IBEX 8 Nozzle SMALL FRAME_June 2020 June 20 Page 22 of 41

10. SYSTEM MAINTENANCE

CRANKCASE OIL

The IBEX pump unit is equipped with an hour meter and an automatic

reminder to change pump oil; Red light, slow flash (does not affect

operation). See page 10 for instructions to reset light indicator.

Initially the Crankcase Oil must be changed after the first 50 operating

hours.

After that it should be changed after every 500 hours of operation.

Examples of 500 hours operation:

15 weeks of 5 hour operation per day

9 weeks of 8 hour operation per day

6 weeks of 12 hour operation per day

3 weeks of 24 hour operation per day

Chart to the right indicates oil capacity for each pump

SYNTHETIC 75w-90 GEAR OIL IS RECCOMENDED FOR ALL APPLICATIONS (Mobil One or Equal)

In the event that 75w-90 is not available, synthetic 15w-50 Motor oil may be substituted (Mobil One or

Equal)

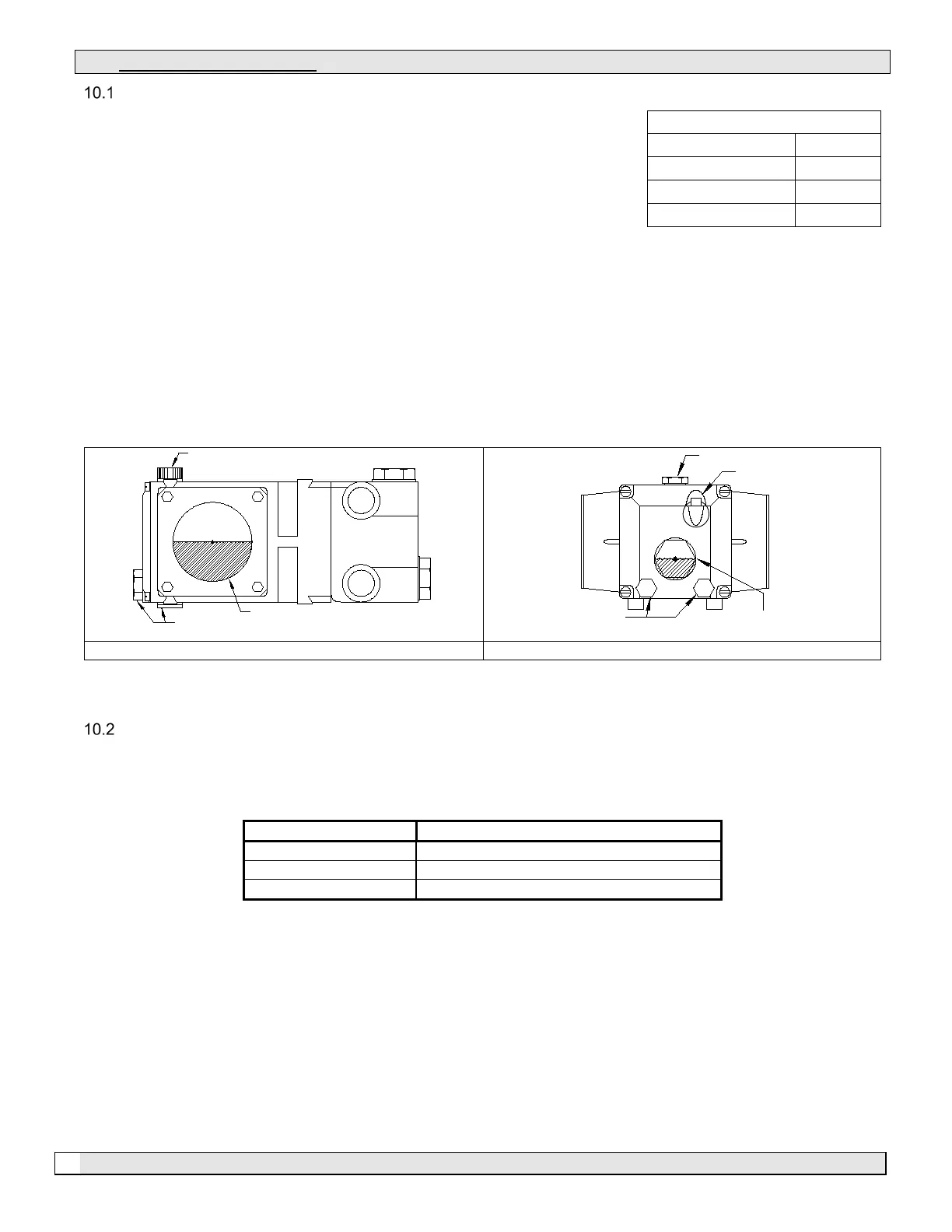

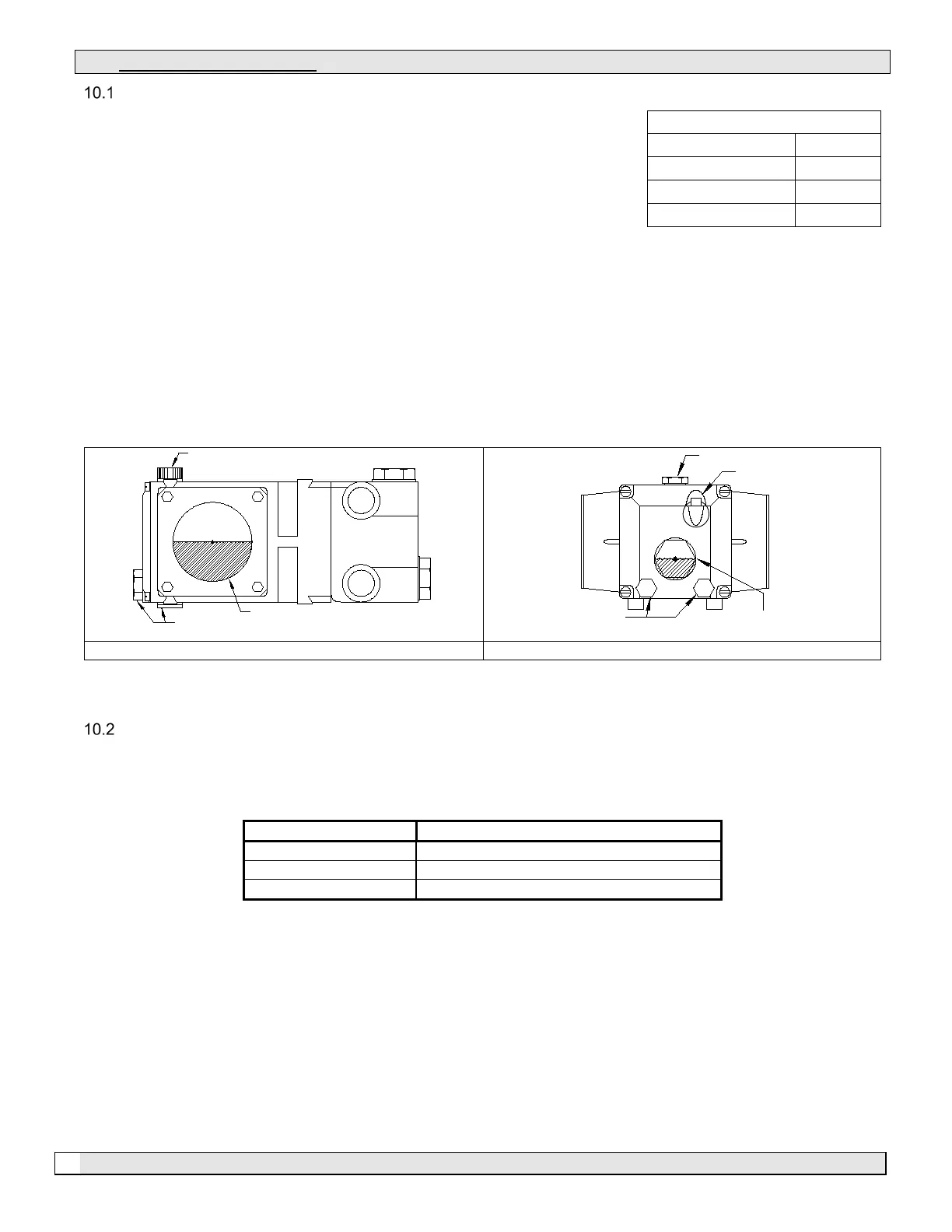

Figure 20 – Crankcase Oil Levels

ELECTRICAL MOTOR SERVICE

Two types of electrical motors are used on the MicroCool

pump modules. Some small motors have sealed

rotor bearings and some require lubrication periodically. Refer to the motor nameplate for the type of motor. If

the motor is equipped with external grease nipples refer to the chart below for lubrication instructions.

Lubricate at beginning of season

Electrical motors on the pump modules are pre-greased with a polyurea mineral oil NGLI grade 2-type grease

unless stated otherwise on the motor nameplate. Some compatible brands of polyurea mineral base type grease

are: Chevron SRI #2, Rykon Premium #2, Shell Oil Doilum R or Texaco Polystar RB. Motors are properly

lubricated at the time of manufacture and do not need to be lubricated at the time of installation.

NOTE: Over greasing bearings can cause premature bearing and/or motor failure. The amount of grease added

to the motor should be carefully controlled. One crank of the grease gun handle is usually sufficient.

FILL TO CENTER

OF SIGHT GLASSOIL DRAIN

OIL FILL AND DIPSTICK

FILL TO CENTER

OF SIGHT GLASS

OIL DRAIN

OIL FILL

OIL LEVEL

DIPSTICK

P200, P300 & P400 Giant Pump Series

P56, P59 Giant PumpSeries

Loading...

Loading...