Page 7

4.5 Electric Connection

Remove the electrical compartment cover on the right hand side

and connect the wires accordingly.

(Where possible terminate the electrical connection with a suitable

isolating switch (By authorised electrician)

• The power supply should be hard wired.

• Power supply circuit should be earthed effectively. The wiring

must be performed by professional technicians in accordance

with national wiring regulations and the circuit diagram.

• An all-pole disconnection device which has at least 3mm

separation distance in all pole and a residual current device

(RCD) with the rating of above 10mA shall be incorporated in

the fixed wiring according to the national rule.

• Set the electric leakage protector according to the relevant

electric technical standards of local regulations.

• All electrical works shall be properly run using suitable conduit

/ insulation without contacting any of the piping or valves.

• The power cord and the signal cord shall be laid out neatly

and properly without mutual interference or contact the

connection pipe or valve.

• After wire connection, check it again and make sure of

connection before power is turned on.

WARNING

The unit must be installed with an RCD near the power supply

and must be effectively earthed.

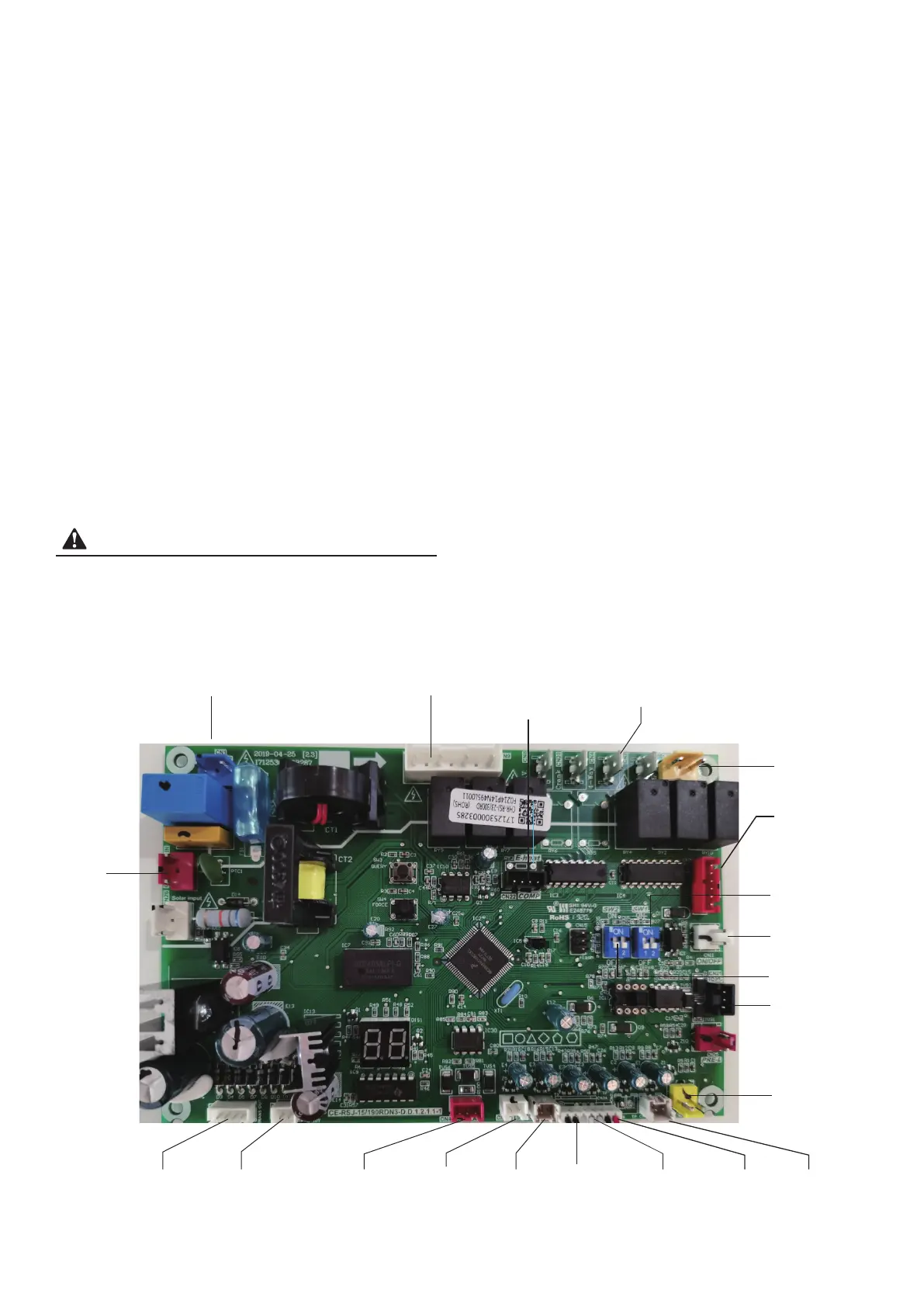

3.2.3 PCB I/O Ports description

Fig.3-4

Alarm

SW1 Factory Setting

for Disinfect

&Electric Heater

Model Selection

SW2 Factory Setting

for 190L/300L Model

Selection

High Pressure

Switch

Tp:Comp

Discharge

Temp.Sensor

Transformer

Output

Transformer

Input

Power Supply

Fan

To Comp. Relay

& E-heater Relay

4-way

Valve

Panel Display

Power Supply

Output

Panel Display

Output

T5L:Lower

Tank Water

Temp.Sensor

T5U:Upper

Tank Water

Temp.Sensor

T4:Ambient

Temp.Sensor

T3:Evaporator

Inlet Temp.

Sensor

Th:Comp

Suction

Temp.Sensor

EEV

ON/OFF

To computer

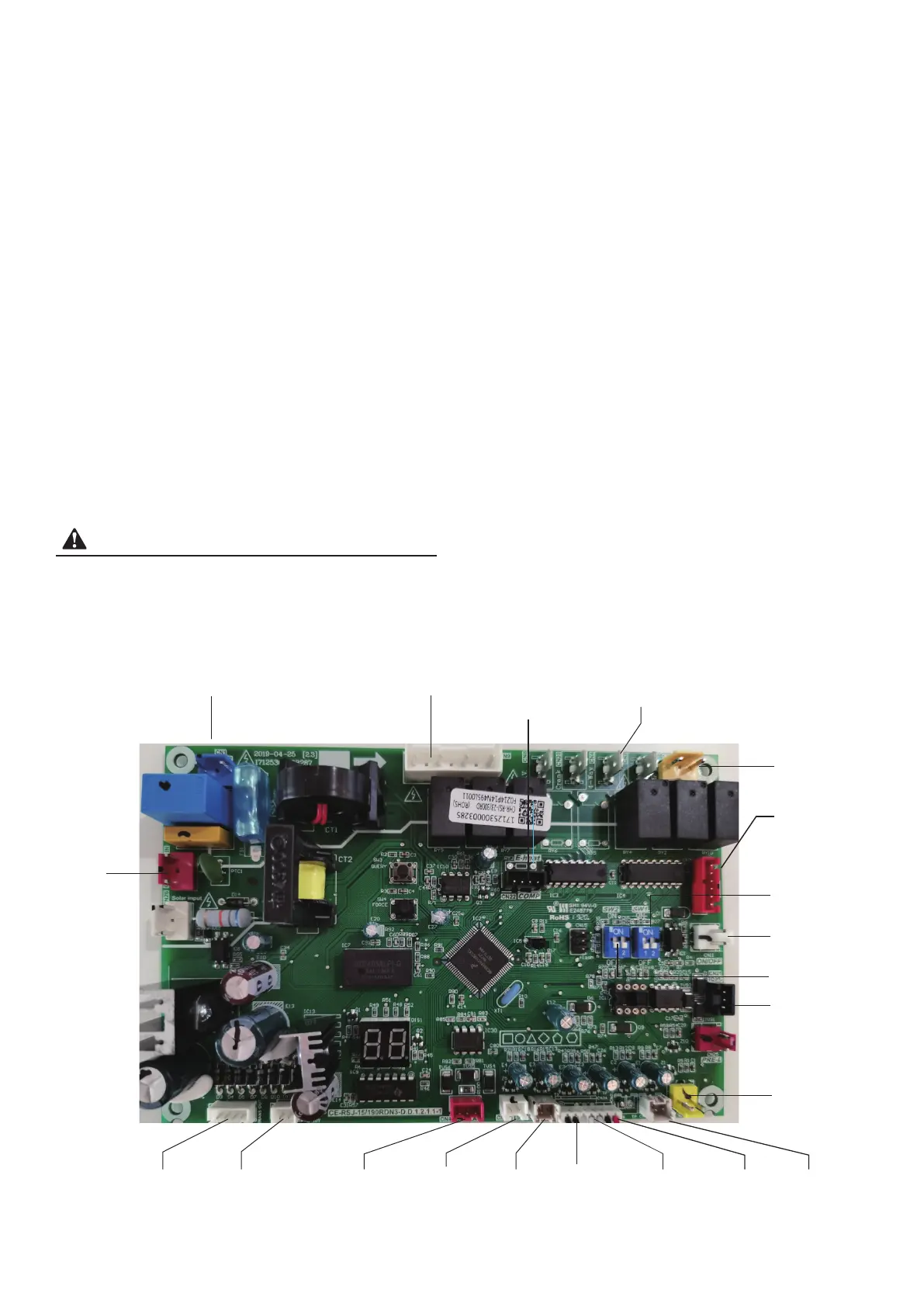

4.5.2 PCB I/O Ports Description

Loading...

Loading...