OM-273245 Page 33

8-7. Profile Pulse

Profile Pulse optimizes Aluminum weld

bead appearance by producing welds with

consistently spaced ripple patterns, similar

to GTAW. This feature has been designed

to operate in a Synergic Pulsed MIG sys-

tem. The consistent ripple pattern is

achieved by periodically changing both the

wire feed speed and power level. The aver-

age wire feed speed is determined by the

value the unit is set to for welding.

. By default, Profile Pulse parameters

are hidden from the Setup Menu. To

view the parameters, the (PROF) set-

ting in the Setup Menu Level 2 must be

set to (YES). See section 8-2.

Profile Pulse Items that can be adjusted in

the Setup Menu are:

Profile Pulse ON/OFF (PROF) − Allows

Profile Pulse to be turned on or off.

Profile Pulse Frequency (P.FRQ) − Sets

the spacing between ripples in the weld

bead. Range of this setting is from (0.1 to

5.0) pulses per second. See Figures 1 and

2 below.

Profile Pulse Wire Feed Speed Change

(P.WFS) − Sets the percentage of change

above and below the wire feed speed the

unit is set to for welding. Range of this set-

ting is (X0.00 to X0.30). Example: If the wire

feed speed is 200 and (P.WFS) is set to

(X0.10), the wire feed speed will alternate

between 180 and 220 ipm.

Profile Pulse Arc Length (P.AL) − Sets an

arc length correction factor for the lower

wire feed speed. This setting is a percent-

age of the arc length the unit is set to for

welding. Range of this setting is from (X0.5

to X1.5). Example: If the arc length for weld-

ing is set to 50 and (P.AL) is set to (X1.1),

the arc length setting for the lower wire feed

speed is 55.

