. A complete Parts List is available at www.MillerWelds.com

OM-283935 Page 32

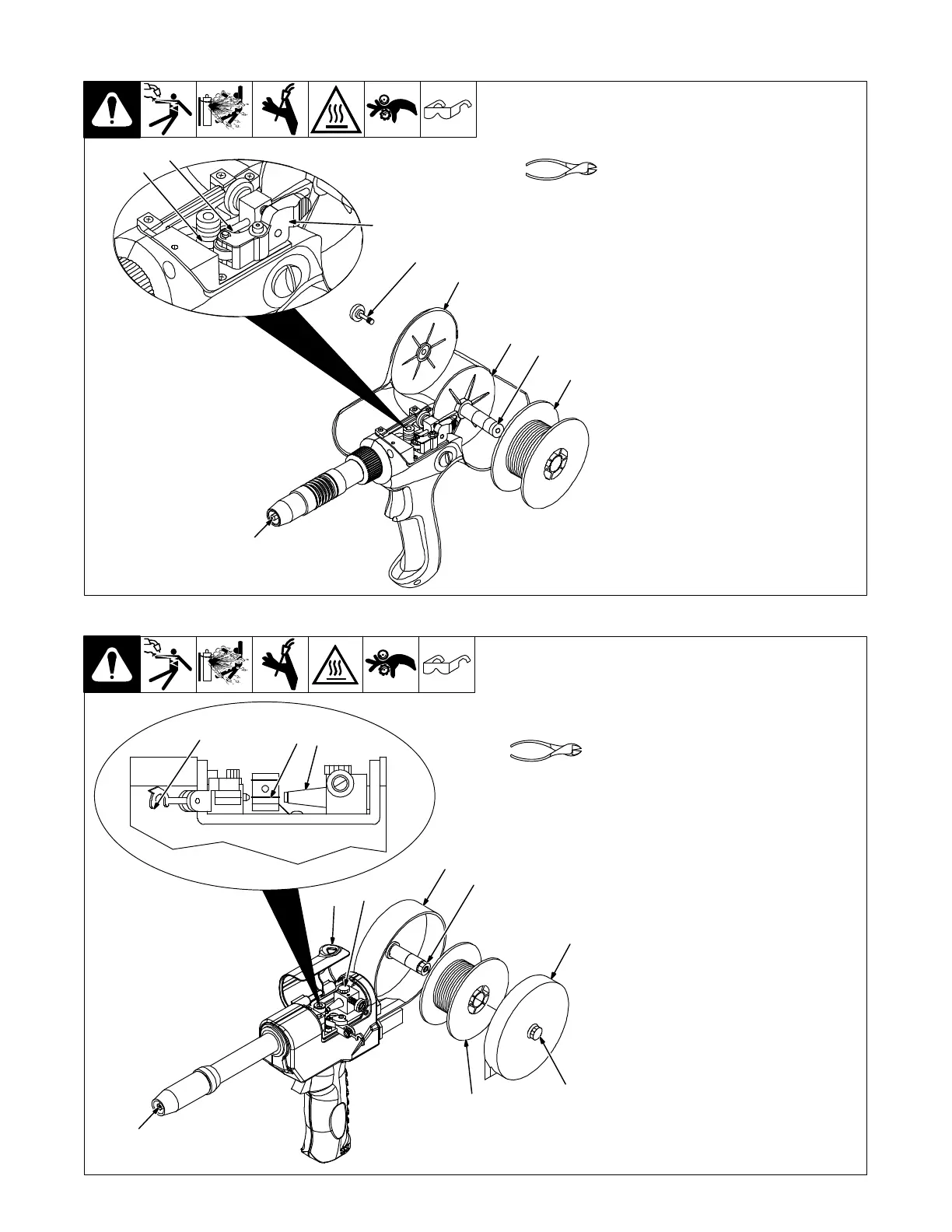

5-19. Threading Welding Wire For Spoolmate 200

Ref. 243 740-C

1 Cover

2 Canister

3 Thumbscrew (Cover)

Loosen thumbscrew, and rotate

cover open.

4 Wire Spool

Loosen wire from spool, cut off bent

wire, and pull 6 in (150 mm) of wire

off spool.

5 Pressure Roll Assembly

Press arm inward to open pressure

roll assembly.

6 Wire Inlet Guide

7 Drive Roll Groove

8 Contact Tip

Thread wire through wire inlet

guide, along drive roll groove, and

out contact tip.

Install spool so wire feeds off top.

9 Spool Brake Thumbnut

If necessary, turn thumbnut

counterclockwise slightly to install

spool.

Close cover and secure with

thumbscrew.

Tools Needed:

8

1

2

9

3

4

6

5

7

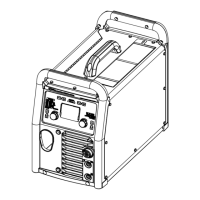

5-20. Threading Welding Wire For Spoolmatic 15/30A

150 436-F

1 Top Cover

2 Canister

3 Canister Cover

4 Thumbscrew (Canister Cover)

Loosen thumbscrew and remove cover.

5 Wire Spool

Loosen wire from spool, cut off bent wire,

and pull 6 in. (150 mm) of wire off spool.

6 Pressure Roll Assembly

Lift arm and open pressure roll assembly.

7 Canister Inlet Guide

8 Drive Roll Groove

. For wire sizes .035 in. (0.9 mm) and

smaller use small groove, and .047

in. (1.2 mm) and 1/16 in (1.6 mm) use

large groove.

9 Contact Tip

Thread wire through canister inlet guide,

along drive roll groove, and out contact

tip.

Install spool so wire feeds off bottom.

10 Spool Brake Thumbnut

If necessary, turn thumbnut counter-

clockwise slightly to install spool.

11 Thumbscrew (Canister Rotation)

Loosen thumbscrew to rotate canister.

Close and secure pressure roll assembly.

Reinstall top cover and canister cover.

Tools Needed:

9

1

2

10

3

4

5

6

7

8

11

Loading...

Loading...