25

When a safety device is activated, an error code will be displayed on the user interface.

A list of all errors and corrective actions can be found in the table below.

Reset the safety by turning the unit OFF and back ON.

In case this procedure for resetting the safety is not successful, contact your local dealer.

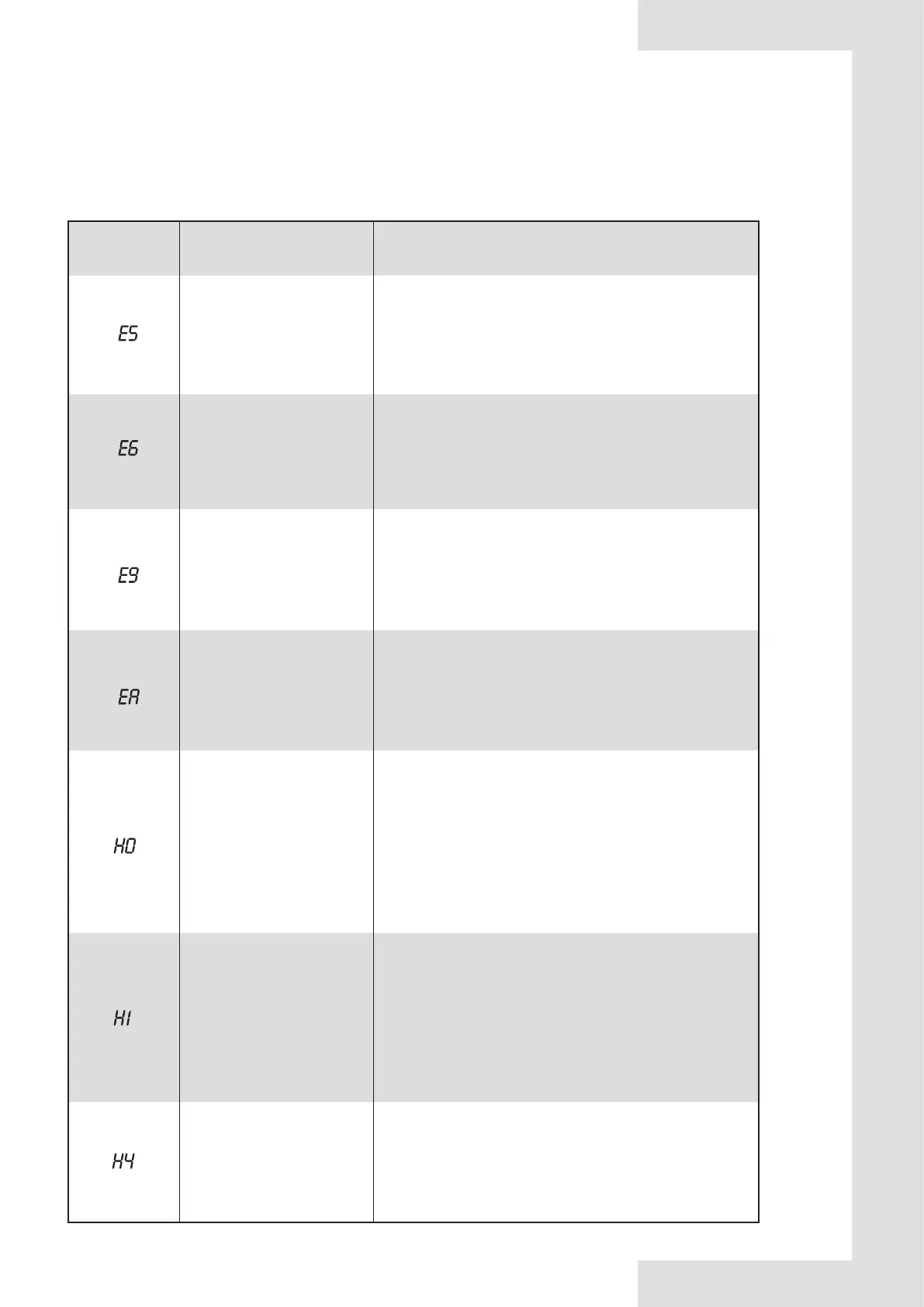

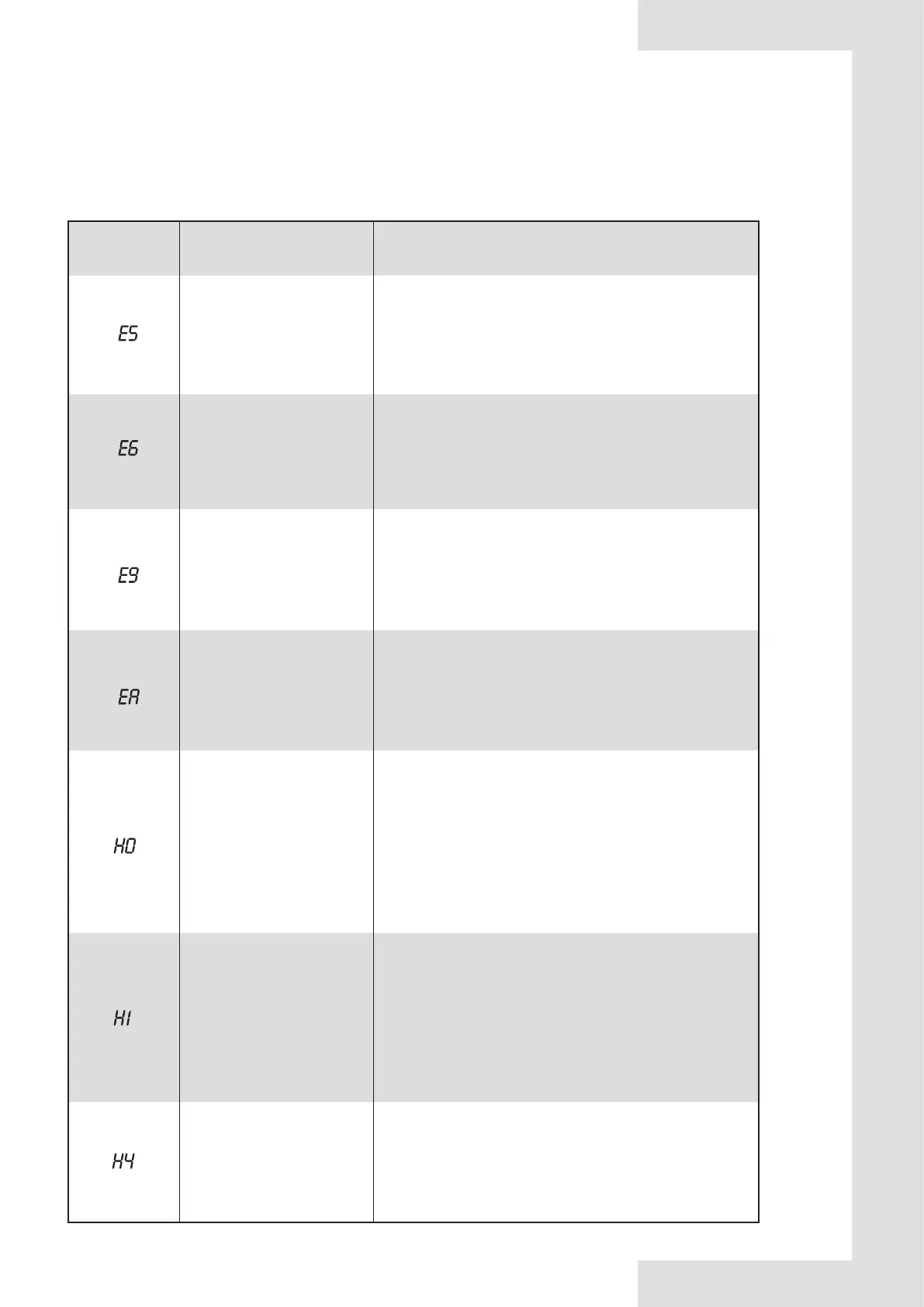

13.8 Error codes

ERROR

CODE

MALFUNCTION

OR PROTECTION

FAILURE CAUSE

AND CORRECTIVE ACTION

1. The T3 sensor connector is loosen. Reconnect it.

2.The T3 sensor connector is wet or there is water in. remove

the water, make the connector dry. Add waterproof adhesive

3. The T3 sensor failure, change a new sensor.

The condenser outlet

refrigerant temperature sensor

(T3)error.

1. The T4 sensor connector is loosen. Reconnect it.

2.The T4 sensor connector is wet or there is water in. remove

the water, make the connector dry. Add waterproof adhesive

3. The T4 sensor failure, change a new sensor.

The ambient temperature

sensor (T4) error.

1. The Th sensor connector is loosen. Re connect it.

2.The Th sensor connector is wet or there is water in. remove

the water, make the connector dry. Add waterproof adhesive

3. The Th sensor failure, change a new sensor.

Suction temperature

sensor(Th) error

1.wire doesn’t connect between main control board PCB B and

main control board of hydraulic module. connect the wire.

2.Communication wire sequence is not right. Reconnect the

wire in the right sequence.

3. Whether there is a high magnetic field or high power

interfere, such as lifts, large power transformers, etc.. To add a

barrier to protect the unit or to move the unit to the other place.

Communication error between

main control board PCB B and

main control board of

hydraulic module

1. The Tp sensor connector is loosen. Re connect it.

2.The Tp sensor connector is wet or there is water in. remove

the water, make the connector dry. Add waterproof adhesive

3. The Tp sensor failure, change a new sensor.

Discharge temperature

sensor(Tp) error

1. Whether there is power connected to the PCB and driven

board. Check the PCB indicator light is on or off. If Light is off,

reconnect the power supply wire.

2.if light is on, check the wire connection between the main

PCB and driven PCB, if the wire loosen or broken, reconnect

the wire or change a new wire.

3. Replace a new main PCB and driven board in turn.

Communication error between

inverter module PCB A and

main control board PCB B

Same to P6

Three times P6 protect

Loading...

Loading...