19OPERATING MANUAL

The HORIZONTAL POSITIONS are performed very much the same as the at weld except

that the angle is dierent such that the electrode, and therefore the arc force, is directed

more toward the metal above the weld joint. This more direct angle helps prevent the

weld puddle from running downward while still allowing slow enough travel speed to

achieve good penetration. A good starting point for your electrode angle is about 30

degrees DOWN from being perpendicular to the work piece.

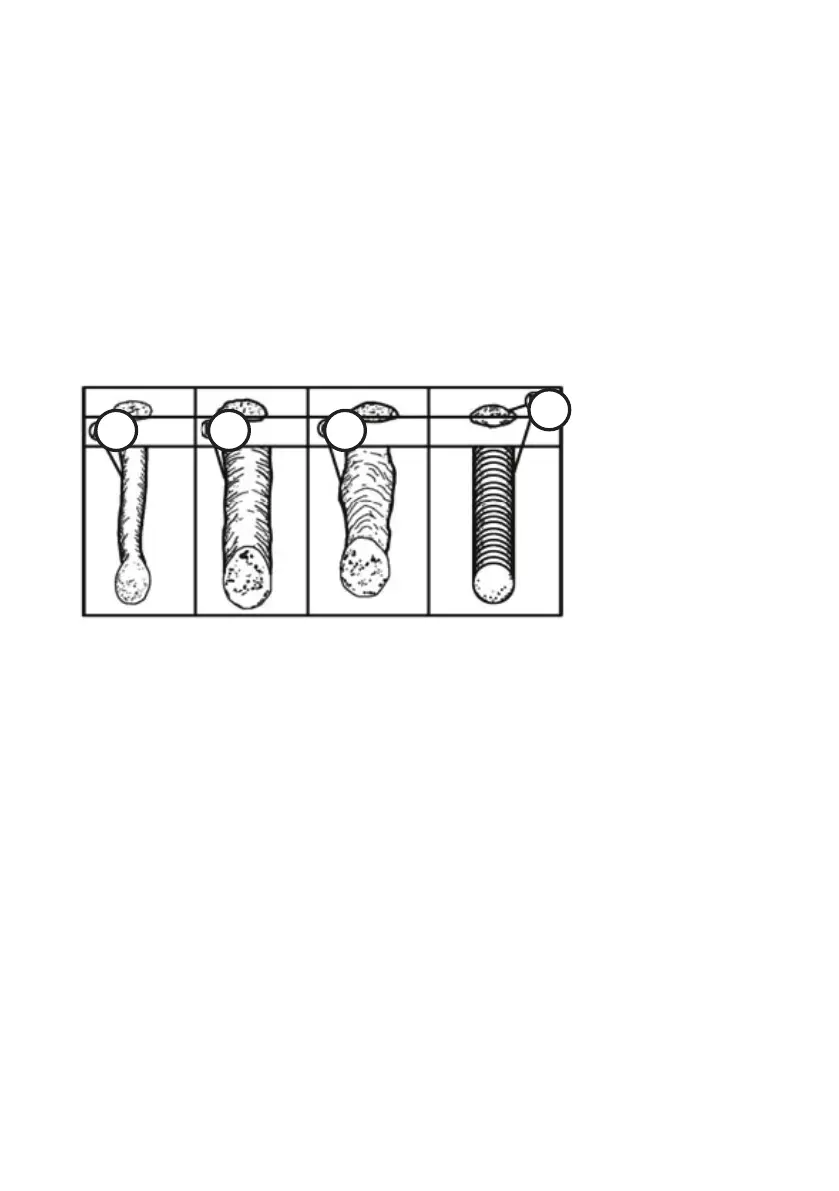

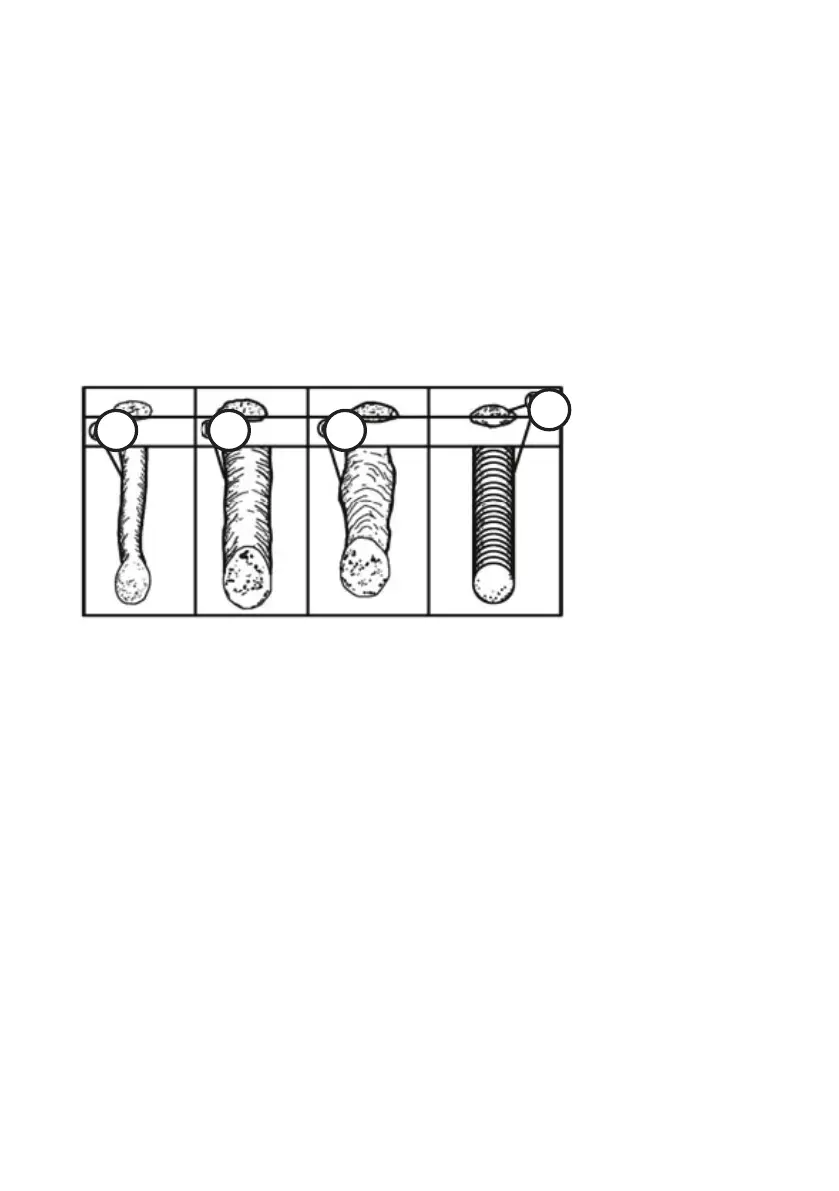

How to judge a good weld bead

When the trick of establishing and holding an arc has been perfected, the next step is

learning how to run a good bead. The rst attempts in practice will probably fall short

of acceptable weld beads. Too long of an arc will be held or the travel speed will vary

from slow to fast (see following):

1 2 3

4

1. Weld speed is too fast.

2. Weld speed is too slow.

3. Arc is too long.

4. Ideal weld.

A solid weld bead requires that the electrode be moved slowly and steadily along

the weld seam. Moving the electrode rapidly or erratically will prevent proper fusion

or create a lumpy, uneven bead. To prevent ELECTRIC SHOCK, do not perform any

welding while standing, kneeling, or lying directly on the grounded work.

How to nish the bead

As the coating on the outside of the electrode burns o, it forms an envelope of

protective gasses around the weld. This prevents air from reaching the molten metal

and creating an undesirable chemical reaction. The burning coating, however, forms

slag. The slag formation appears as an accumulation of dirty metal scale on the

nished weld. Slag should be removed by striking the weld with a chipping hammer.

Loading...

Loading...