PART 5 IMPORTANT NOTES

1. The carbon brush was adjusted before dispatch, they can feed automatically. Please do not adjust;

Note: After 100 working hours, check the wear condition. Replace the carbon brush if needed. If

the carbon brush wears out, please turn off the machine immediately, otherwise the motor will be

damaged. We suggest: when carbon brush wears 2/3, replace the carbon brushto aviod motor

damage.

2. If the tool bit is dull, bevel resistance will increase and spline shaft and/or motor and reducer

parts will be damaged. Please sharpen tool bit or replace with a new one.

If you sharpen the tool bit, one tool bit can be used multiple times

If the tool bit is dull and tool feed is too much it may cause the motor to stop. Turn off the power

immediately, otherwise the motor and machine may be damaged.

How to check if the tool bit is dull or sharp:

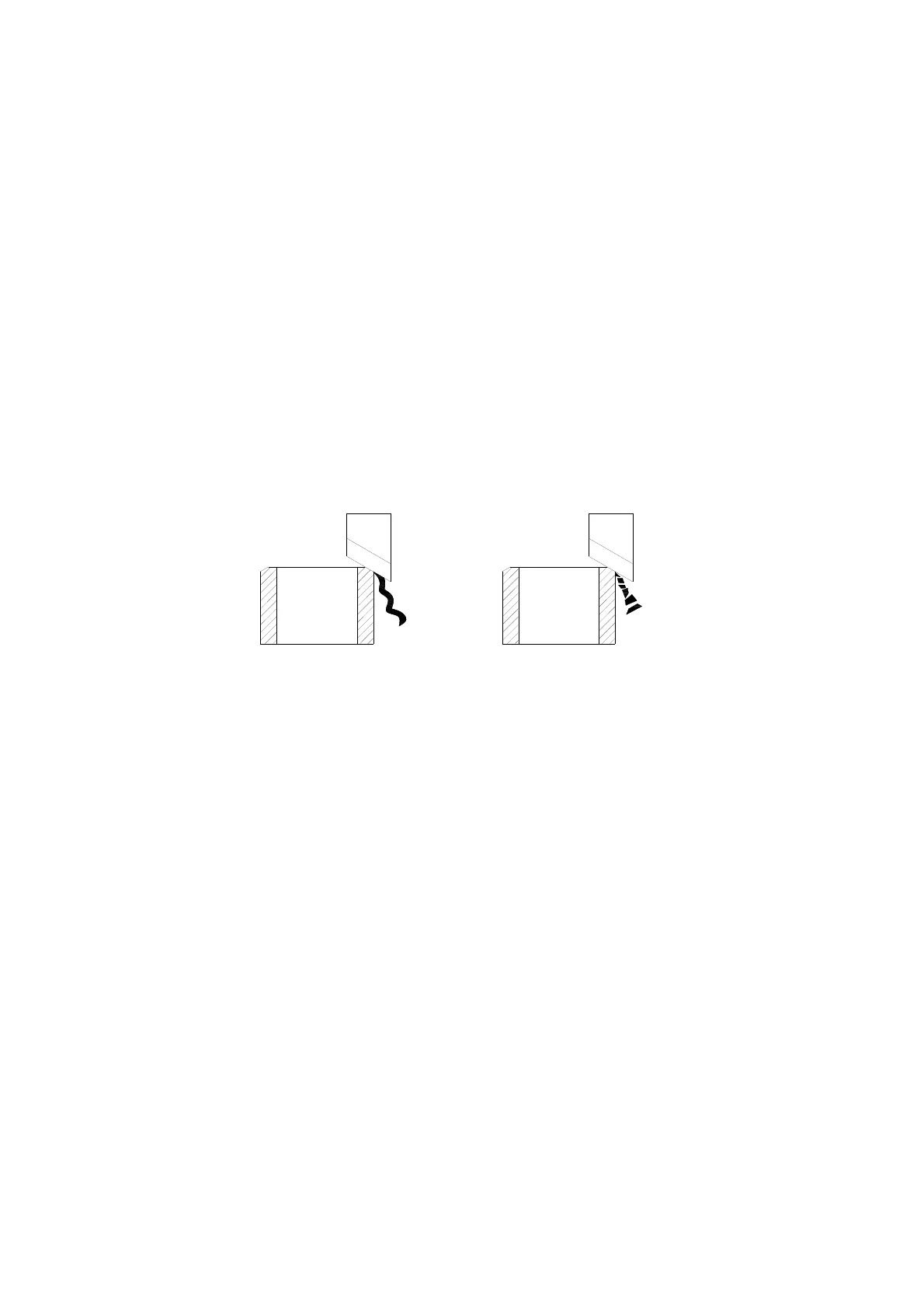

Figure 1: tool bit is sharp, scrap-iron is a strip

