The Basics of Positioning Control Actuators for positioning

1 - 2

MITSUBISHI ELECTRIC

1.2 Actuators for positioning

The options available for positioning control depend on the type of actuator driving the system. An

actuator is a mechanical device that moves or controls a specific element or a series of elements within

a system.

In a mechanical system, an actuator is often used with a sensor to detect the motion or position of a

workpiece. The following illustrations provide examples of diversified actuators, their features and

their weak points.

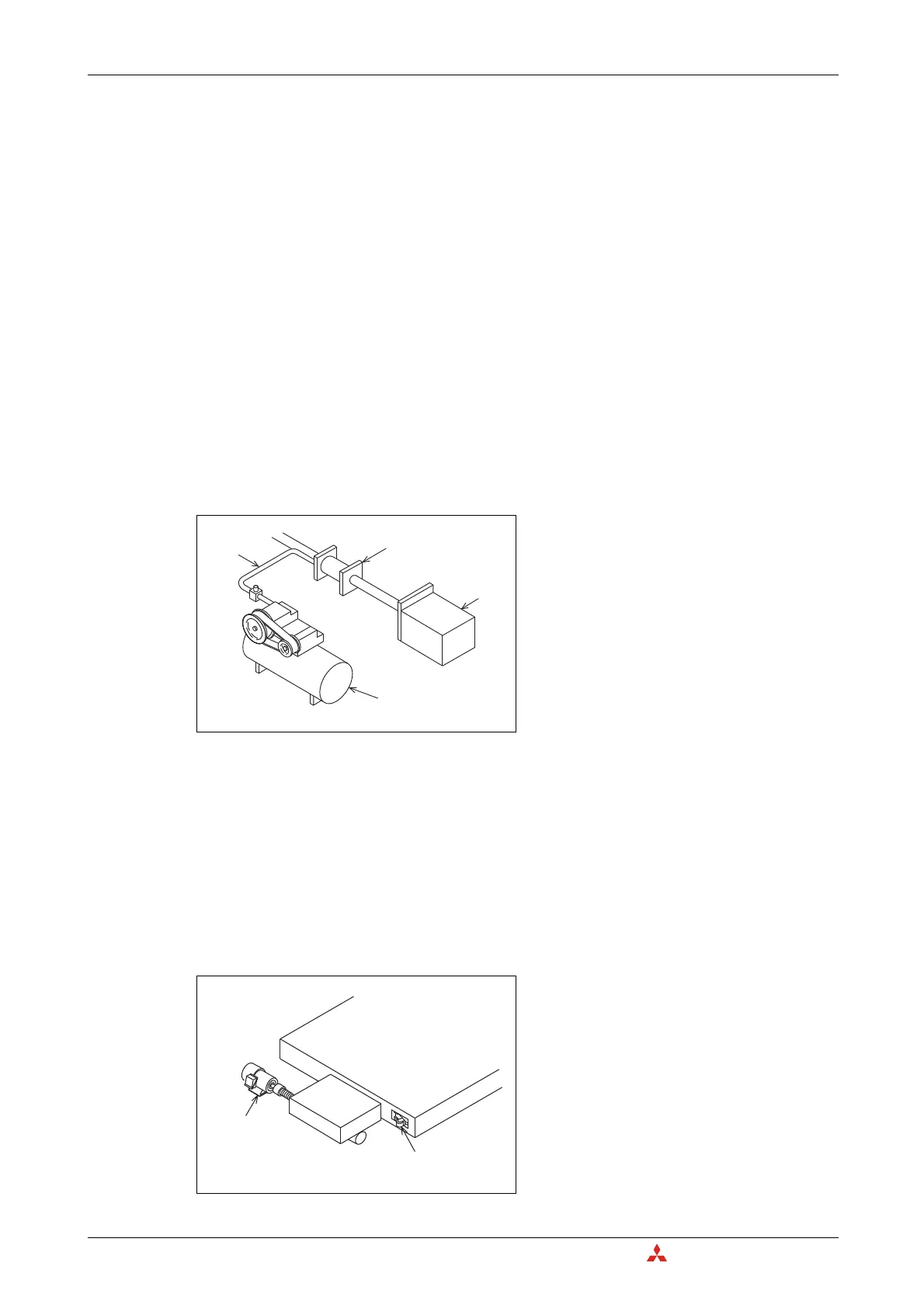

1.2.1 Pneumatic

Features and Drawbacks

● Air source and high grade piping are required.

● High torque is not available.

● Multi-point positioning is complex and very difficult to achieve.

● Change in positioning is difficult.

1.2.2 Brake motor

Features and Drawbacks

● Positioning mechanism is simple.

● Repeatability is poor.

● Change in positioning is difficult.

(When optical sensors or limit switches are used for stop)

Fig. 1-1:

Schematic drawing

Pneumatic

120010da.eps

Fig. 1-2:

Schematic drawing

Brake motor

120020da.eps

Air cylinder

Workpiece

Compressor

Piping

Limit switch

Motor with brake

Loading...

Loading...