15

Meritor Differential Carrier 18X

2 Maintenance

Fig. 2.3

Fig. 2.2

Bearing

Tool

MST4904

CAUTION:

Only original Meritor spare parts should be used.

Use of non-original parts could seriously affect differential

unit performance. Use of non-recommended lubricants will

adversely affect performance and service life.

WARNING:

Waste oil disposal must be carried out in conformity with the

legislation in force.

CAUTION:

Differential carrier removal and handling should be

performed using the specified lifting and carrying

equipment.

CAUTION:

During dismantling/reassembly operations always engage

differential lock to ensure alignment of the splined sections

and prevent shift fork bending and spline damage.

Finally, ensure that:

• There are no leakages from air lines.

• Lubricating oil meets manufacturer’s specifications.

• Differential lock cab warning lamp functions correctly.

Ring Gear & Pinion Adjustment

If a new ring gear and drive pinion are to be installed, the correct

thickness of shim pack required between the inner bearing cup

and the carrier must be determined.

When the correct shims pack has been identified, the bearing

preload on the drive pinion must be adjusted. The preload is

controlled by the thickness of the spacer between the inner and

outer cones of the pinion bearings.

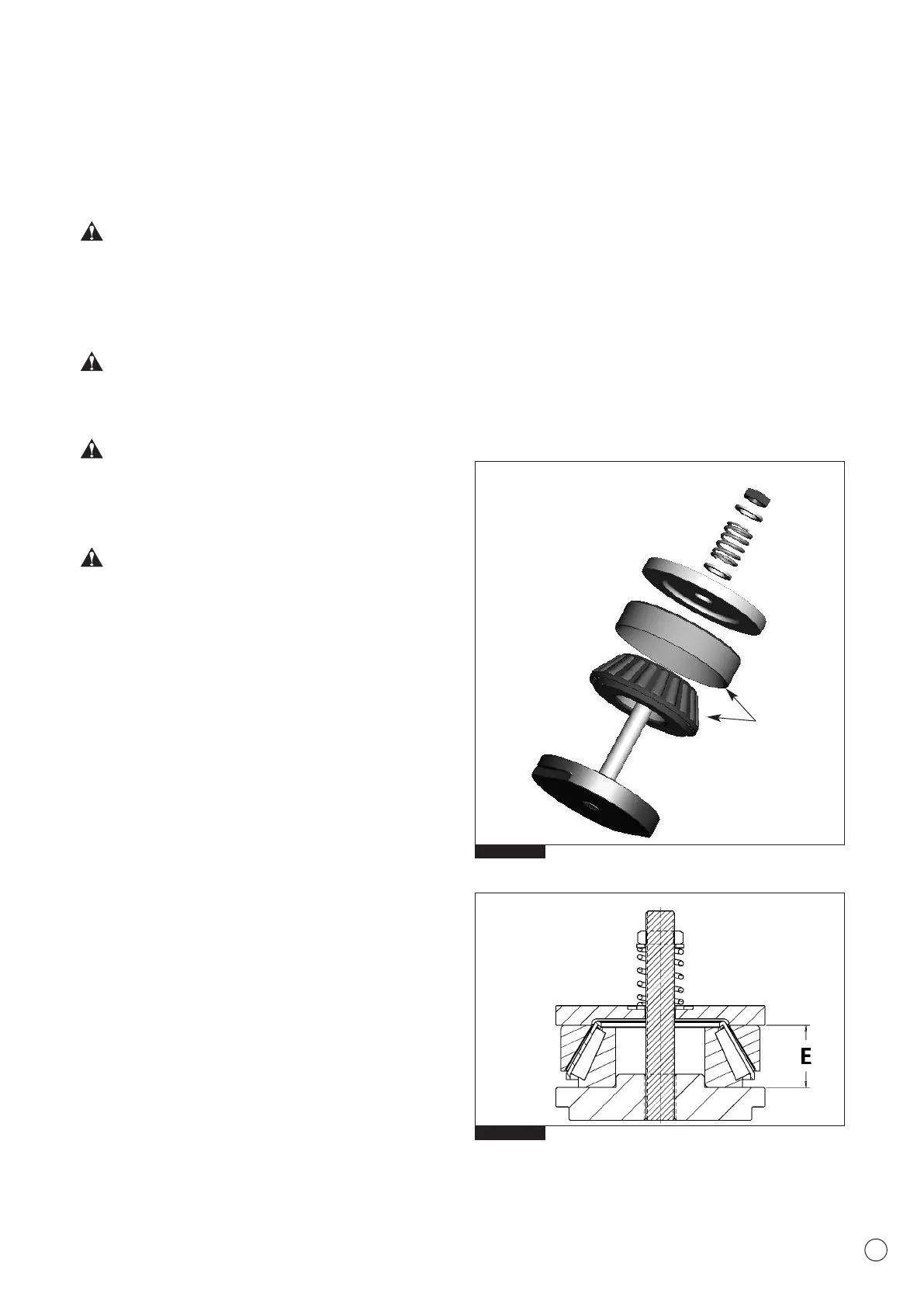

Determining the Pinion Inner Bearing Dimension

Before assembling the carrier, measure the complete inner pinion

bearing assembly compressed into a suitable service tool

MST4904, as detailed below. Place the complete bearing into a

suitable service tool and rotate it while tightening the tool

(Fig 2.2).

