Atom B Series VRF 50/60Hz

74

Midea Atom B Series Engineering Data Book

3 Refrigerant Piping Design

3.1 Design Considerations

Refrigerant piping design should take account of the following considerations:

The amount of brazing required should be kept to a minimum.

On the two inside sides of the first indoor branch joint (“A” in Figures 3-3.4 and Figure 3-3.5) the system should, as far

as possible, be equal in terms of number of units, total capacities and total piping lengths.

3.2 Material Specification

Only seamless phosphorus-deoxidized copper piping that complies with all applicable legislation should be used. Temper

grades and minimum thicknesses for different diameters of piping are specified in Table 3-3.1.

Table 3-3.1: Piping temper and thickness

Piping outer diameter

(mm)

Notes:

1. O: coiled piping;

2. 1/2H: straight piping.

3.3 Connection Method

Various piping patterns can be selected, such as out from the front, the back the side, and undersurface, etc. (The follow

display the locations of several piping and wiring knock-off interfaces)

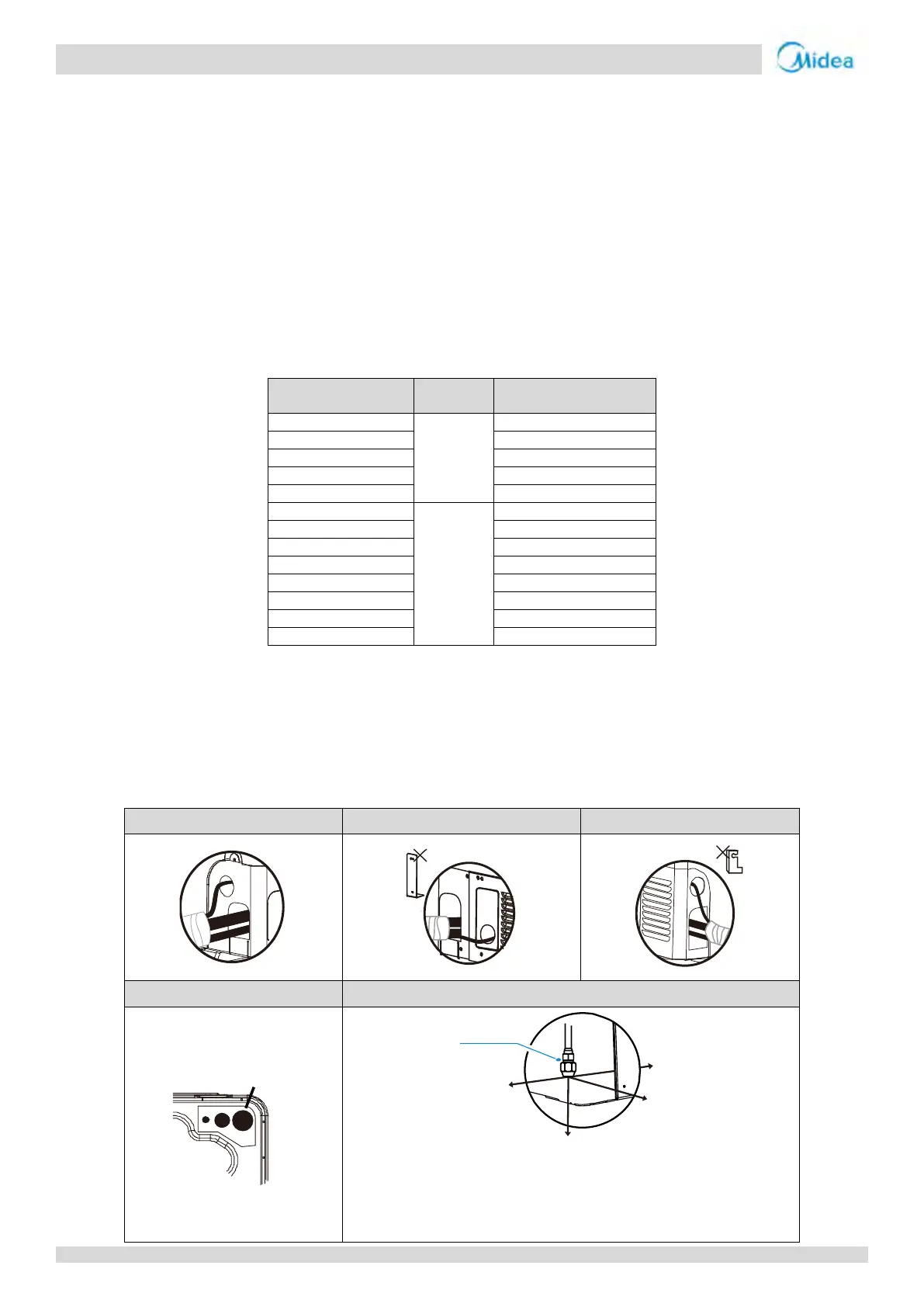

Table 3-3.2: The indoor and outdoor connecting pipe interface

The connect methond of flaring

For the 48kBtu/h outdoor unit's back out pipe connection, connecting pipe

is suggestted to be used. For the 56kBtu/h outdoor unit's, connecting pipe is

suggestted to be used in all directions out pipe connection

Front out

pipe

Bottom out

pipe

Back out

pipe

Side out

pipe

Connecting Pipe

(Accessorry)

Loading...

Loading...