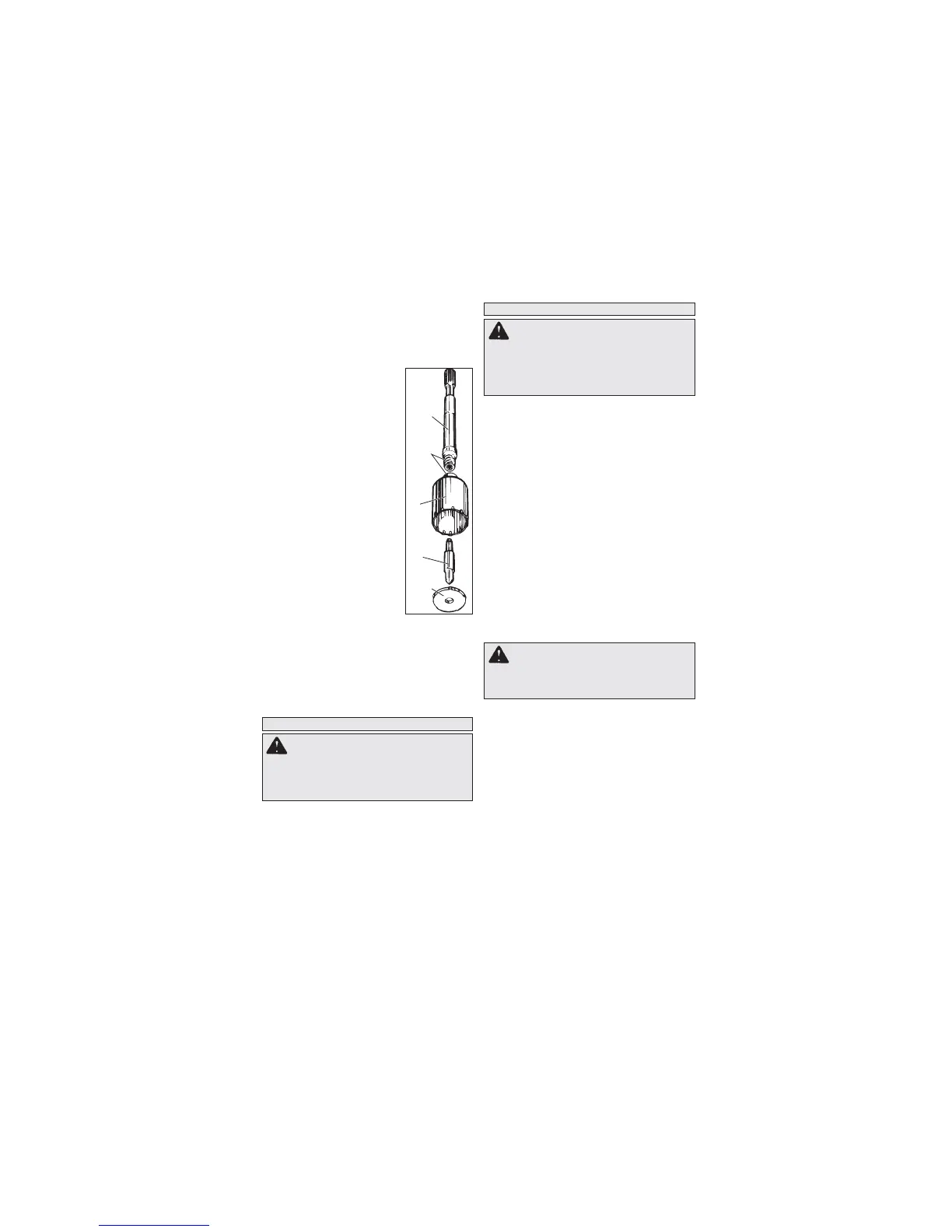

Adapter

Core

Bit

Center

Pin

Guide

Plate

Clean

and

lubricate

threads

Using Core Bits

Core bits are useful for drilling large holes for

conduit and pipe. MILWAUKEE Heavy-Duty Thin

Wall Core Bits have heat treated steel bodies with

durable carbide tips. They are specially designed

for fast, accurate drilling with combined hammering

and rotary action.

1. Clean and lubricate the threads

on the adapter and core bit as

indicated to make later removal

easier. Screw the threaded end

of the adapter into the rear of

the core bit.

2. Push the guide plate onto the

pointed end of the center pin.

Insert the center pin with guide

plate a ssembly into to the core

bit. Be sure the small end of the

center pin is securely placed

into the hole in the center of the

adapter.

3. Insert the adapter into the bit

holder of the tool as described

in “Inserting Drill Bit or Chisel”.

Set the rotary hammer/drill

lever to rotary hammer.

4. Press the center pin firmly

against your center mark, hold

the tool fi rmly and pull the trigger.

5. After drilling to about the depth

of the core bit teeth, remove the

center pin and guide plate from

the core bit. Resume drilling.

6. After you have fi nished drilling the hole, hold the

tool upwards, pointing it away from your body,

and run it briefl y in forward to loosen the core

bit from the adapter.

MILWAUKEE Heavy-Duty Thin Wall Core Bits drill

holes up to 3" deep. To make deeper holes, remove

the bit, break and remove the core. Resume drilling.

Maintaining Tools

Keep your tool in good repair by adopting a regular

maintenance program. Before use, examine the

general condition of your tool. Inspect guards,

switches, tool cord set and extension cord for

damage. Check for loose screws, misalignment,

binding of moving parts, improper mounting, bro-

ken parts and any other condition that may affect

its safe operation. If abnormal noise or vibration

occurs, turn the tool off immediately and have the

problem corrected before further use. Do not use a

damaged tool. Tag damaged tools “DO NOT USE”

until repaired (see “Repairs”).

Under normal conditions, relubrication is not neces-

sary until the motor brushes need to be replaced.

After six months to one year, depending on use,

return your tool to the nearest MILWAUKEE service

facility for the following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears,

spindles, bearings, housing, etc.)

• Electrical inspection (switch, cord, armature, etc.)

• Testing to assure proper mechanical and electrical

operation

Cleaning

Clean dust and debris from vents. Keep the tool

handles clean, dry and free of oil or grease. Use

only mild soap and a damp cloth to clean your tool

since certain cleaning agents and solvents are

harmful to plastics and other insulated parts. Some

of these include: gasoline, turpentine, lacquer thin-

ner, paint thinner, chlorinated cleaning solvents,

ammonia and household detergents containing

ammonia. Never use fl ammable or combustible

solvents around tools.

ACCESSORIES

WARNING To reduce the risk of injury,

always unplug the tool before attaching or

removing accessories. Use only specifi cally

recommended accessories. Others may be

hazardous.

WARNING To reduce the risk of injury,

electric shock and damage to the tool, never

immerse your tool in liquid or allow a liquid

to fl ow inside the tool.

MAINTENANCE

WARNING To reduce the risk of injury,

always unplug your tool before performing

any maintenance. Never disassemble the tool

or try to do any rewiring on the tool’s electrical

system. Contact a MILWAUKEE service facility

for ALL repairs.

Rely only on high-grade power tools on our virtual shelves.

Loading...

Loading...