. A complete Parts List is available at www.MillerWelds.com

OM-283935 Page 31

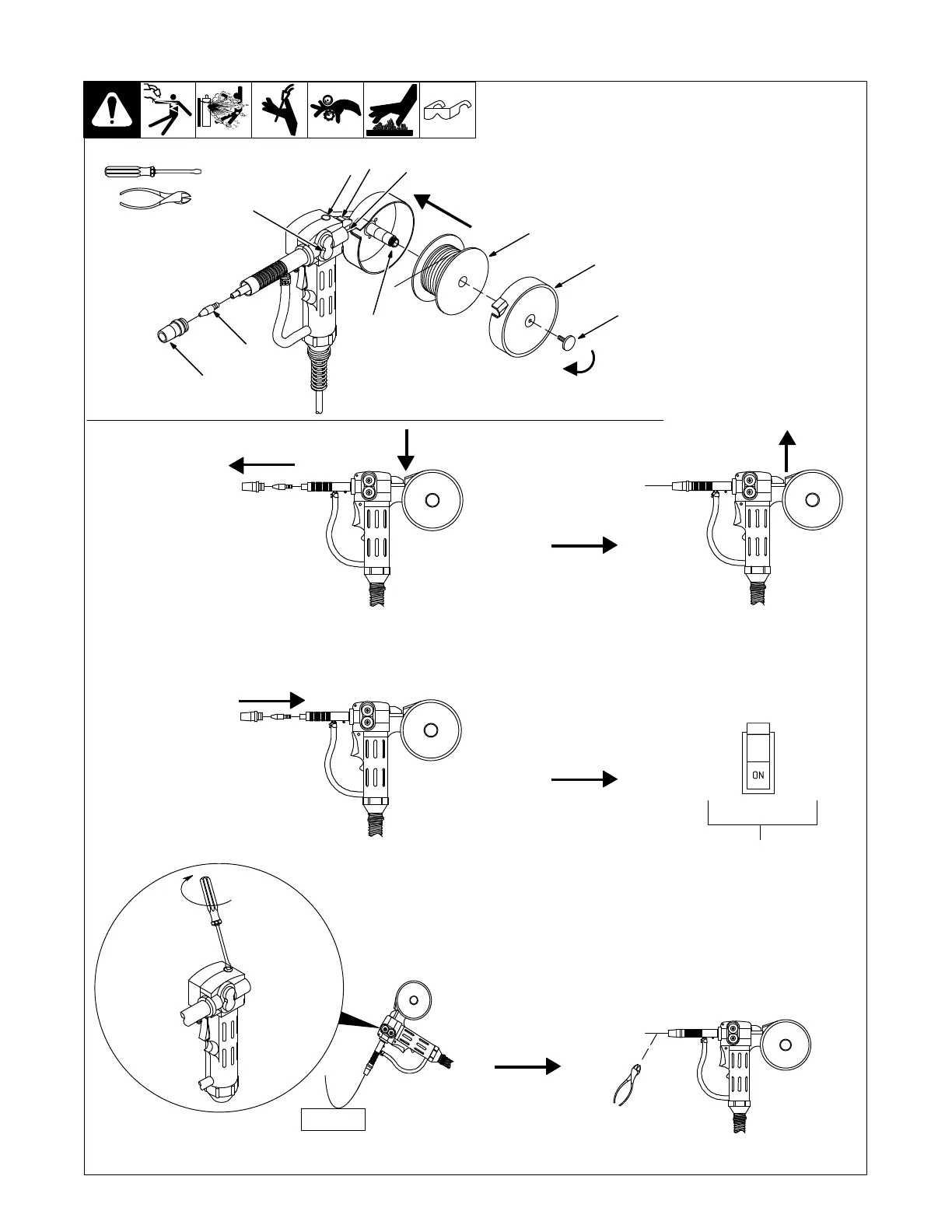

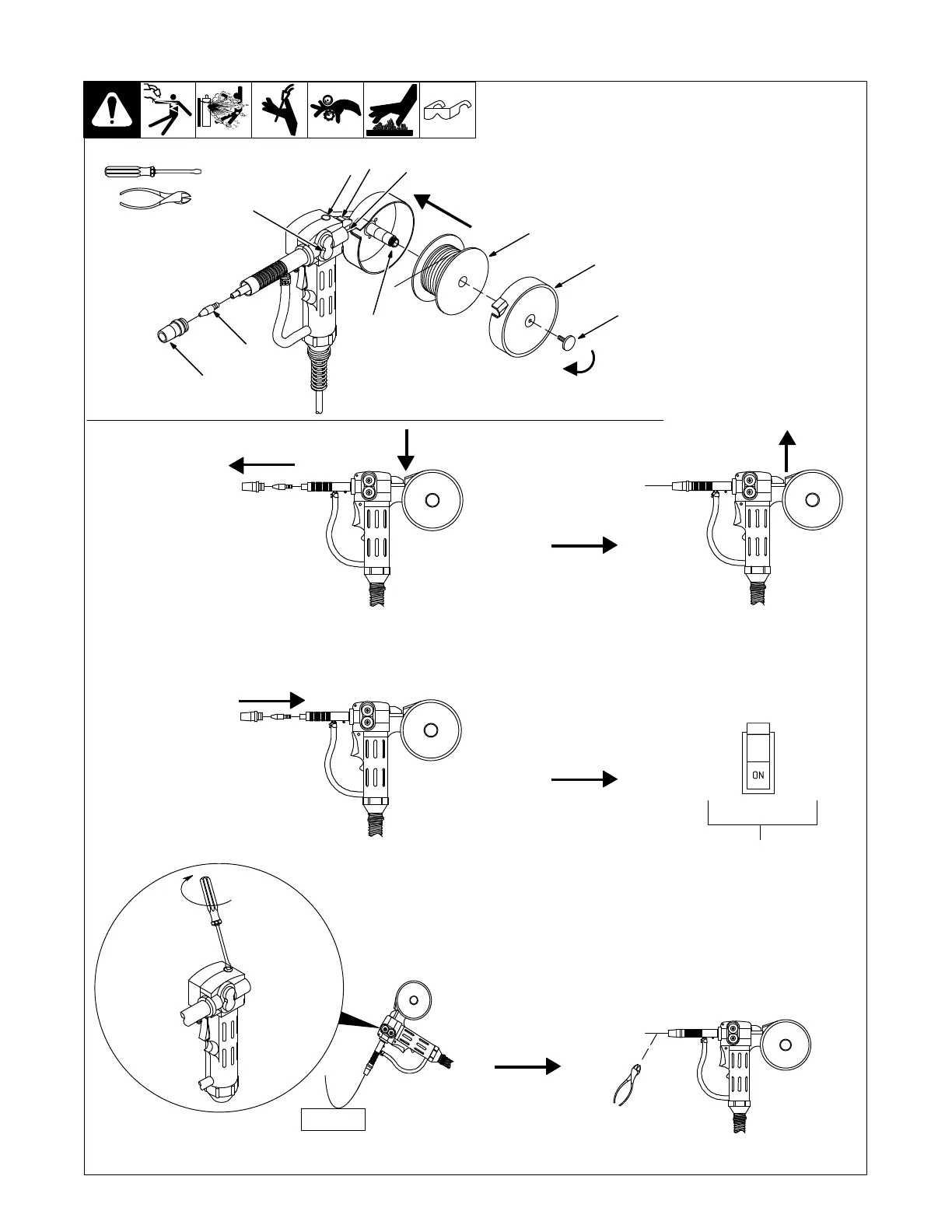

5-18. Installing Wire Spool And Threading Welding Wire For Spoolmate 100/150

804 985-A

Tools Needed:

1 Thumb Screw

2 Spool Cover

Remove thumb screw and spool

cover.

3 Spool Brake Thumbnut

4 Wire Spool

Install spool so wire feeds from top.

Turn spool brake thumbnut just so

a slight drag is felt on the wire spool.

5 Push Roll/Lower Drive Roll

6 Drive Roll Pressure

Adjustment Opening

7 Drive Roll Release Lever

(Red)

8 Wire Inlet Guide

9 Contact Tip

10 Nozzle

Remove nozzle and contact tip. Push

and hold red lever. Thread wire through

inlet guide, past push roll/drive roll, and

out end of gun 2 inches (50 mm).

Release red lever.

Turn On welding

power source power.

Install contact tip and nozzle. Reinstall

spool cover and thumb screw.

Wood

Cut off wire.

Press gun trigger to feed wire to check drive roll

pressure. Turn screw enough to prevent slipping.

. Drive roll pressure is preset for .030/.035

aluminum wire. Rotating screw clock-

wise decreases drive roll pressure

and counterclockwise increases

pressure.

4

1

5

6

7

8

10

9

3

2

Loading...

Loading...