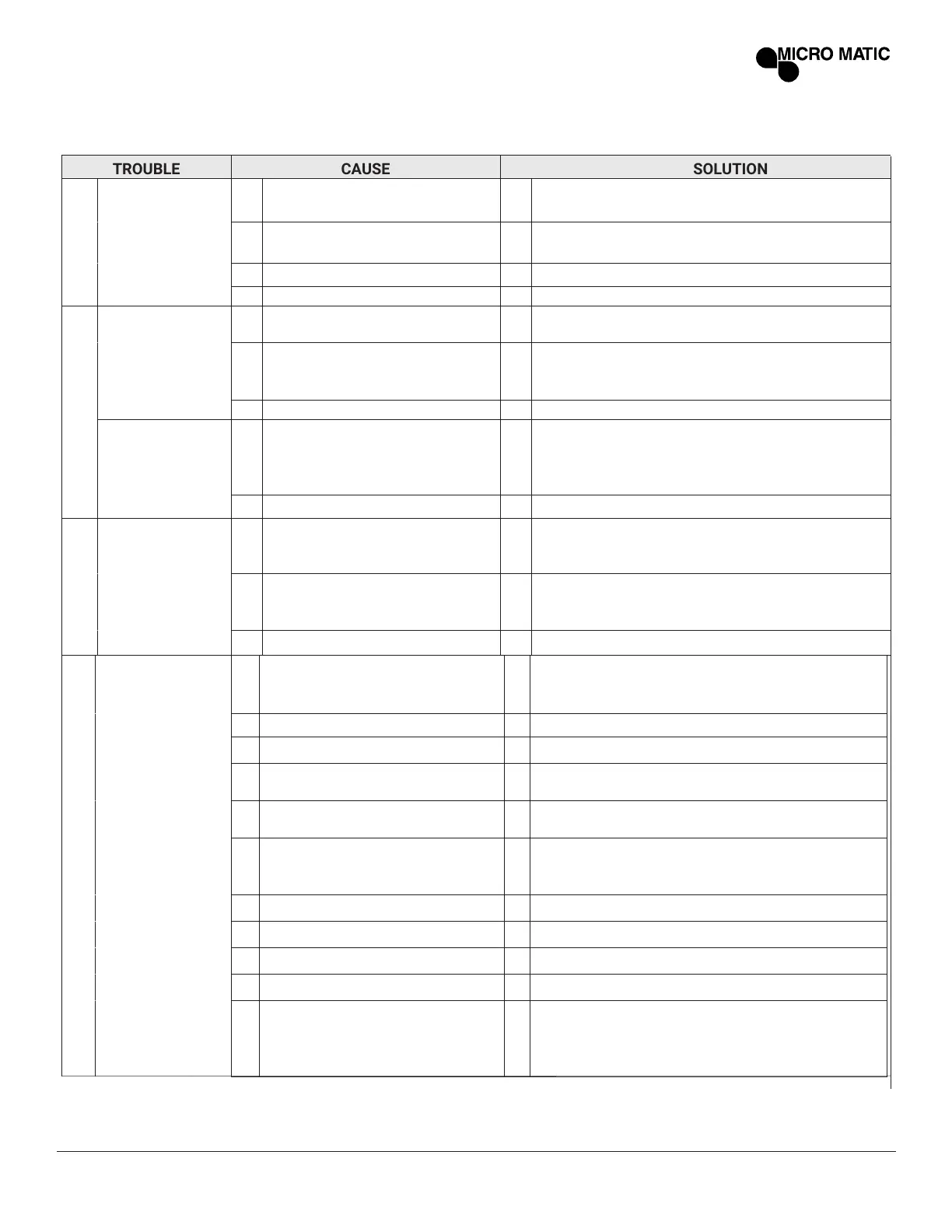

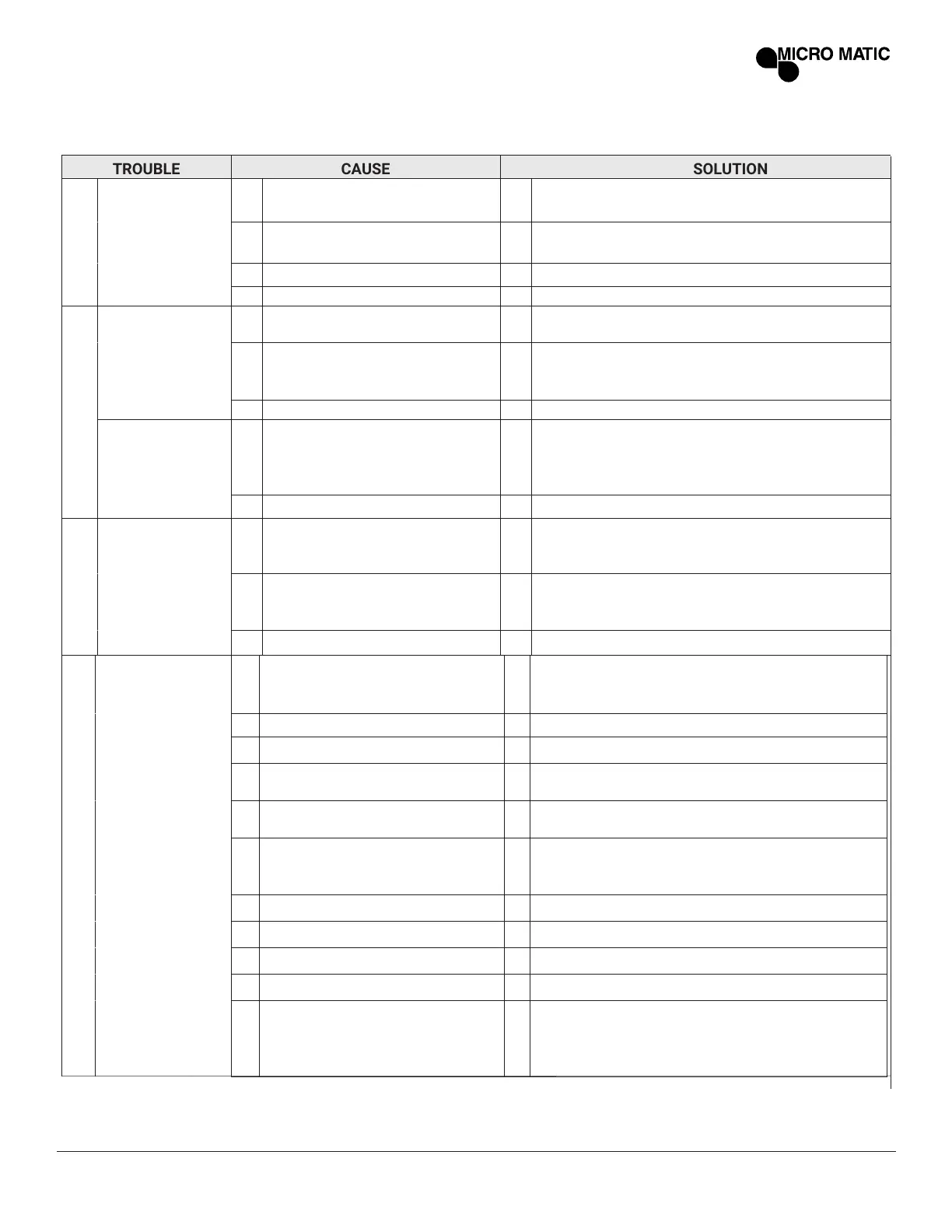

TROUBLESHOOTING

TROUBLE CAUSE SOLUTION

1. Excessive foam A.

Warm walk-in cooler

A.

Adjust cooler temperature to 36° to 38° F

(useaqualitythermometer)

B.

Check applied pressure to keg

B.

Adjustsettingonregulatorforproperowrateof

C. Checkequipment C. Checkthephysicalequipmentfromkegtofaucet

D. Warm product lines D. Refer to #5

2.

A. Compressor relay or capacitor

malfunction

A. Replace compressor relay or capacitor

B. Inadequatevoltage B. Measure voltage across common and run terminal

on compressor. Voltage must not drop below 90%

of rated voltage.

C. Compressor failure C. Replace compressor

Compressor starts

and continues to run

until freeze up and

will not cut off.

A. Thermostat control failure A. Replace thermostat

B. Freon leak B. Repair leak and recharge

4. Compressor does

not run but hums.

A. Inadequatevoltage A. Measure voltage across common and run terminal

on compressor. Voltage must not drop below 90%

of rated voltage.

B. Starting relay malfunction B. Replace starting relay. Be sure to use correct

relay. Failure to use correct relay will cause

compressor failure.

C. Compressor malfunction C. Replace compressor

5. Warm beer A.

Defective Pump

(check motor also)

