13

6.4 Installation for the first time

Air and moisture in the refrigerant system have

undesirable effects as below:

● Pressure in the system rises.

● Operating current rises.

● Cooling or heating efficiency drops.

● Moisture in the refrigerant circuit may

freeze and block capillary tubing.

● Water when mixed with the refrigerant and oil

will create an acid that will damage the motor

windings and components in the refrigerant

system.

Therefore, the indoor units and the pipes

between indoor and outdoor units must be leak

tested and evacuated to remove gas and

moisture from the system.

Gas leak check (Soap water method):

Apply soap water or a liquid neutral

detergent on the indoor unit connections or

outdoor unit Connections with a soft brush to

check for leakage of the connecting points of

the piping. If bubbles come out, the pipes have

leakage.

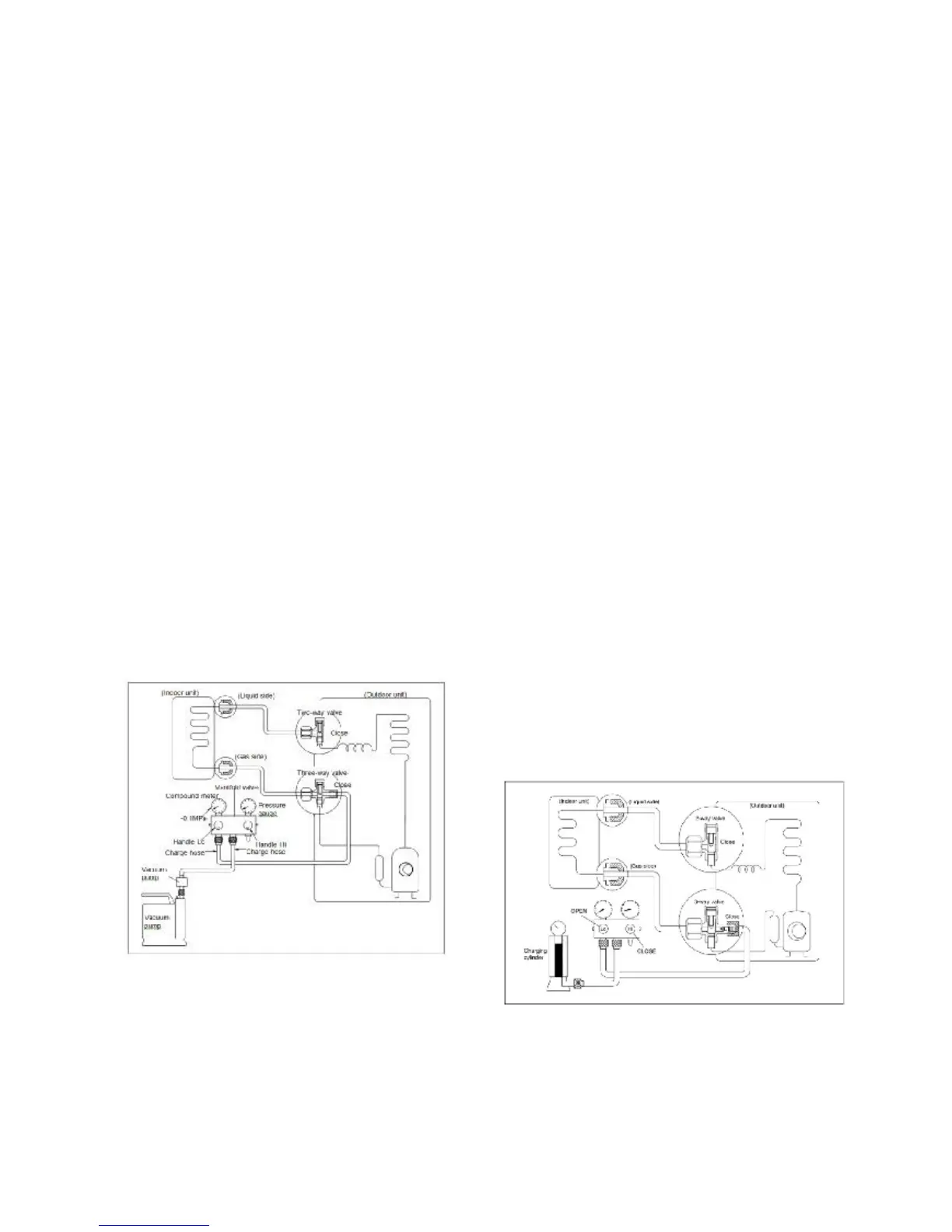

1. Air purging with vacuum pump

1) Completely tighten the flare nuts of the

indoor and outdoor units, confirm that both

the 2-way and 3-way valves are set to the

Front seated.

2) Connect the low pressure gauge to the 3 way

service valve access port..

3) Connect the middle hose of the gauge

manifold (usually yellow) to the vacuum

pump.

4) Fully open the handle for the low pressure

gauge..

