Electro-magnetic interference (EMI) and leakage currents

66

PRECAUTIONS FOR USE OF THE INVERTER

Data line filter

Data line filter is effective as an EMI countermeasure. Provide a data line filter for the detector cable, etc.

<Example> Data line filter: ZCAT3035-1330 (by TDK)

ESD-SR-250 (by NEC TOKIN)

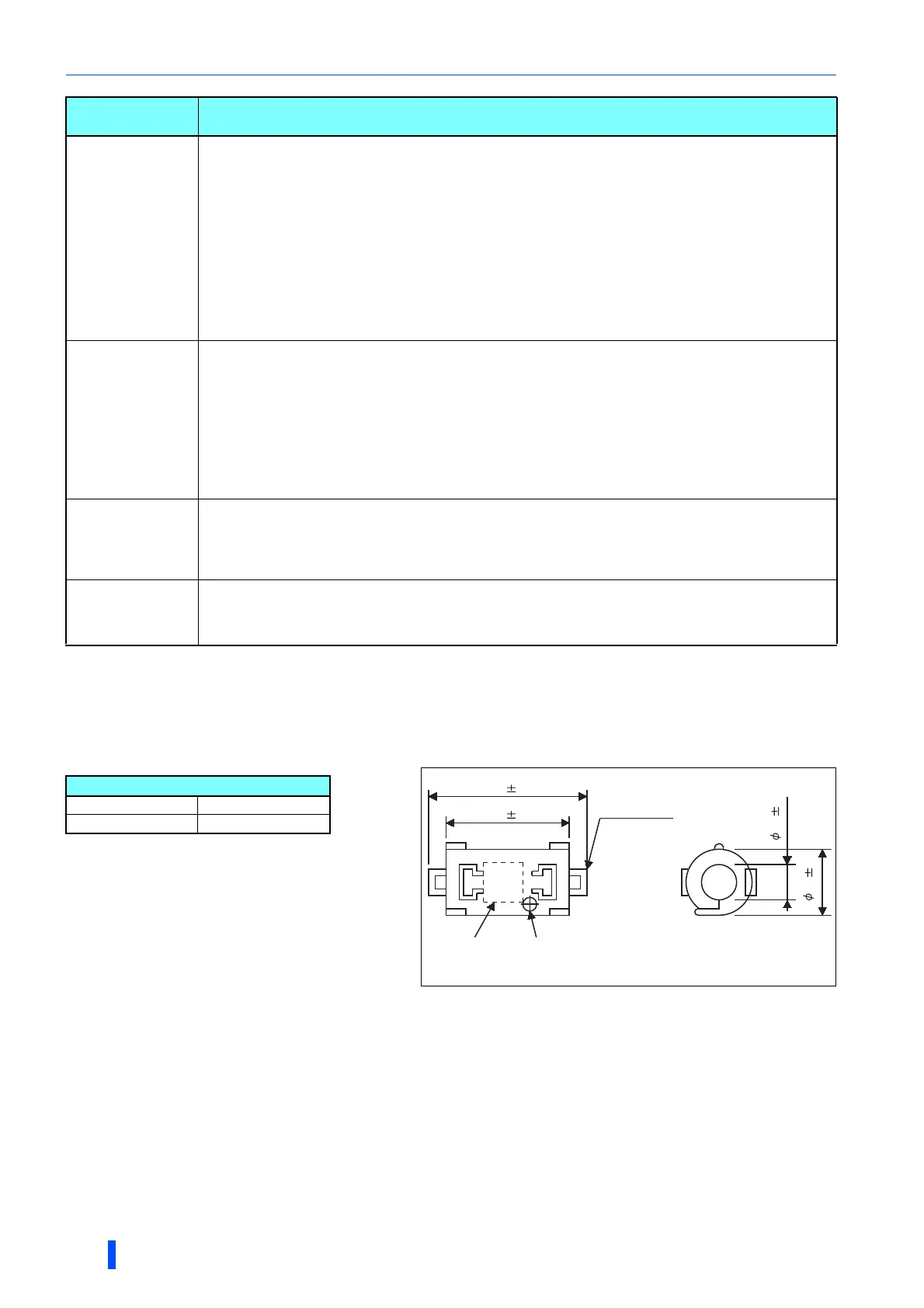

Impedance (ZCAT3035-1330)

The impedance values above are reference values, and not

guaranteed values.

Noise

propagation path

Countermeasure

(a)(b)(c)

When devices that handle low-level signals and are liable to malfunction due to electromagnetic noises, e.g.

instruments, receivers and sensors, are contained in the enclosure that contains the inverter or the converter unit,

or when their signal cables are run near the inverter, the devices may malfunction due to by air-propagated

electromagnetic noises. The following countermeasures must be taken:

• Install easily affected devices as far away as possible from the inverter or the converter unit.

• Run easily affected signal cables as far away as possible from the inverter or the converter unit, and its I/O

cables.

• Do not run the signal cables and power cables (inverter or converter unit I/O cables) in parallel with each other

and do not bundle them.

• Set the EMC filter ON/OFF connector of the converter unit to the ON position. (Refer to page 68.)

• Inserting a line noise filter into the output suppresses the radiated noise from the cables.

• Use shielded cables as signal cables and power cables and run them in individual metal conduits to produce

further effects.

(d)(e)(f)

When the signal cables are run in parallel with or bundled with the power cables, magnetic and static induction

noises may be propagated to the signal cables to cause malfunction of the devices and the following

countermeasures must be taken:

• Install easily affected devices as far away as possible from the inverter or the converter unit.

• Run easily affected signal cables as far away as possible from the inverter or the converter unit, and its I/O

cables.

• Do not run the signal cables and power cables (inverter or converter unit I/O cables) in parallel with each other

and do not bundle them.

• Use shielded cables as signal cables and power cables and run them in individual metal conduits to produce

further effects.

(g)

When the power supplies of the peripheral devices are connected to the power supply of the inverter or the

converter unit in the same line, its generated noises may flow back through the power supply cables to cause

malfunction of the devices and the following countermeasures must be taken:

• Set the EMC filter ON/OFF connector of the converter unit to the ON position. (Refer to page 68.)

• Install the line noise filter to the power cables (output cables) of the inverter.

(h)

When a closed loop circuit is formed by connecting the peripheral device wiring to the inverter or the converter unit,

leakage currents may flow through the earthing (grounding) cable of the inverter or the converter unit to cause the

device to malfunction. In that case, disconnecting the earthing (grounding) cable from the device may stop the

malfunction of the device.

Impedance ()

10 to 100 MHz 100 to 500 MHz

80 150

34 1

TDK

39 1

Product name Lot number

30 1

Cable fixing

band mount

13 1

OUTLINE DIMENSION DRAWINGS (ZCAT3035-1330)

[Unit: mm]