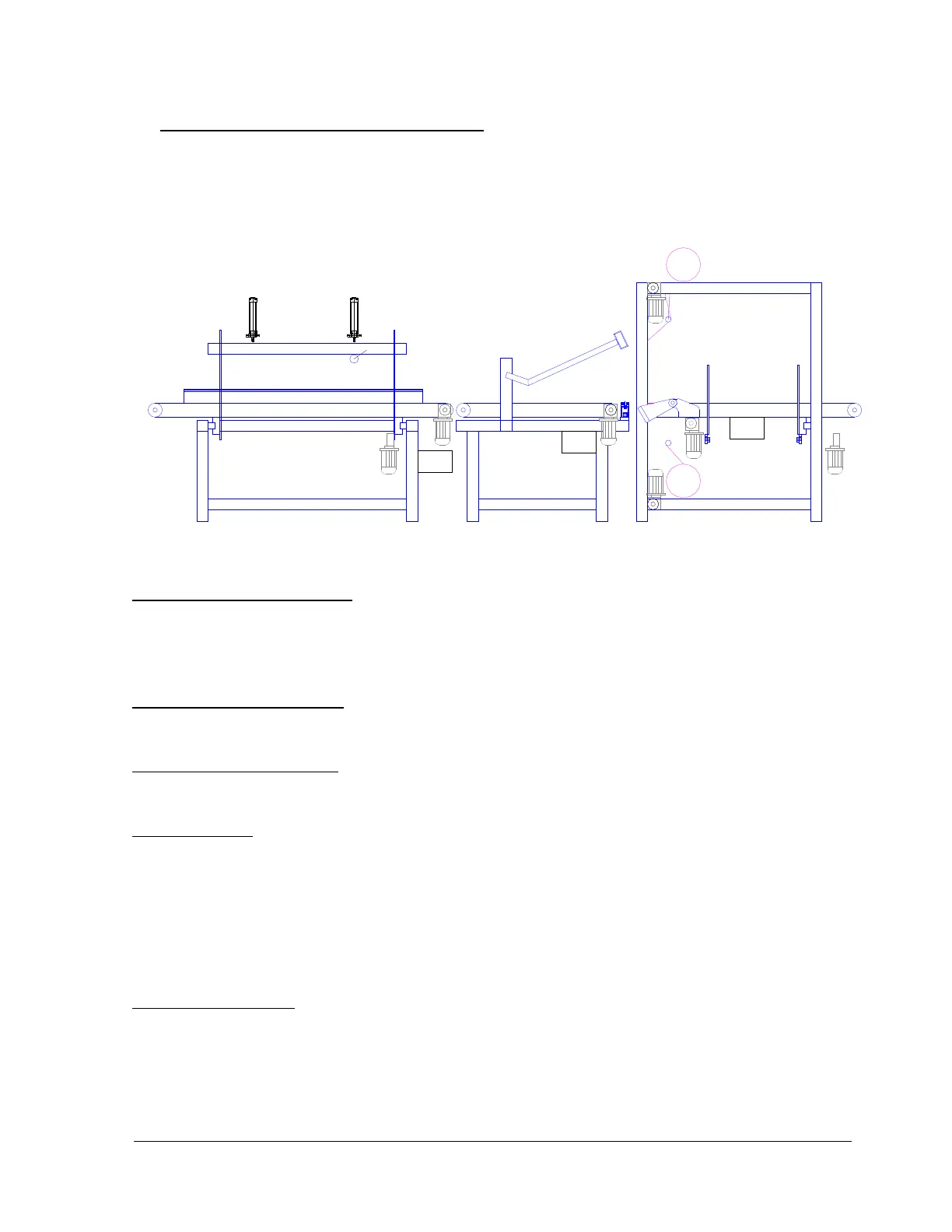

The machine is compound by the following elements:

EM2

S3

BOX 2

S4

M3

M6

BOX 3

M1

FC1

M7

S2

M4

M5

S7

BOX 1

S1

FC0

M2

S5

S6

MODULE 1MODULE 3 MODULE 2

Module nº1: Mattress In-feed: receive the mattress, put it on position for wrapping and measures

the length for adjust the corresponding sealing bars distance. The machine detects a new mattress

automatically and starts moving the in-feed conveyor. This module contains the upper and lower

rolls of film. For sincronice with in-feed lines, (Y15 output) is ON when the machine is ready

Module nº2: middle sealing: receive the enfold mattress from the previous module, seals all along

and separates the bag from the rolls, cutting it by blade

Module nº3: lateral sealing: receive the wrapped mattress from the previous module, seals both

sides, cut the waste of film by blade and give the mattress away.

Control cabinet: keeps the electrical and electronic components that provide the control of the

machine. A screen allows the man-machine dialogue, input parameters and show error messages.

In order to reduce the electrical peaks, the machine avoids the activation of both welding bars

at the same time. This way, a half-wrap mattress waits for the sealing of the previous.

The machine complies with safety requirements of CE as expressed on last chapter

TECHNICAL DATA

AERIAL NOISE: 70 dB(A)

WEIGHT MODULE 1: 1.400 Kg

WEIGHT MODULE 2: 800 Kg

WEIGHT MODULE 1: 1.600 Kg

Loading...

Loading...