5) Start the vacuum pump and operate according

to manufacture spec's.

6) Perform an evacuation for a minimum of 30

minutes and check that the low pressure

(compound) gauge indicates a vacuum of 29.9

in/hg (500 microns) A vacuum gauge should

be used if available. If the proper vacuum

cannot be achieved the vacuum pump should

be run for an additional 20 minutes. If after the

additional 20 minutes the vacuum still cannot

be achieved the is a leak in the system and

must be located and repaired. follow the leak

checking procedure as mentioned before. If

the vacuum is achieved, close the low pressure

gauge handle off and shut the vacuum pump

off. Recheck the reading after 10 minutes, the

vacuum may change slightly, this is normal.

7) The system is now dry and free of

contaminates, refrigerant pressure should

now be added to the system from a source

other than the system before opening the 2

way and 3 way valves for system operation.

8) The 2 way and 3 way valve can now be

opened for the system operation

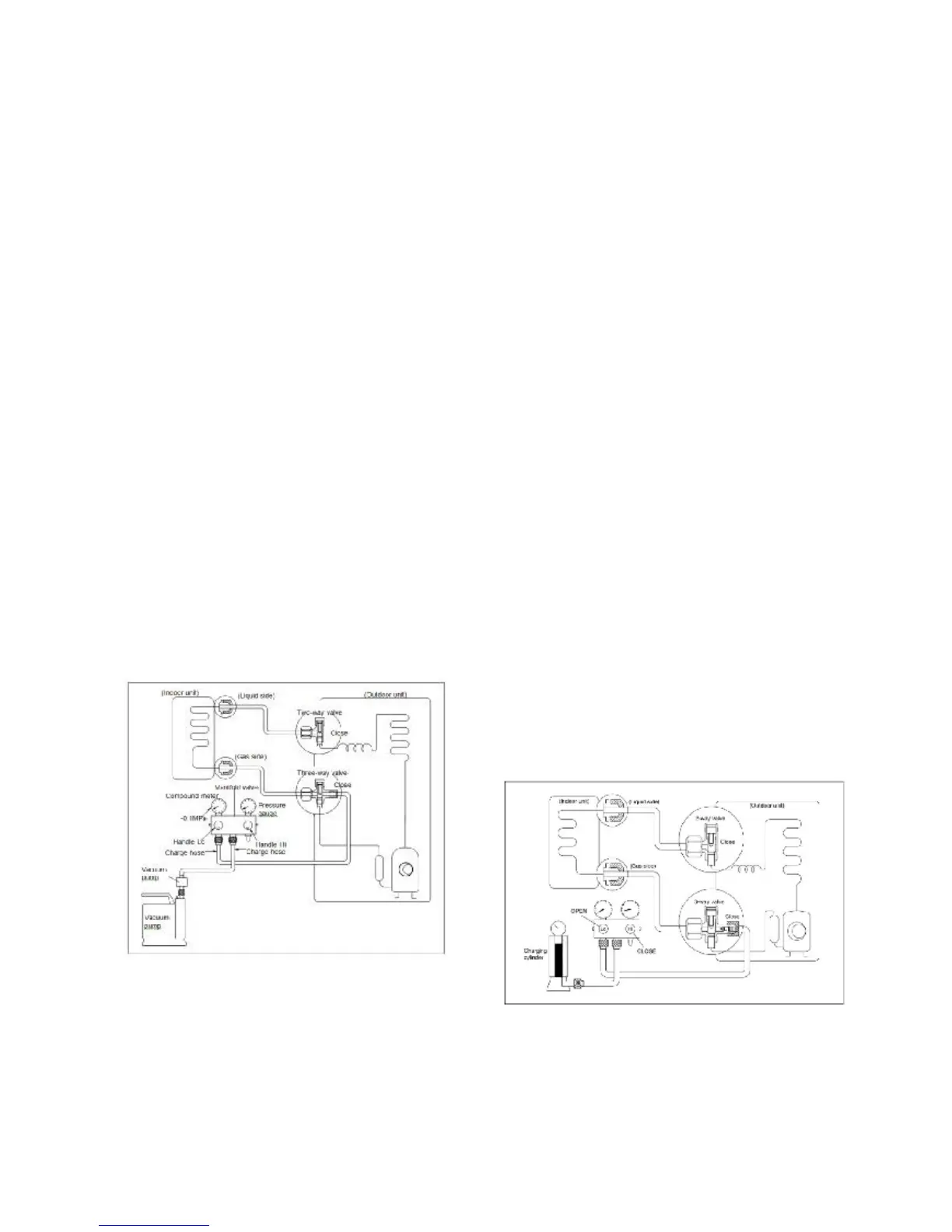

2. Air purging by refrigerant

Procedure:

1). Confirm that both the 2-way and 3-way

valves are set to the closed position.

2). With a container of refrigerant and a gauge

manifold set, connect the low pressure gauge hose

Loading...

Loading...