The site contains mineral oils such as cutting lubricant.

Seaside where the air contains much salt.

Hotpring area where corrosive gases exist, e.g., sulfide gas.

Factories where the supply voltage fluctuates seriously.

Inside a car or cabin.

Place like kitchen where oil permeates.

Place where strong electromagnetic waves exist.

Place where flammable ga ses or materials exist.

Place where acid or alkali gases evaporate.

Other special environments.

Install the unit where enough space of installation and

maintenance is available.

Install the unit where the air inlet and air outlet are free from

obstacles and strong wind.

Install the unit in a dry and well ventilated place.

Install the unit where the bearing surface is level and can bear

weight of the unit, and is suitable for installing the unit

horizontally without increasing noise or vibration.

Install the unit where the operation noise and the expelling of air

do not affect neighbours.

Install the unit where no flammable gas is leaked.

Install the unit where it is convenient for pipe connection and

electric connection.

2

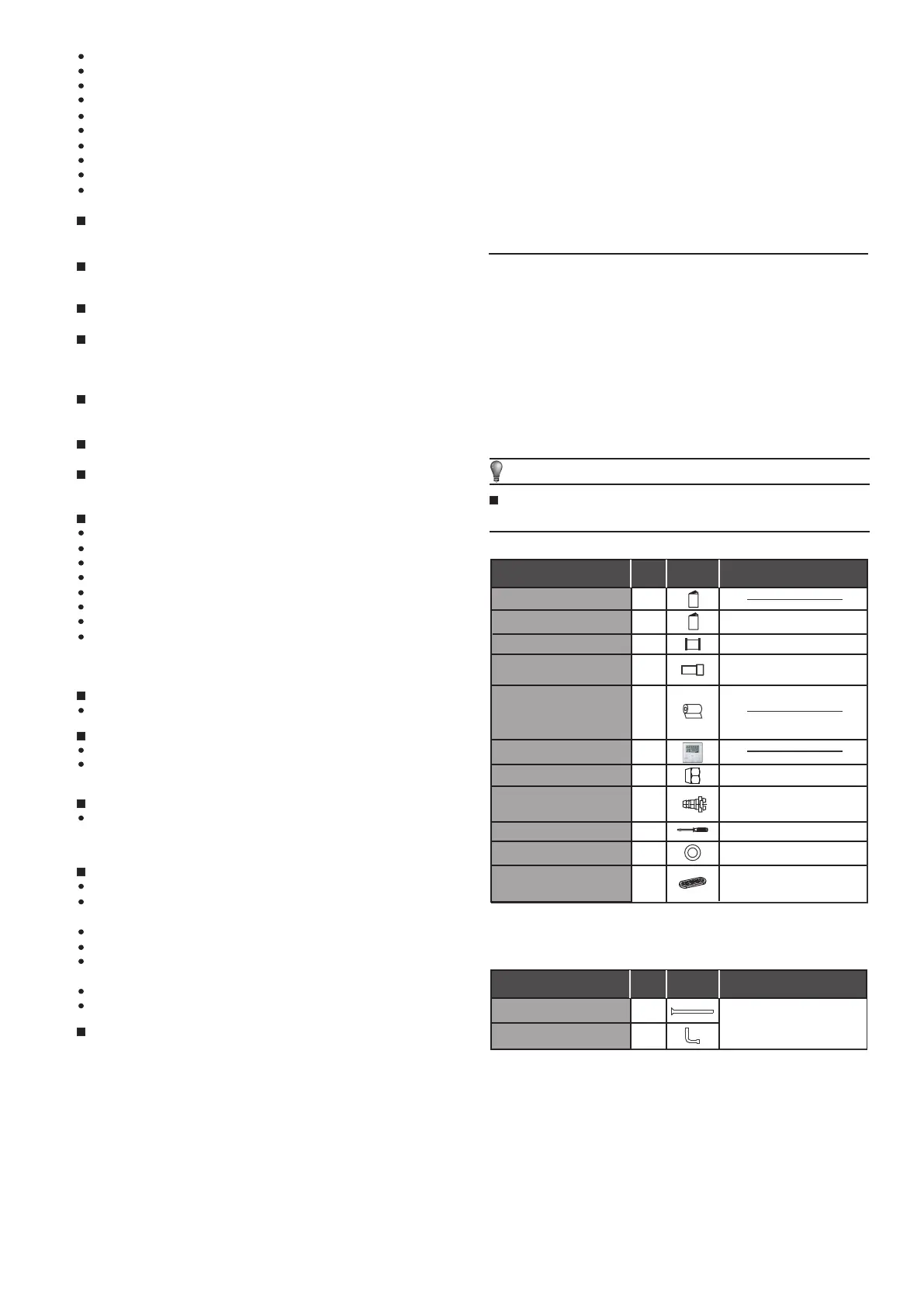

2. ACCESSORIES

NOTE

If in the wire control mode, the accessories do not include

display panel assembly remote controller or mounting bracket.

1

1

1

2

2

1

Accessory name of

indoor unit

Qty. Purpose

Owner’s manual

Shape

Installation manual

Sealing tape

Protective sleeve for

refrigerant inlet and

outlet pipes

Wired remote controller

Water connective pipe

This manual

Sealed tube interface

Connect to water drainage

pipe

Table 2-1

1

Copper nut

Connect to liquid-side pipe

Table 2-2

1

1

1

2

1

1

Accessory name of

outdoor unit

Qty. Purpose

Water outlet connection

pipe

Shape

Straight screwdriver

Sealing ring

Connection pipe

Waterproof chassis cover

Centralized drainage

Inspection and DIP

Centralized drainage

Chassis auxiliary drainage

plug

Curved connection pipe

Connecting pipe of system

13) Flare tool

14) Pipe bender

15) Level vial

16) Metal saw

17) Gauge manifold (Charge hose:R410A special requirement)

