16 ACDC200LCD

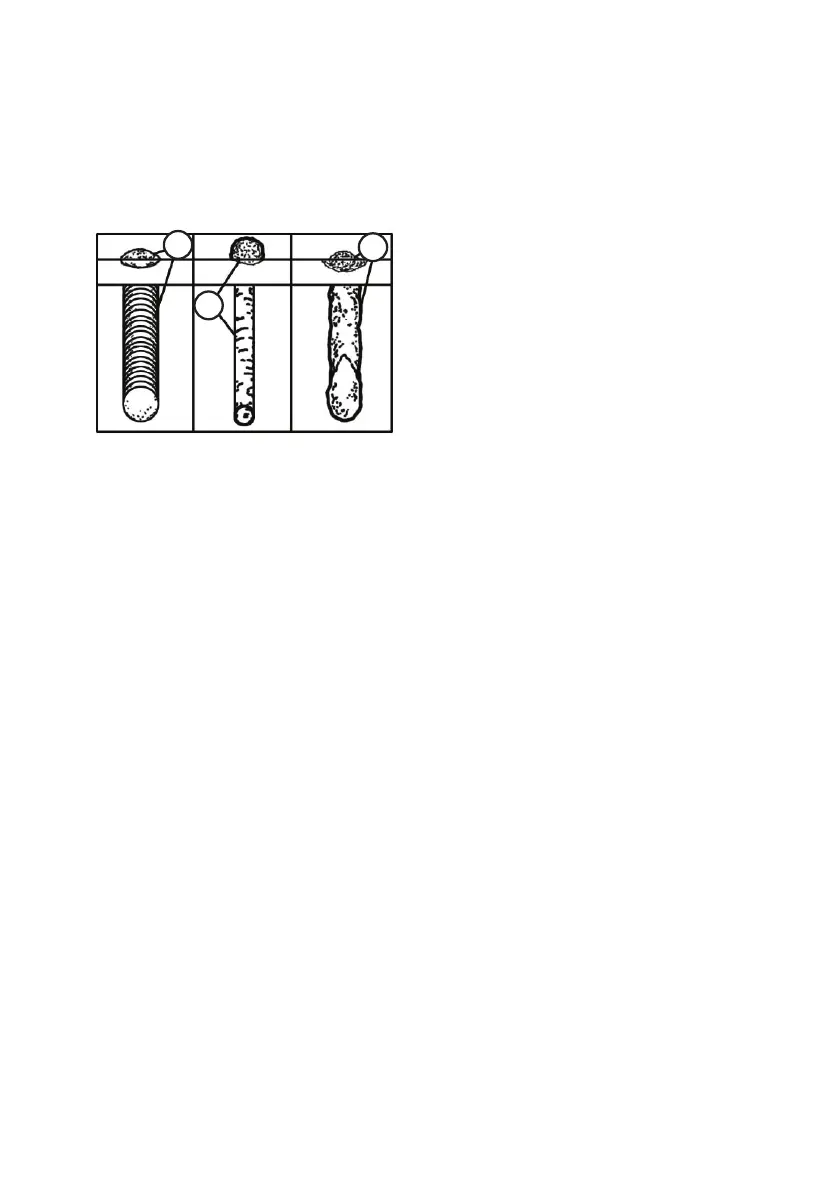

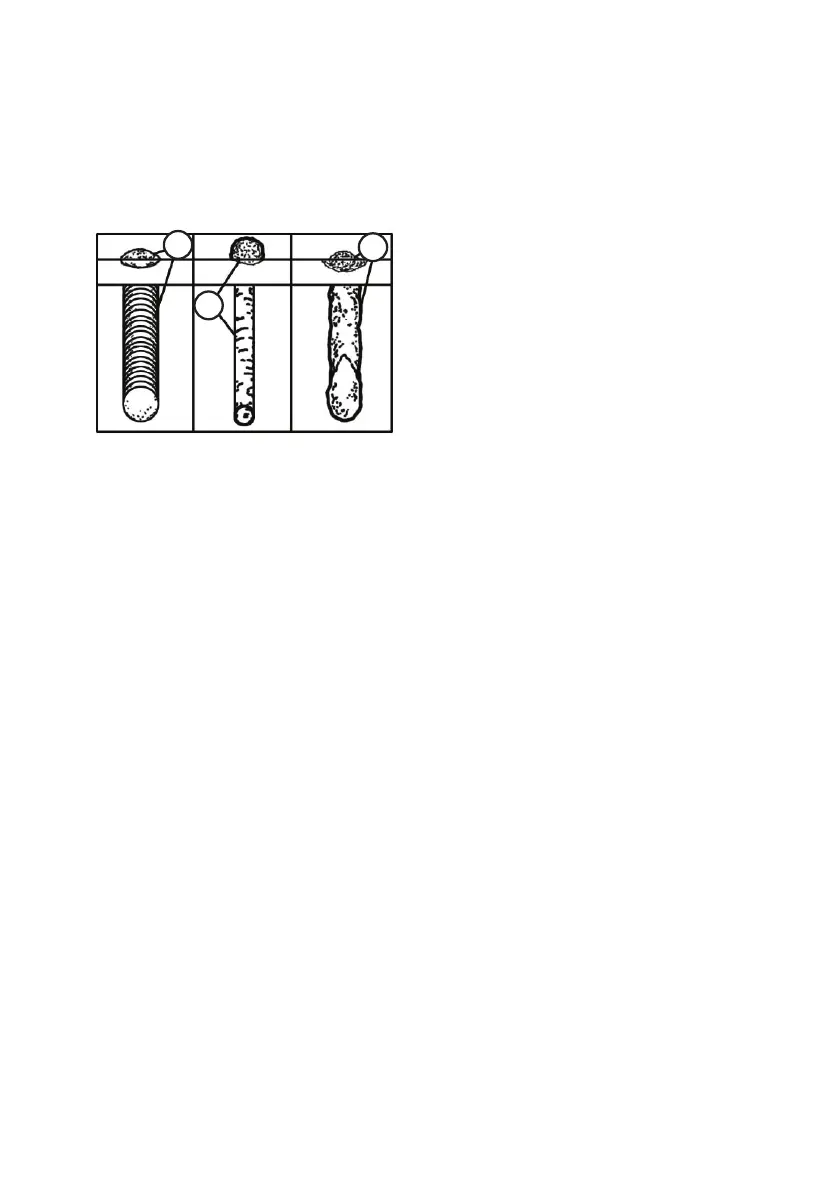

c) The bead will be at and porous

d) Rod may be freeze or stick to work piece

Note: Rate of travel over the work also aects the weld. To ensure proper penetration

and enough deposit of rod, the arc must be moved slowly and evenly along the weld

seam.

1

2

3

Electrode holder connection

1. Attach the Twist-lock electrode holder to the +ve terminal on the ACDC200LCD

2. Open the electrode holder by turning the head and handle in the opposite

directions until the head clamp opens.

3. Place the exposed end of the electrode into the lead clamp and hold in place.

4. Turn the handle to close the head clamp.

Setting the amperage control

The welder has an innite output current control.

There is no golden rule that determines the exact amperage required for every

situation. It is best to practice your welds on scrap metal which matches the metals

you intend to work with to determine correct setting for your job. The electrode type

and the thickness of the work piece metal determine the amount of heat needed in

the welding process. Heavier and thicker metals require more voltage (amperage),

whereas lighter and thinner metals require less voltage (amperage).

Electrode/Amperage Guide

2.5mm diameter E6013 Electrodes – 60 to 100amps

3.2mm diameter E6013 Electrodes – 80 to 150amps

Loading...

Loading...