A.

Checkreturnlineinreservoirforliquidow.Replace

pump on 125’, 250’, and 500’ units. Check condition of

key between pump and motor.

B. Defective motor (check pump also) B. Replace motor

C. Refrigeration unit not running

C.

Refer to #2

D.

Trunk lines located in

overheated area

D.

Remove from any hot water pipes or kitchen area with

stove or glass washer.

E.

Trunklinesoodedin

PVC chase.

E.

Remove lines from PVC, thoroughly dry PVC and repair or

replace trunk line as needed.

F. Uninsulated or poorly

insulated lines

F.

All lines should be fully insulated from cooler into

dispenser. Includes glycol lines from power pack into

cooler.

G. Thermostat

G. Adjust temperature to colder setting.

H. Condenser fan motor not working

H. Replace condenser fan motor

I. Freon Leak

I.

Repair leak and recharge

J. Dirty condenser

J.

Clean the condenser

K. Condensation inside trunk line

insulation (may be caused from

cleaning lines)

K. Check trunk housing in areas for drooping or low spots,

split insulation approximately 5" and separate. Allow any

water to drain, then air dry the seal closed.

Compressor does

not start (no hum),

but the fan

motor runs.

MICROMATIC.COM | 866-327-4159 POWER PACK SERVICE MANUAL | 13

two (2) ounces per second.

Loading...

Loading...