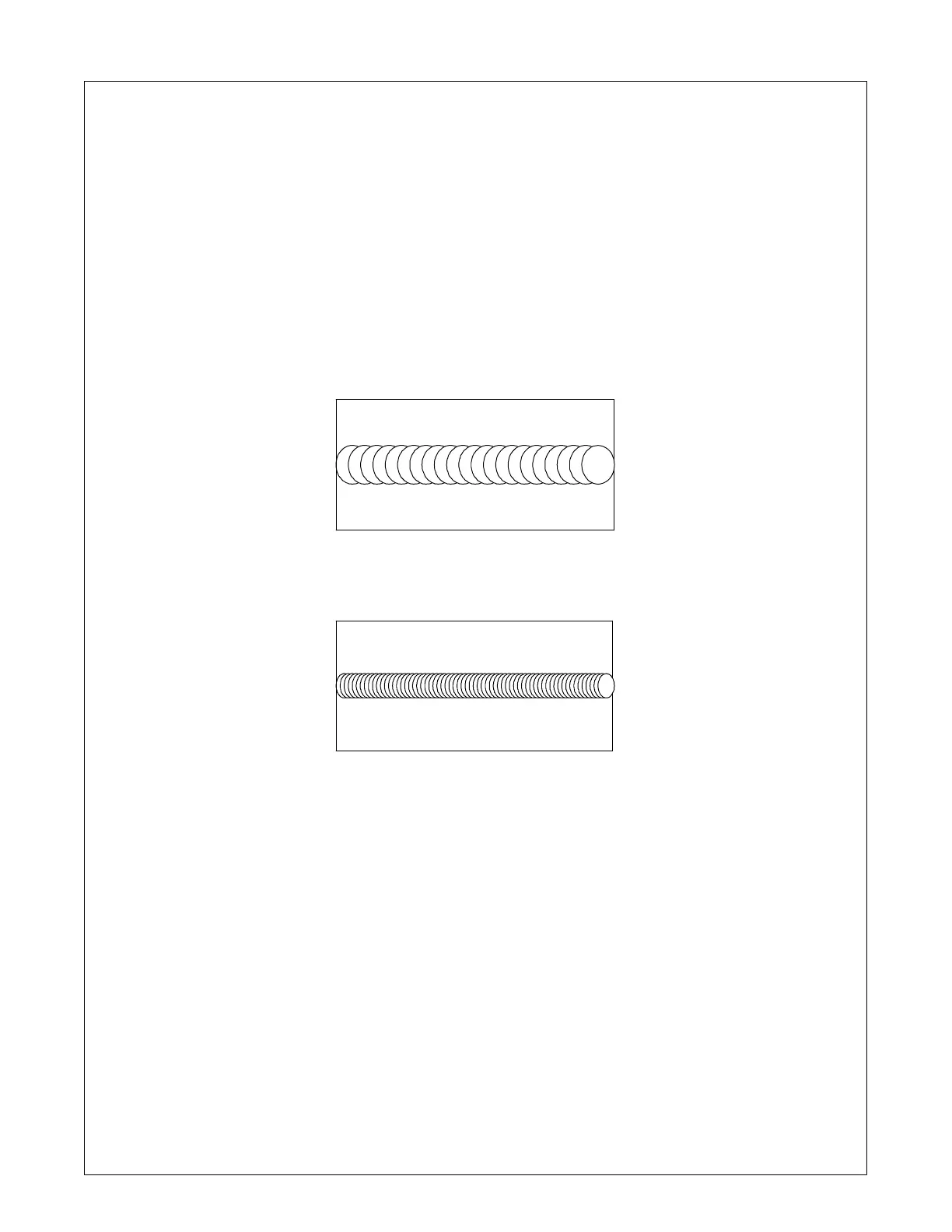

Figure 1

Constant travel speed with P.FRQ set to 0.1

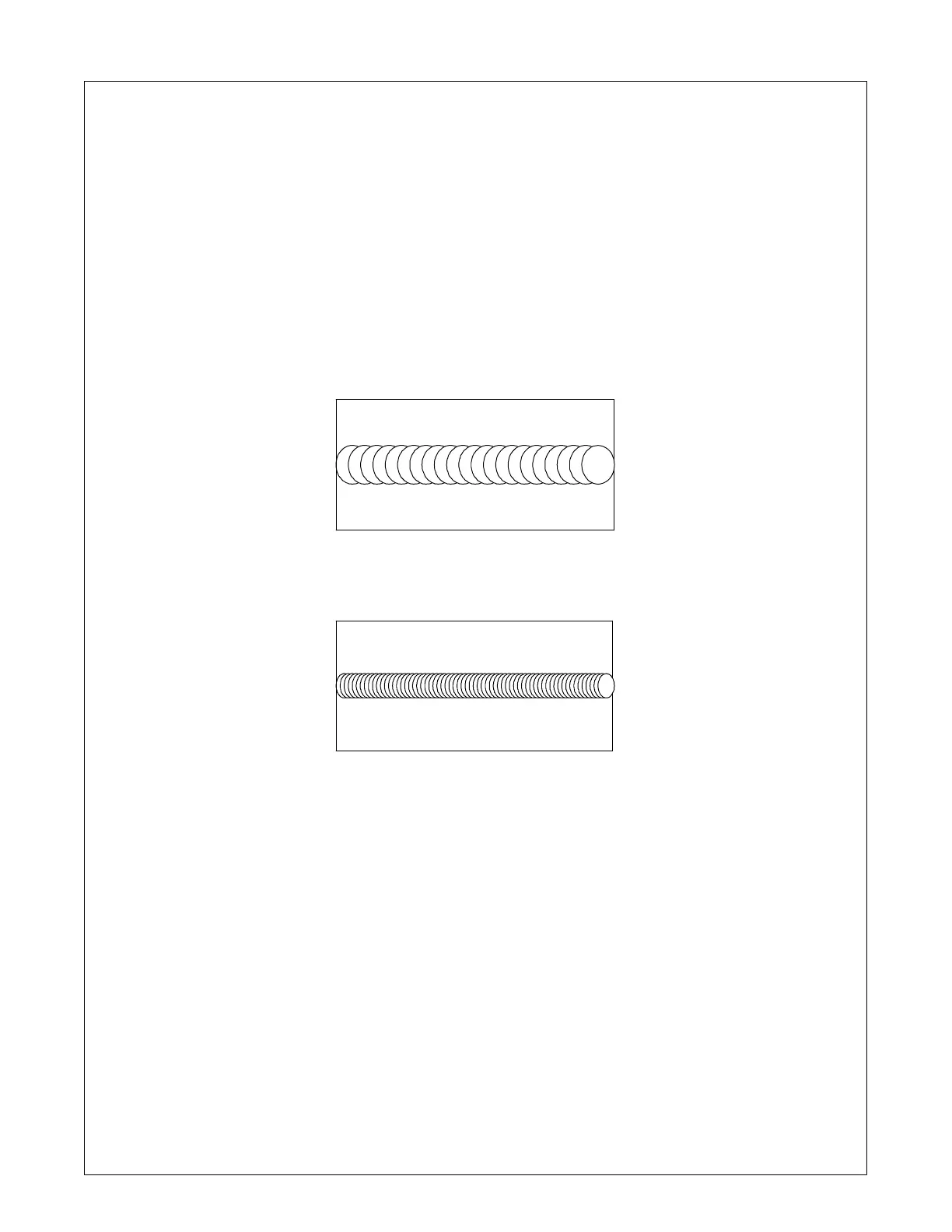

Figure 2

Constant travel speed with P.FRQ set to 5.0

Loading...

Loading...