24

Dryer

Safety

Operation

Requirements

Parts and

Features

Installation

Instructions

Dryer Use

Appendix

Dryer Care

Troubleshooting

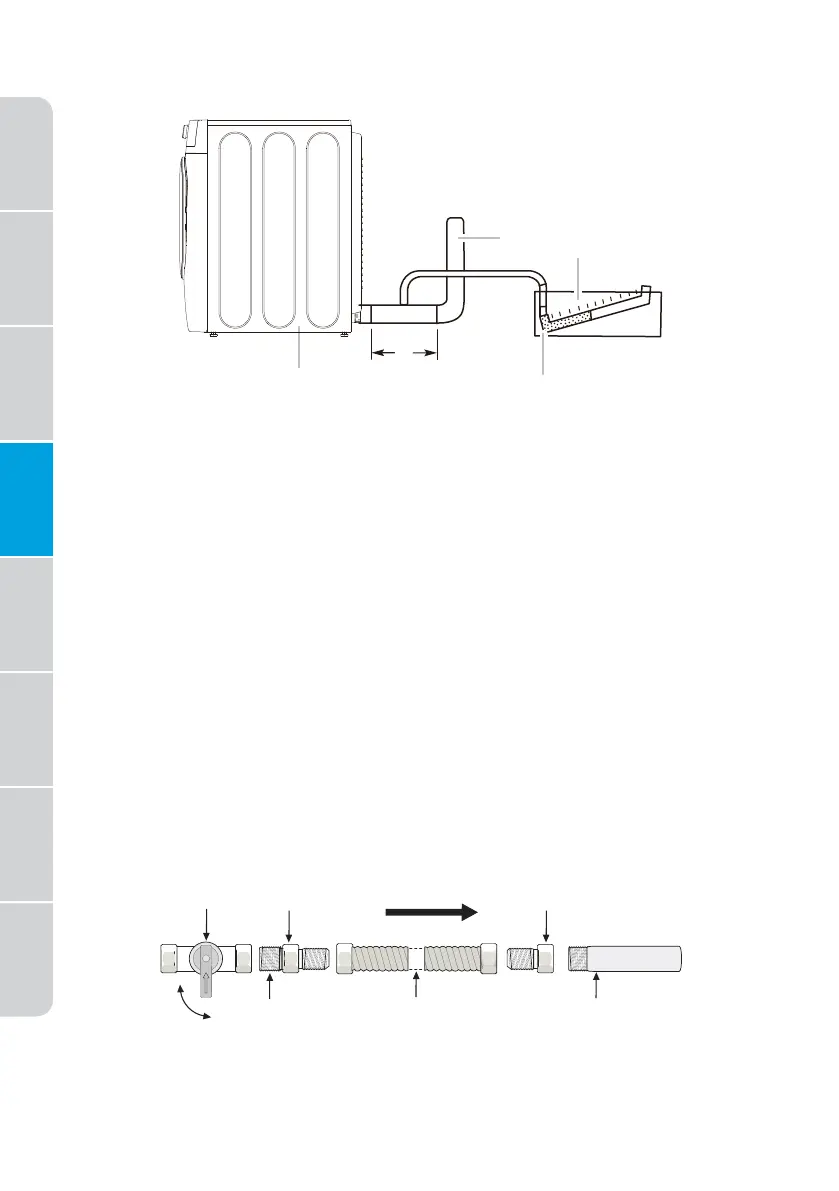

MEASURING AND VERIFYING ACTUAL SYSTEM BACK PRESSURE

a

b

c

d

a Dryer - empty and running on Air

Fluff cycle

b 10" (254 mm) min. of straight

pipe - measure back pressure

from the center

c To vent system

d Location on back

pressure measurement

e Inclined manometer

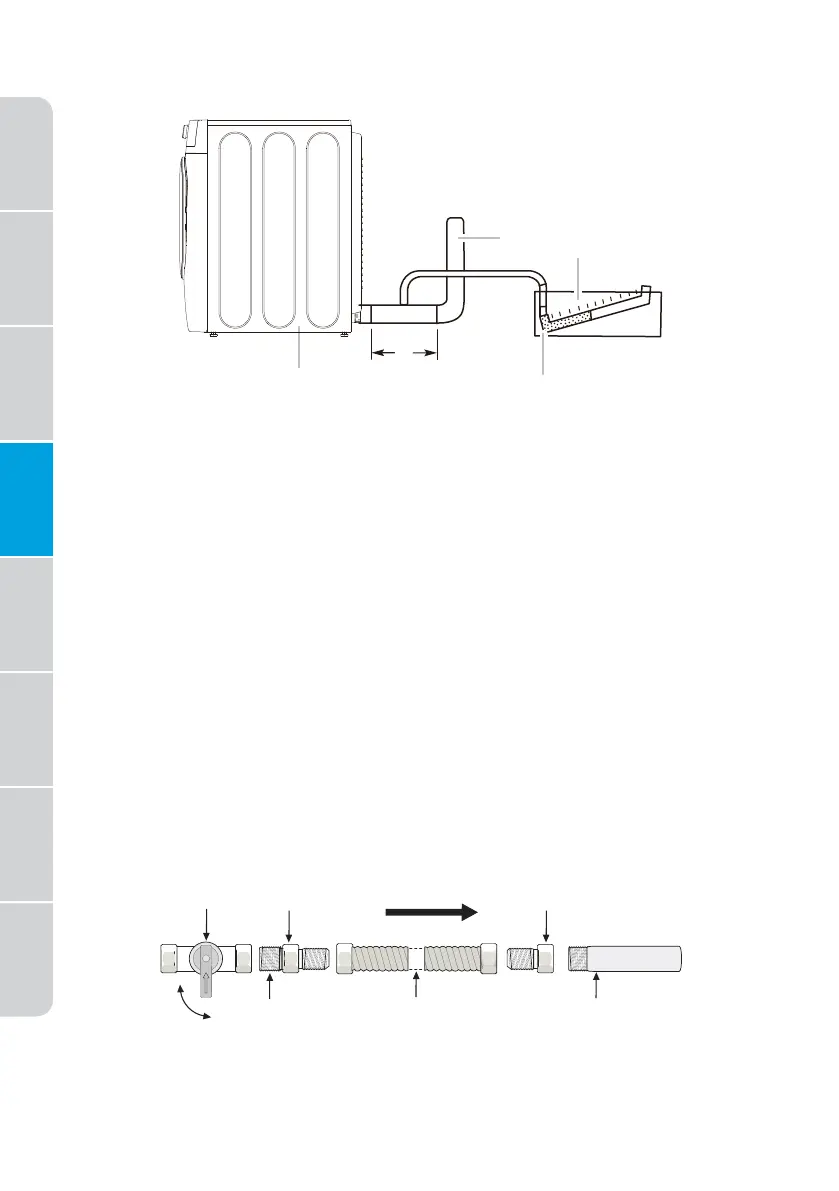

CONNECT THE GAS LINE (FOR GAS MODELS)

Review the “Gas Requirements” section on page 15. Remove the pipe

thread protective cap.

Apply a pipe joint compound or about 1 " wraps of teflon tape over all

threaded connections.

•

The pipe joint compound must be resistant to the actions of any

liquefied petroleum gas.

Connect the gas supply to your dryer. An additional fitting is required

to connect the " (1.9 cm) female thread end of a flexible connector to

the " (1 cm) male threaded end on the dryer. Use only new AGA or CSA

certified gas supply line with SS flexible connectors. within 6 ft (1.8 m) of

the dryer

Securely tighten the gas line fitting over the threads.

Turn on the gas supply.

S h u t o f f

V a l v e

Fl a r e

U n i o n

Fl a r e

U n i o n

O p e n

N i p p l e Fl e x i b l e

Co n n e c t o r

I n l e t P i p e o n

Ba c k o f Dr y e r

GAS FLOW

Al l c o n n e c t i o n s m u s t b e w r e n c h - t i g h t e n e d

Loading...

Loading...