14 ACDC200LCD

Earth Clamp Connection

Connect the earth clamp cable to the positive terminal on the front of the machine,

and the clamp to the work piece. Clear any dirt, rust, scale, oil or paint on the earth

clamp. Make certain you have a good solid ground connection. Make sure the earth

clamp touches the metal.

Gas Installation

WARNING

!!

Shielding gas cylinders and high pressure cylinders can explode

if damaged, so treat them carefully.

• Never expose cylinders to high heat, sparks, open ames,

mechanical shocks or arcs.

• Do not touch cylinder with TIG torch.

• Do not weld on the cylinder.

• Always secure cylinder upright to a cart or stationary object.

• Keep cylinders away from welding or electrical circuits.

• Use the proper regulators, gas hose and ttings for

the specic application.

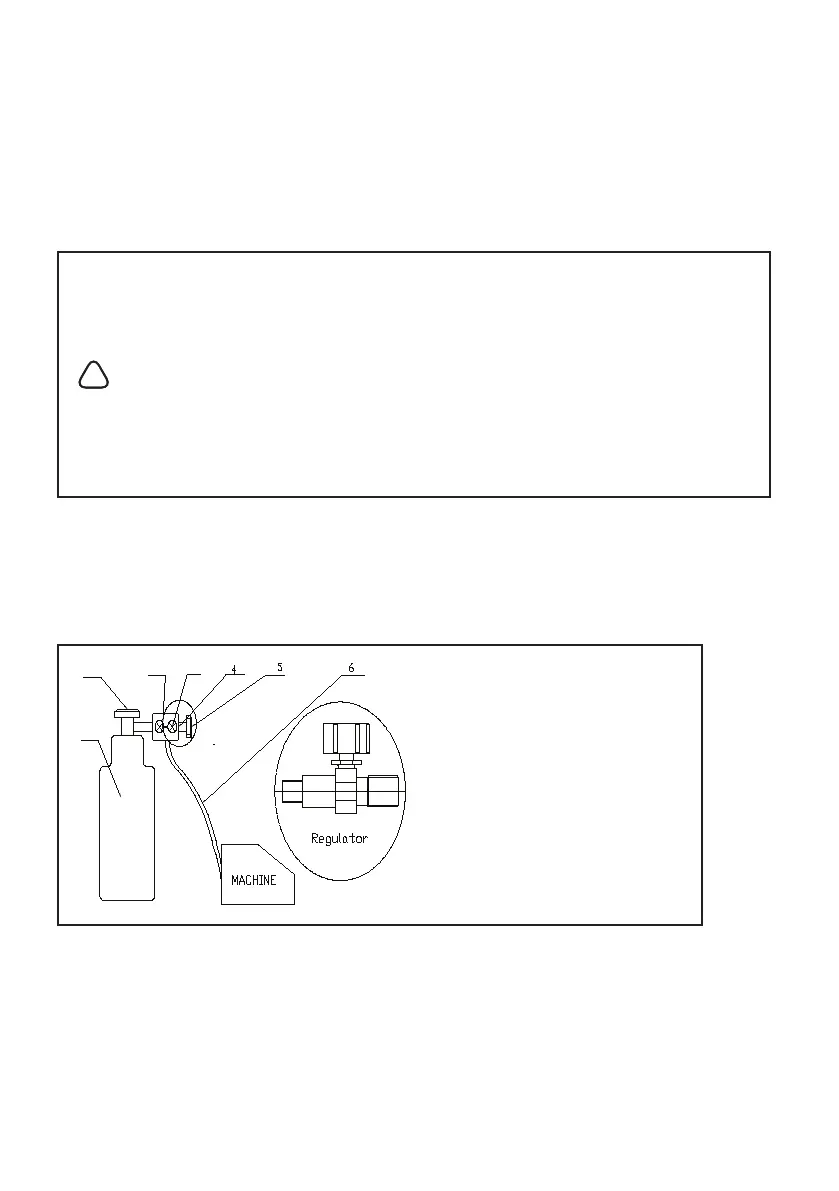

The gas hose

The gas hose, regulator and gas cylinder connection is shown below. Attach one end

of the gas hose to the gas solenoid valve (gas inlet) located on the back panel of the

welder. Attach the other end to the gas regulator which is attached to the shielding

gas cylinder. See illustration below:

1 Cylinder valve: Controls GAS

CYLINDER gas ow.

2 Cylinder pressure gauge

3 Gas ow gauge, see set up charts

for recommended settings

4 Regulator

5 Adjustment knob controls gas

pressure to the welder.

6 Gas hose

7 Gas cylinder

NOTE: Slowly open the cylinder valve by turning it counter-clockwise until the

cylinder pressure gauge registers on the rst gauge of the regulator. Turn the

adjustment knob clockwise (right) slowly to increase gas ow (check the set up

guide on the machine for guidelines on gas ow. To reduce the gas ow, turn the

adjustment counter-clockwise (left). The gas valve is located on the back panel of the

welder and activated by the trigger. Gas ow should be heard when the trigger is

activated. Avoid unnecessary gas loss by closing the tank valve when

nished welding.

Loading...

Loading...