28 ACDC200LCD

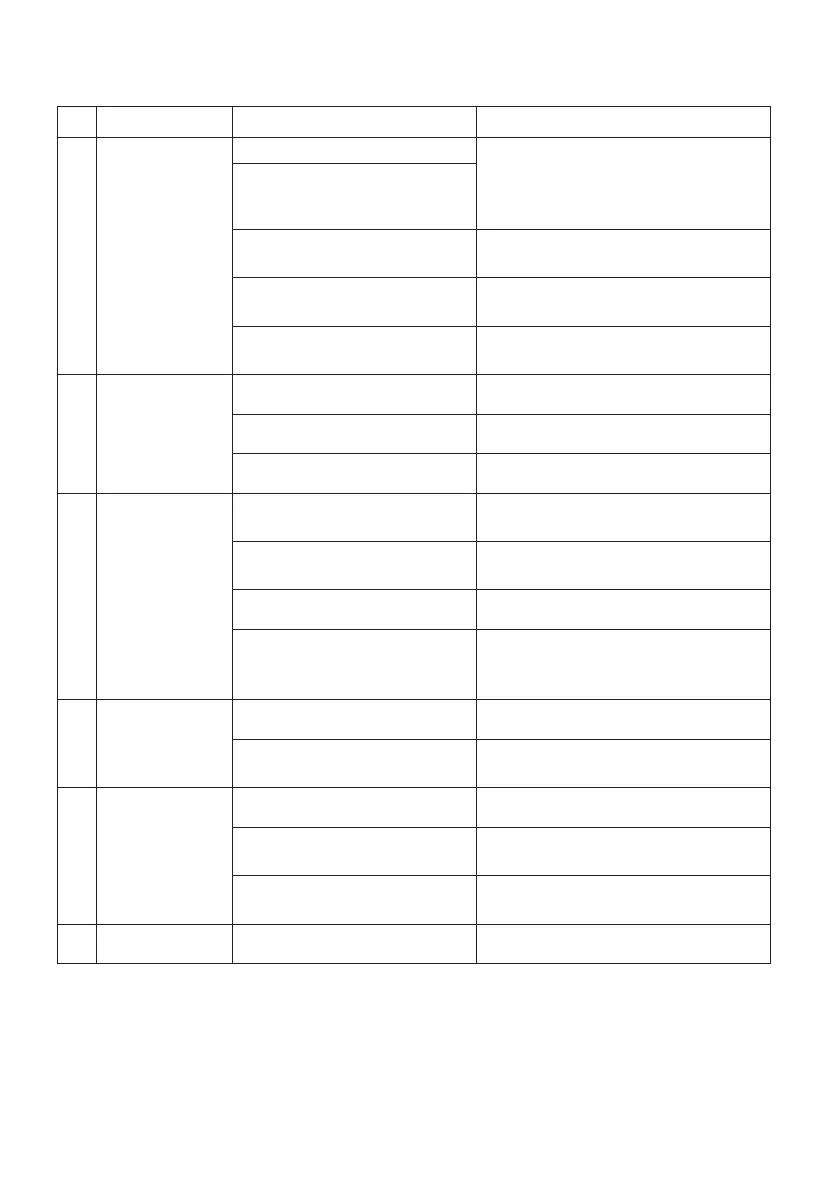

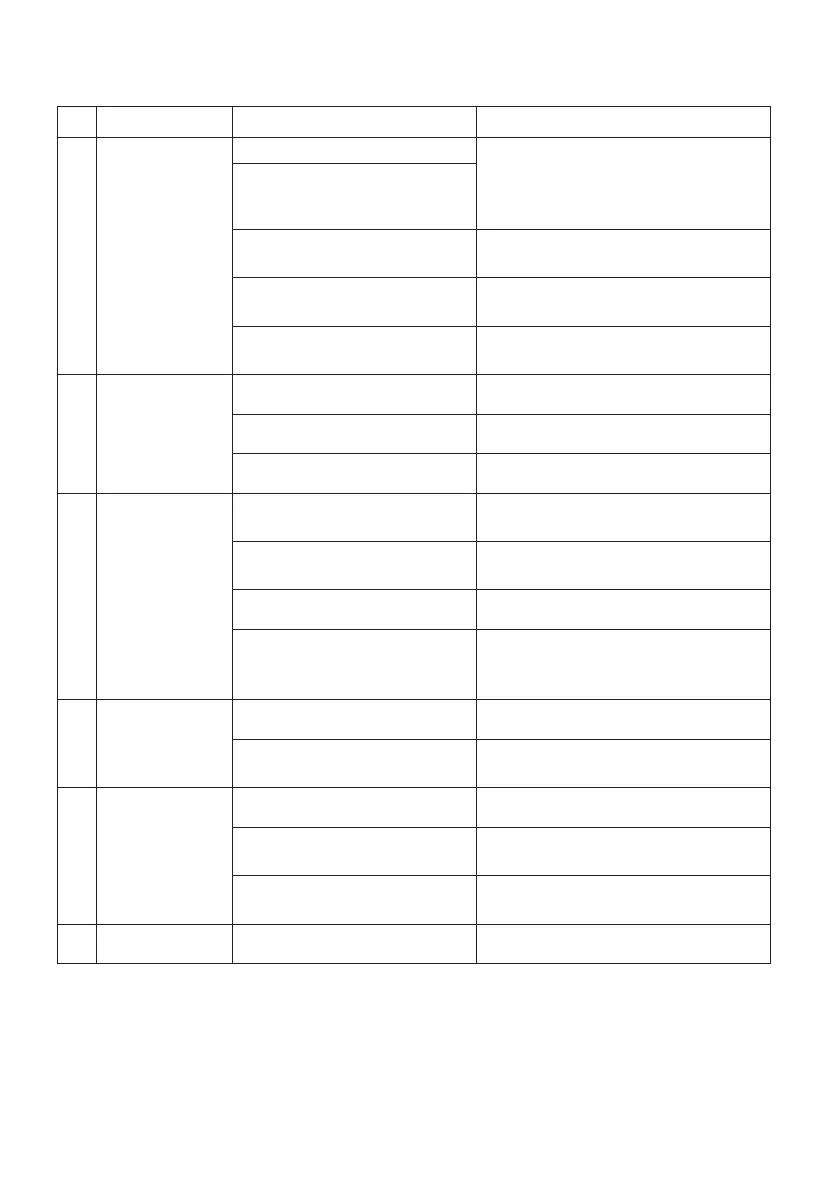

TROUBLE SHOOTING CHART

No Breakdown Analysis Solutions

1

Yellow

Indicator is on

Voltage is too high (≥15%) Switch o power source; Check

the main supply; Restart welder

when power recovers to normal

state.

Voltage is too low (≤15%)

Bad power ventilation lead

to over-heat protection

Improve the ventilation

condition.

Circumstance temperature

is too high.

It will automatically recover when

the temperature has lowered.

Using over the rated

duty-cycle.

It will automatically recover when

the temperature has lowered.

2

Cooling Fan

not working

or turning

very slowly

Switch broken Replace the switch

Fan broken Replace or repair the fan

Wire broken or falling o Check the connection

3

Arc is not

stable and

splash is large

Too large contact tip makes

the current unsteady

Change the proper contact

tip or roller

Too thin power cable makes

the power asceticism

Change the power cable

Too low input voltage Enhance the input voltage

Wire feeding resistance is

too large

Clean or replace the liner and the

torch cable had better in the line

direction.

4 Not arcing

Earth cable break Connect earth cable

Work piece has grease or

rust on it.

Clean grease or rust

5

No shielded

gas

Torch is not connected well Connect the torch again

Gas pipe is pressed or

blocked up

Check gas system

Gas system

rubber pipe break

Connect gas system

and bind rmly

6 Other Please contact Total Tools

Loading...

Loading...