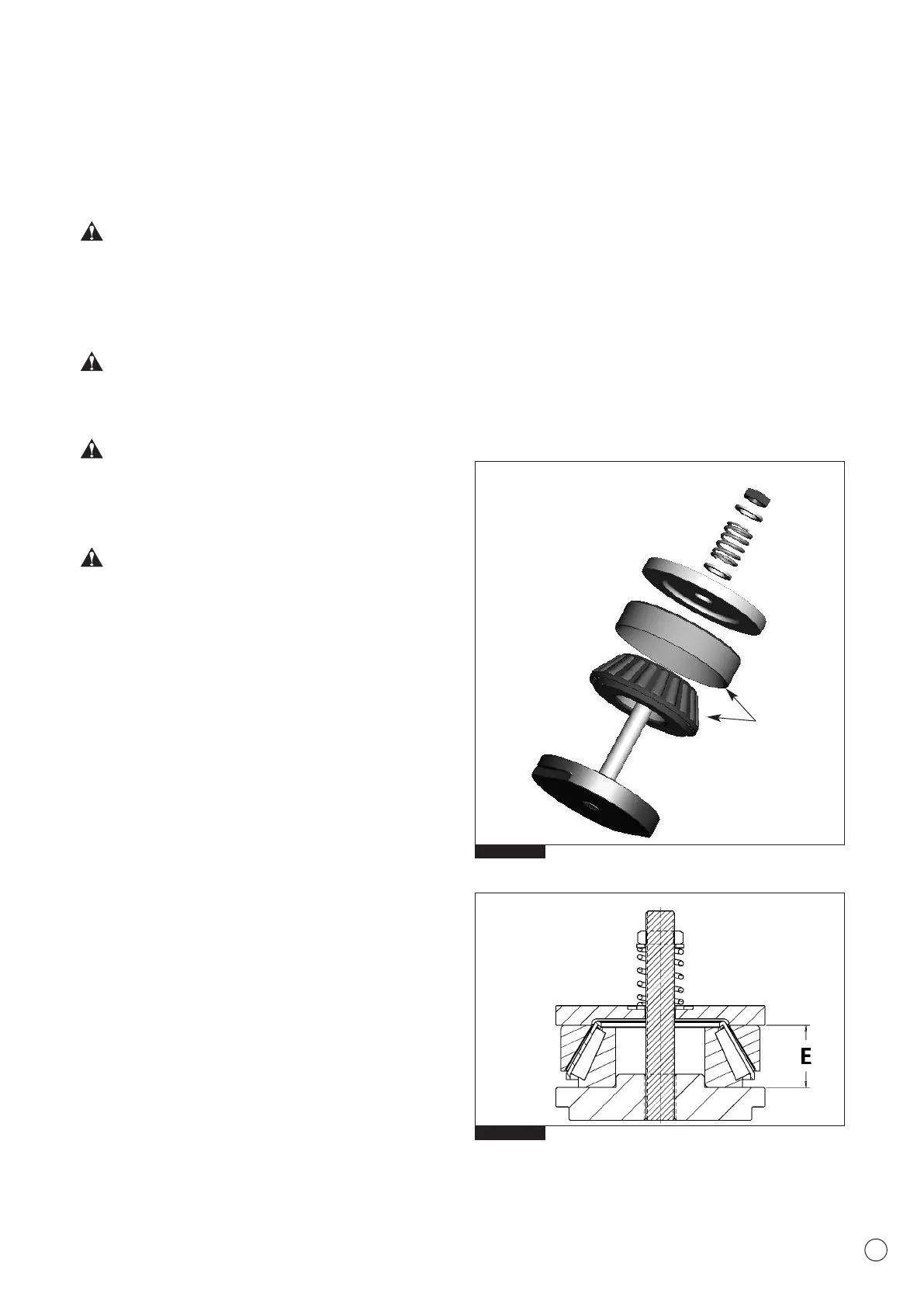

Tighten the tool until the bearing is completely seated (Fig 2.3).

If the tool is not available press the bearing with 1.000 N or 100 kg

load and take measurement in three points - about 120 degrees.

Measure the internal distance between the service tool plates at

three equally spaced points to determine the total width of the

bearing E (Fig 2.3) (e.g. 58.10). Record dimension E as it is

required for Shim Pack calculation below.”

Loading...

Loading...