14 | P a g e M o d e l V B 2 8 0

TRACTOR TOWING SIZE REQUIREMENTS

The spreader does not have brakes, towing the spreader must be done safely. The ASAE (American Society of

Agricultural Engineers) specifies that the towing vehicle should weigh at least 2/3 as much as the loaded

implement to be reasonably safe towing at speeds up to 20 mph. This (20 mph) is also the maximum

recommended towing speed for the spreader.

The loaded weight of your spreader will naturally vary with the moisture of the manure and you must consider that

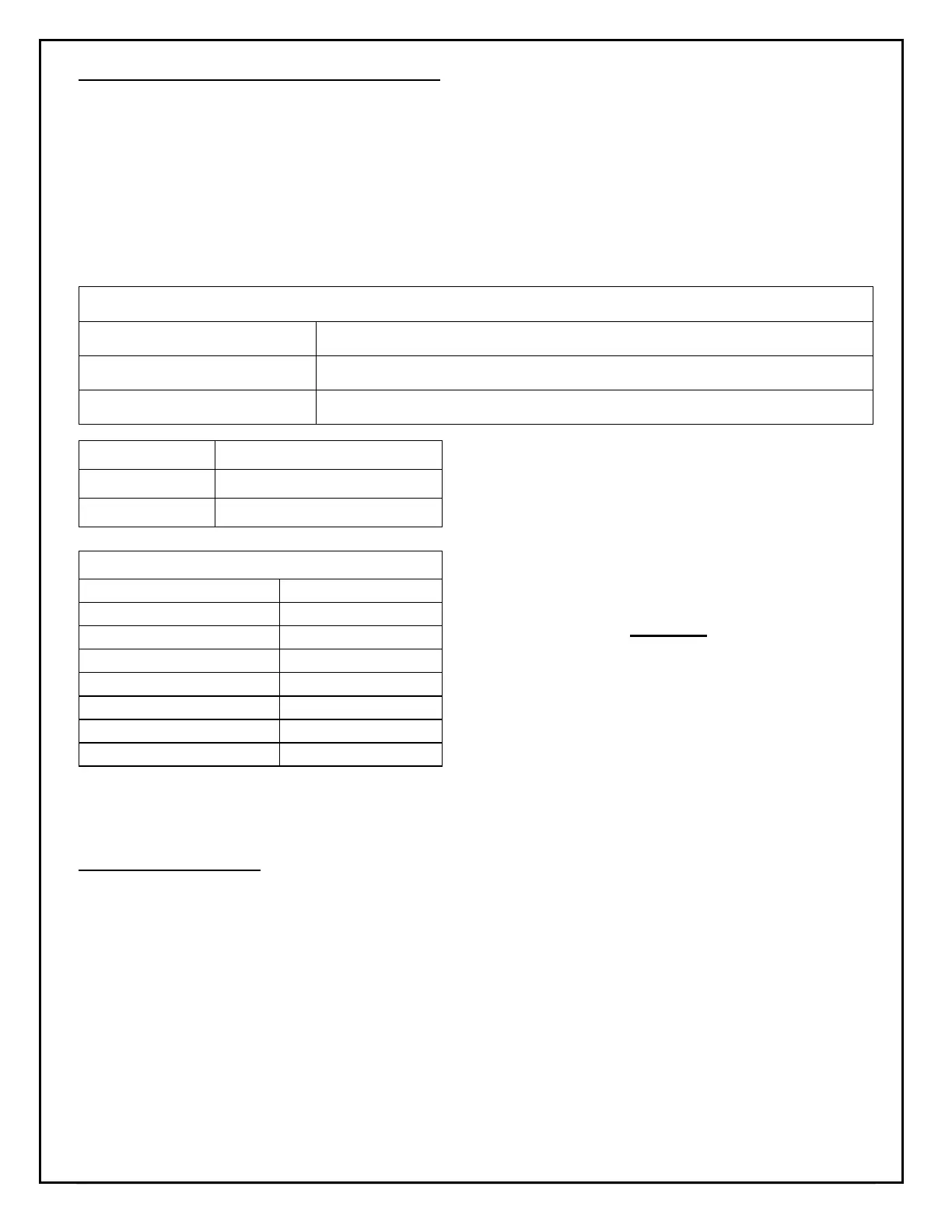

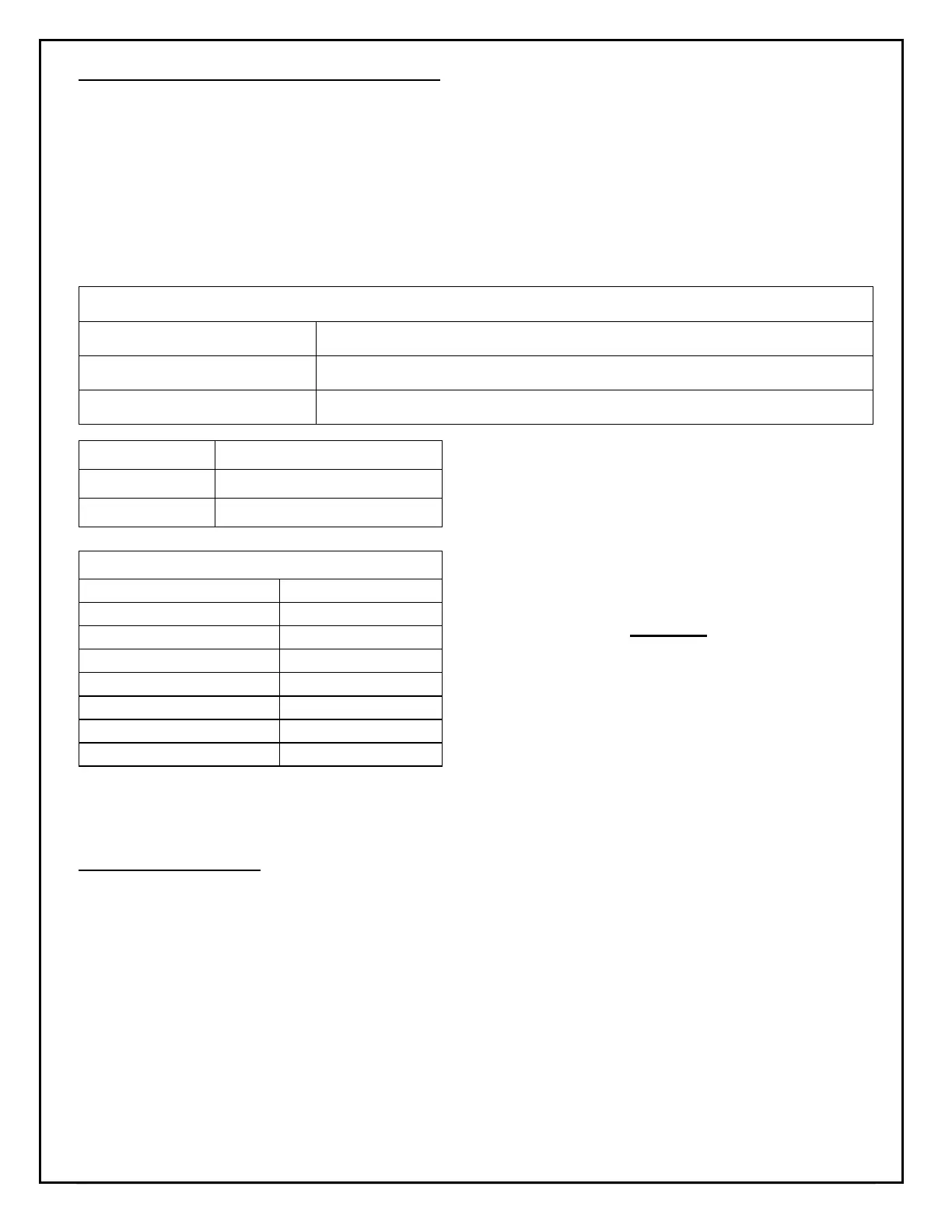

for your conditions. The loaded weight as specified by the spreader manufacturer is as follows:

Use the following charts for calculating spreader gross weight and minimum tractor weight:

HYDRAULIC SYSTEM

There are two hydraulic circuits on the spreader:

1. One circuit powers the hydraulic end gate.

2. The second circuit powers the hydraulic apron

drive. A check valve is installed in this circuit to

prevent

operating the apron in reverse. Also, the hydraulic motor has a built-in relief valve that is preset.

Therefore, the tractor requires two sets of remote ports with a minimum recommended flow of 15 GPM.

The hydraulic system is rated for 3000 PSI. Tractor relief settings should not exceed 2500 PSI!

The spreader ships from the factory setup for closed center systems.

NOTICE!

HEAPED LOADS HAVE SIGNIFICANTLY

HIGHER CAPACITIES RESULTING IN

INCREASED

WEIGHT AND HIGHER CENTER

OF GRAVITY,

REQUIRING EXTRA

PRECAUTION DURING OPERATION.

EXAMPLE

A heaped load of pen packed manure:

Load Weight = 470 x 35 = 16,450 LBS

Gross Weight = 10,500 + 16,450 = 26,950 LBS

Tractor Weight = 26,950 x (2/3) = 17,967 LBS

Loading...

Loading...