18) Vacuum pump (Charge hose:R410A special requirement)

19) Torque wrench

1/4(17mm)16N•m (1.6kgf•m)

3/8(22mm)42N•m (4.2kgf•m)

1/2(26mm)55N•m (5.5kgf•m)

5/8(15.9mm)120N•m (12.0kgf•m)

20) Copper pipe gauge adjusting projection margin

21) Vacuum pump adapter

Required tools for installation work

1) Philips screw driver

2) Hole core drill(65mm)

3) Spanner

4) Pipe cutter

5) Knife

6) Reamer

7) Gas leak detector

8) Tape measure

9) Thermometer

10) Mega-tester

11) Electro circuit tester

12) Hexagonal wrench

Refrigerant Piping

Piping kit used for the conventional refrigerant cannot be used.

Use copper pipe with 0.8 mm or more thickness for φ9.5mm.

Use copper pipe with 1.0 mm or more thickness for φ15.9mm.

Use copper pipe with 1.0 mm or more thickness for φ19.0mm.

Use copper pipe with 1.0 mm or more thickness for φ22.0mm.

Use copper pipe with 1.0 mm or more thickness for φ25.0mm.

Use copper pipe with 1.0 mm or more thickness for φ28.0mm.

Flare nut and flare works are also different form those of the

conventional refrigerant.take out the flare nut attached to the

main unit of the air conditioner, and use it.

Before installation

Be careful to the following items before installation.

Air purge

For air purge, use a vacuum pump.

Do not use refrigerant charged in the outdoor unit for air purge.

(The refrigerant for air purge is not contained in the outdoor unit.)

Electrical cabling

Be sure to fix the power cables and indoor/outdoor connecting

cables with clamps so that they do not contact with the cabinet,

etc.

Installation Place

A place which provides a specified space around the outdoor unit.

A place were the operation noise and discharged air are not

given to your neighbors.

A place that is not exposed to a strong wind.

A place that does not block a passage.

When the outdoor unit is installed in an elevated position, make

sure it's four feet securely installed.

There must be sufficient space for carrying in the unit.

A place where the drain water does not make any problem.

Loading...

Loading...