3 Refrigerant Piping Design

3.1 Design Considerations

Refrigerant piping design should take account of the following considerations:

The amount of brazing required should be kept to a minimum.

On the two inside sides of the first indoor branch joint (“A” in Figures 3-3.2, 3-3.3 and 3-3.4) the system should, as far

as possible, be equal in terms of number of units, total capacities and total piping lengths.

3.2 Material Specification

Only seamless phosphorus-deoxidized copper piping that complies with all applicable legislation should be used. Temper

grades and minimum thicknesses for different diameters of piping are specified in Table 3-3.1.

3.3 Permitted Piping Lengths and Level Differences

The piping length and level difference requirements that apply are summarized in Table 3-3.2 and are fully described as

follows (refer to Figure 3-3.2):

1. Requirement 1: The total length of piping in one refrigerant system should not exceed 150m.

2. Requirement 2: The piping between the farthest indoor unit (N6) and the outdoor unit should not exceed 100m (actual

length) and 110m (equivalent length). (The equivalent length of each branch joint is 0.5m.)

3. Requirement 3: The piping between the farthest indoor unit (N6) and first indoor branch joint (A) should not exceed

40m in length.

4. Requirement 4: Indoor auxiliary pipes (a to f) should not exceed 15m in length.

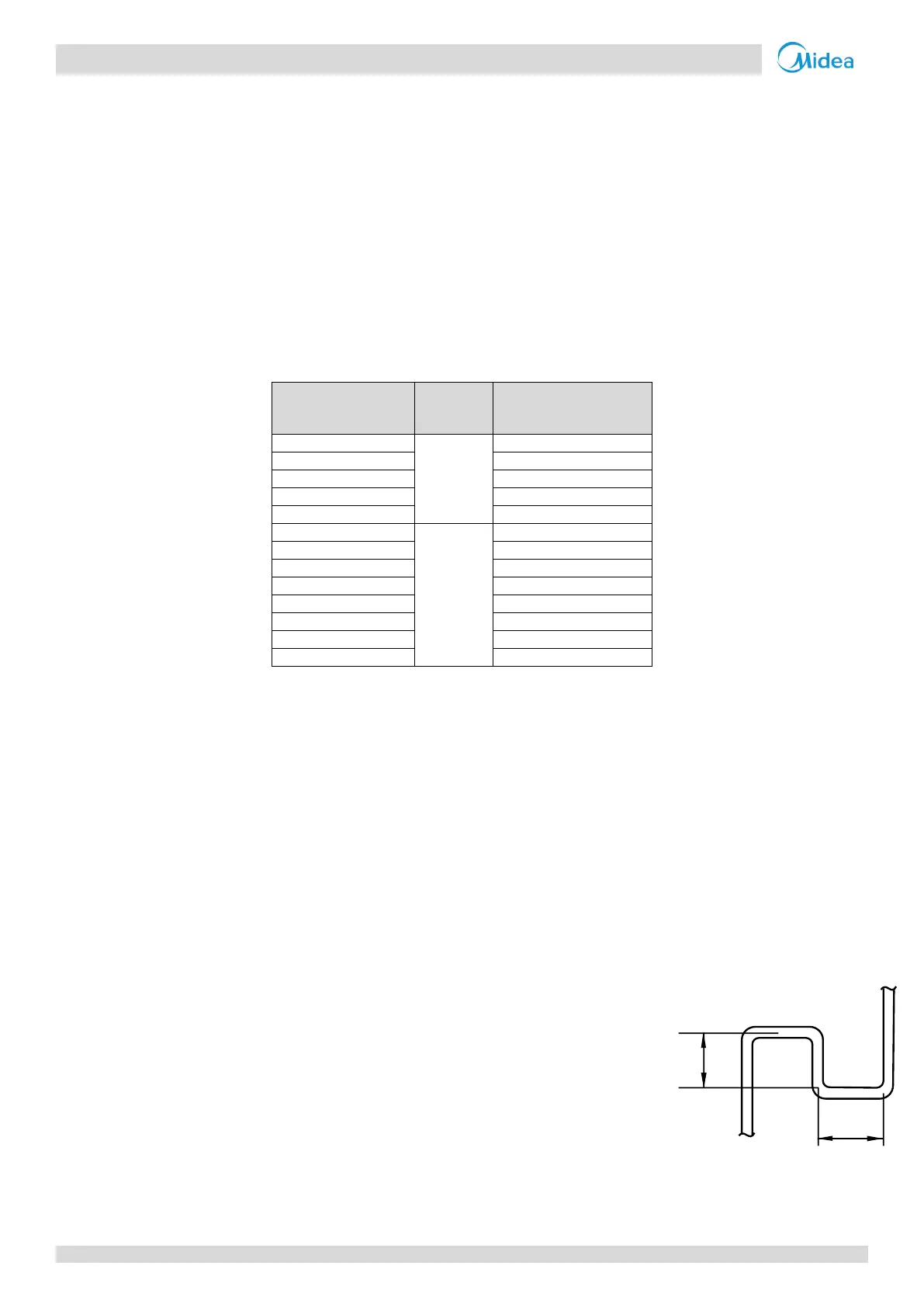

5. Requirement 5: The largest level difference between indoor unit and outdoor

unit should not exceed 50m (if the outdoor unit is above) or 40m (if the outdoor

unit is below). Additionally: If the outdoor unit is above and the level difference

is greater than 20m, it is recommended that an oil return bend with dimensions

as specified in Figure 3-3.1 is set every 10m in the gas pipe of the main pipe.

6. Requirement 6: The largest level difference between indoor units should not

exceed 15m.

Loading...

Loading...