FlowPrep 060 Troubleshooting

May 2010 4-1

4. TROUBLESHOOTING AND MAINTENANCE

The FlowPrep 060 requires very little maintenance to remain in top operating condition. The

gas flow tubes should be wiped clean after each use and inspected weekly to ensure that they

do not become clogged. This chapter contains instructions for inspecting and replacing gas

flow tubes, as well as a troubleshooting chart and other maintenance procedures.

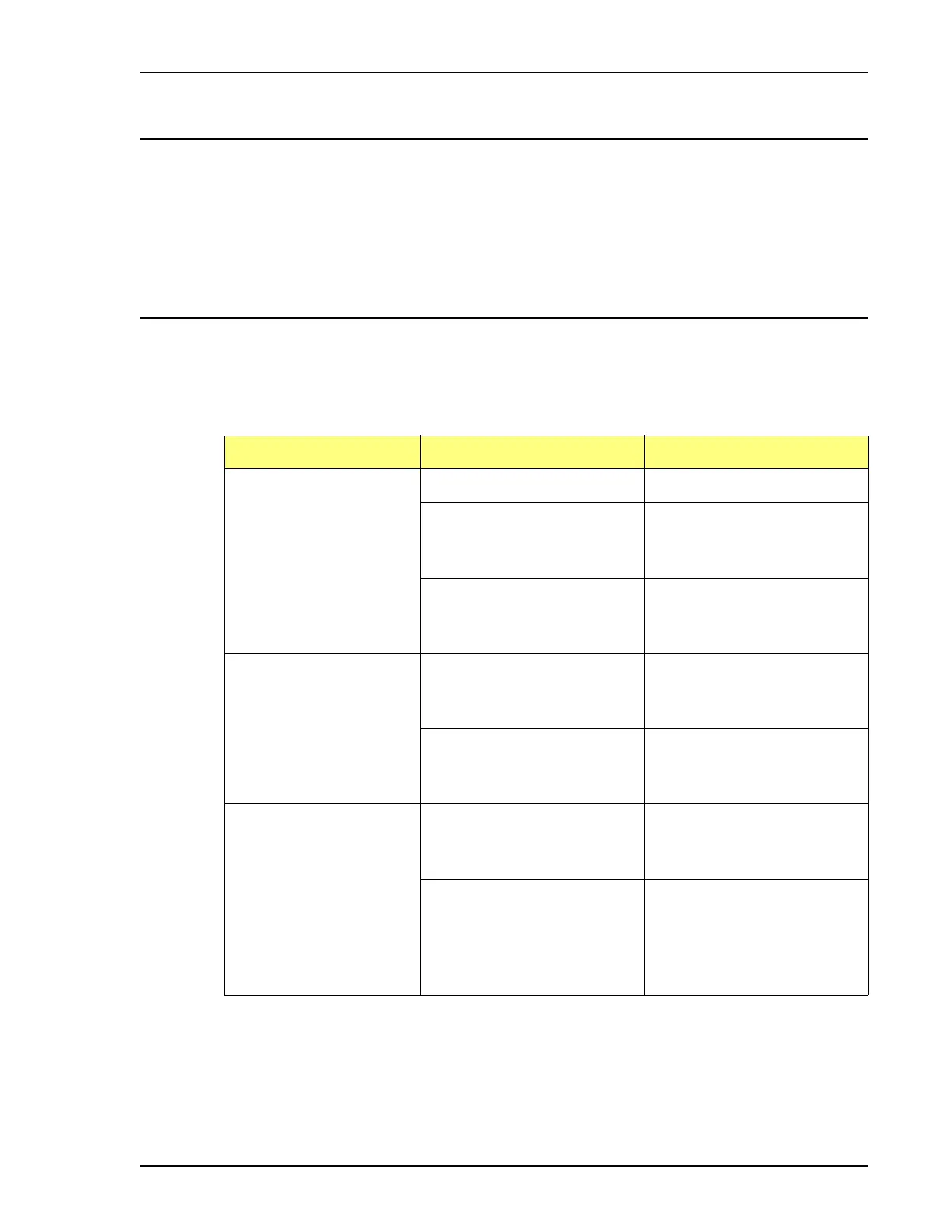

Troubleshooting

Operating problems encountered with the degasser are usually easily corrected. Typical prob-

lems and the steps required to correct them are described in the following table.

Table 4-1. Common Operational Problems

What Happened Why What To Do

Either no heat or

insufficient heat is being

supplied to the heating

stations.

Blown fuse. Replace fuse (see page 2-3).

A mistake was made in

entering the temperature set

point.

Enter the correct temperature

set point on the temperature

controller.

The thermocouple or other

internal component is damaged

or disconnected.

Call the appropriate service

personnel.

Too much heat is being

supplied to the heating

stations.

A mistake was made in

entering the temperature set

point.

Enter the correct temperature

set point on the temperature

controller.

The thermocouple or other

internal component is damaged

or disconnected.

Call the appropriate service

personnel.

A newly installed fuse is

blown.

Line voltage is too high. Check the line voltage, refer to

Selecting the Input Power,

page 2-2.

A fuse with the wrong rating

was installed.

Install the appropriate fuses for

the input power source: 100-

120 VAC - 2.5 A slow-blow;

220-240 VAC - 1.25 A slow-

blow.

Loading...

Loading...