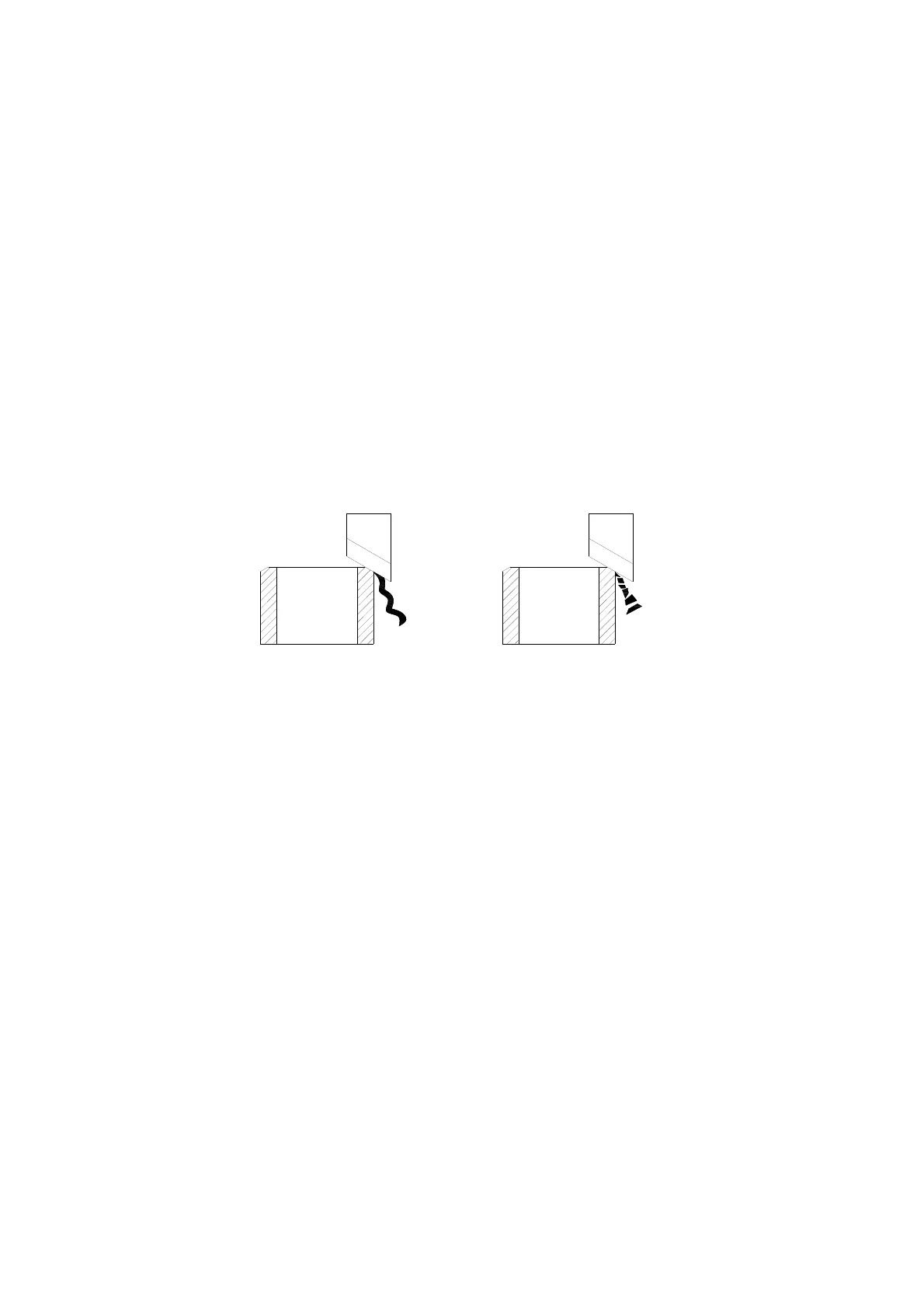

Figure 2: tool bit is dull, scrap-iron is fragment

3. Continue to spray coolant (saponification oil) while working to make the beveling smooth and

prolong the tool bit life

4. Before beveling, please remove the rough edge and other incidentals after flame cutting with

hammer. If the pipe end surface is full of bumps and holes, start at the high point, and feed the

tool bit carefully.

5. When working with small size tube, please use a bench clamp or other tool to fix the tube

6. BT6 and BT14 adopt a tool feed/back ratchet spanner, it is convenient for operator, but must

control the feed speed. If you feed too much it may damage machine.

7. Motor may stop which is caused by a dull tool bitor tool feed is too fast Cut-off the power supply

immediately, otherwise will damage the motor.

8. Operator must read this manual completely before operation, the damage caused by improper

operation will not be covered under warranty.

Loading...

Loading...