13

6 Electrical connection

7 Setting the hot-spot gradient

screw and remove the pressure ring. Push the pressure screw

and gasket over the temperature detector (9.5 mm diame-

ter) and the capillary tube. Thread the temperature detector

40 – 50 cm through the small cable gland connection until

it reaches the stop (at a depth of approx. 215 mm) in the

transformer temperature sensor sleeve of the ZT-F2.1 trans-

former temperature transmitter. Pull the capillary tube until

it is straight and then install it. Then tighten the cable gland

connection until it is liquid-tight.

Push the replacement sensor (Appendix/Fig. 7) into the tem-

perature sensor sleeve of the ZT-F2.1 transformer temperature

transmitter until it reaches the stop (at a depth of approx. 215

mm). Seal off the unused cable gland connection as tightly as

possible.

6 Electrical connection

6.1 Connecting the current transformer

Connect the current transformer to terminals 1 + 2 of the ZT-

F2.1 transformer temperature transmitter. The rated secondary

current should be 1.5 to 2 A. Use a ballast transformer accor-

ding the desired hot-spot gradient for other currents.

6.2 Pt100 measuring resistor

The ZT-F2.1 is equipped with a Pt100 measuring resistor con-

forming to IEC 751. The indicator instrument that is used can

be designed as 2, 3 or 4-conductor.

Length of the connection lines

The length of the connection lines depends on the specifica-

tions of the measuring transducer or indicator device to be

connected (e.g., one Pt-MU 100 Ω per line). In general, a line

length of 50 m should not be exceeded if the 3-conductor

technique is used. With the 3 or 4-conductor technique, make

sure that the individual leads are identical (i.e., same length,

same cross section). Otherwise differences may occur due to

incorrect compensation of the line resistors.

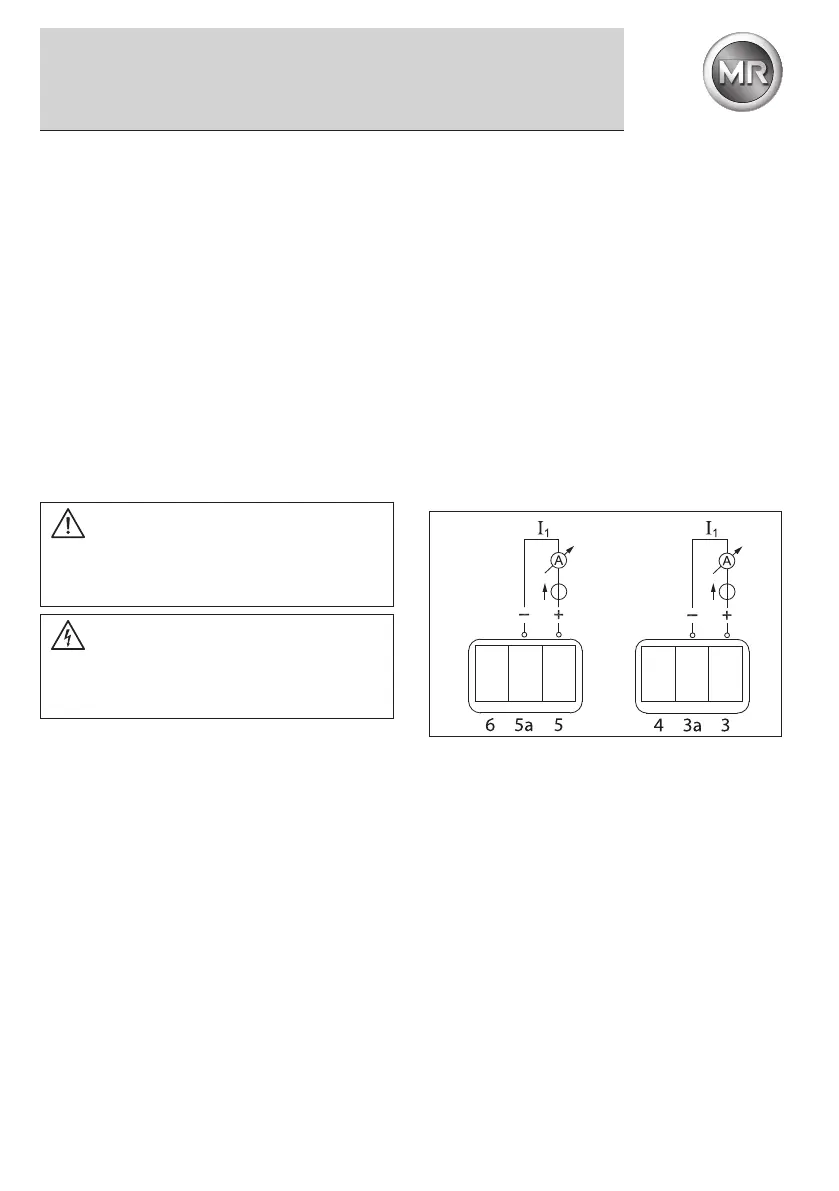

3-conductor technique

A 3-conductor indicator instrument (2 measuring lines and

1 compensation line) is to be used. The sensor lines are con-

nected to terminals 3 and 4 and the equalizing line to terminal

3a (see figure 3, item 2).

2-conductor technique

When a 2-conductor indicator instrument is used (2 measuring

lines), one measuring line is connected to terminal 3 and the

other measuring line is connected to terminal 4 (see figure 3,

item 2).

4-conductor technique

When a 4-conductor indicator instrument is used (2 measuring

lines and 2 compensation lines), the same connections are used

as for the 3-conductor technique. The second compensation

line must be connected to terminal 4

(see figure 3, item 2).

Option

When the configuration of the ZT-F2.1 with two Pt100 measu-

ring resistors is used, an additional indicator instrument can be

connected to terminals 6, 5a and 5 (see figure 3, item 3).

6.3 Option: Transducer 4...20mA

The ZT-F2.1 can be delivered with the 4...20 mA analog output

instead of the Pt100 measuring resistor. The 2-conductor

connection technique (R/L max. 750Ω at 24 V DC) is used with

connection to terminals 3a and 3 (see figure 2 and figure 3,

item 2).

Current loop I1 as passive analog output:

The device acts as a controlled resistance which, at a supply

voltage between 10-30 V DC, controls the current flow bet-

ween 4-20 mA as the measured temperature to be shown

Option

Optional configuration of the ZT-F2.1 with two analog outputs

or one analog output and one measuring resistor is also possi-

ble. Connection is then made to terminals 5a and 5 (see figure

2 and figure 3, item 3).

7 Setting the hot-spot gradient

7.1 Setting for 2 A CT nominal current

The hot-spot gradient (at nominal load) is set via the two DIP

switches S1 and S2 located on the ZT.F2.1 board. Determine

WARNING

Hazardous electrical voltages!

All connecting wiring must be free of voltage before opening

the device.

CAUTION

Electrical connections may only be carried out by qualified,

skilled personnel trained in the applicable safety regulati-

ons of the relevant country.

Fig. 2

min. 10 V DC

to max. 30 V DC

min. 10 V DC

to max. 30 V DC

Loading...

Loading...