11 - 22

MELSEC-A

11 MANUAL CONTROL

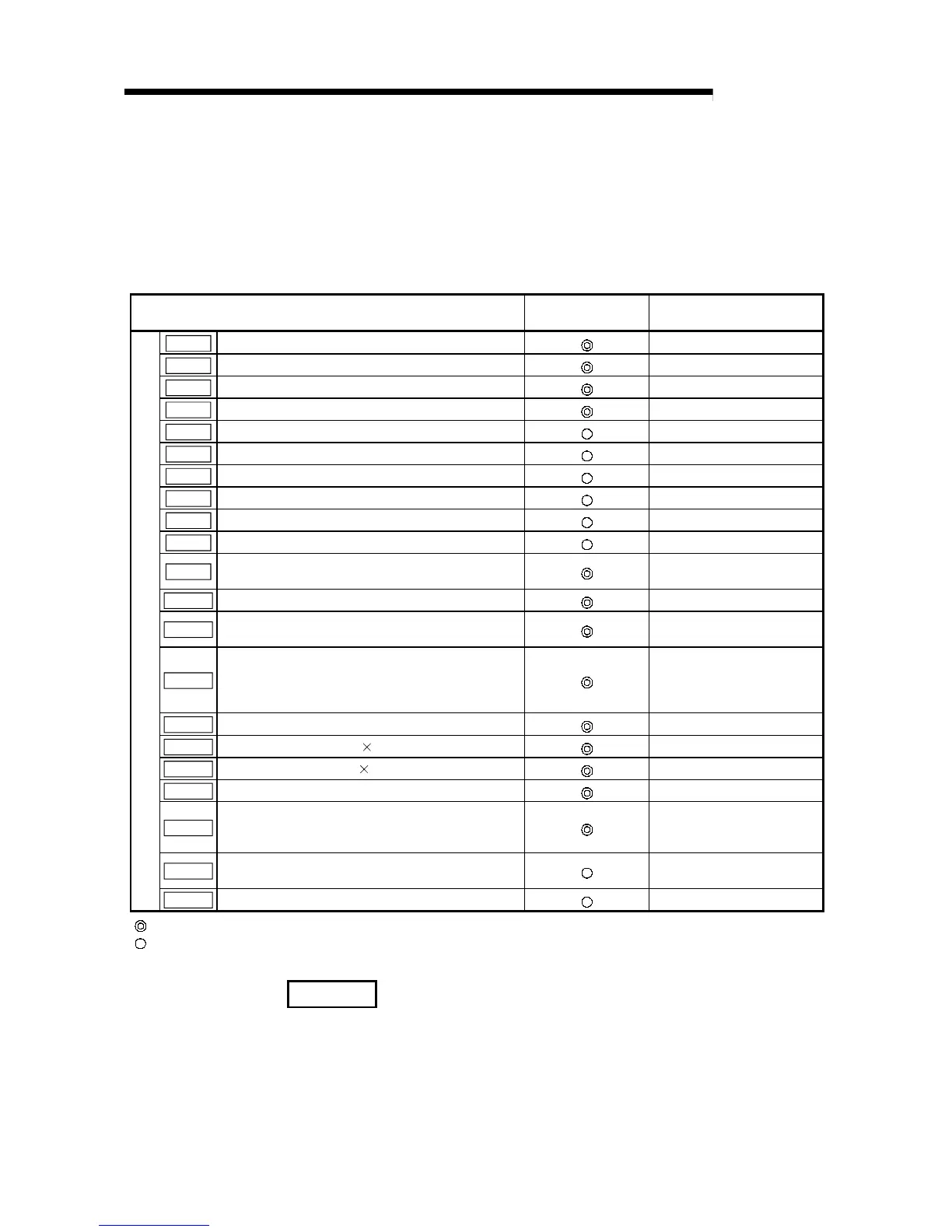

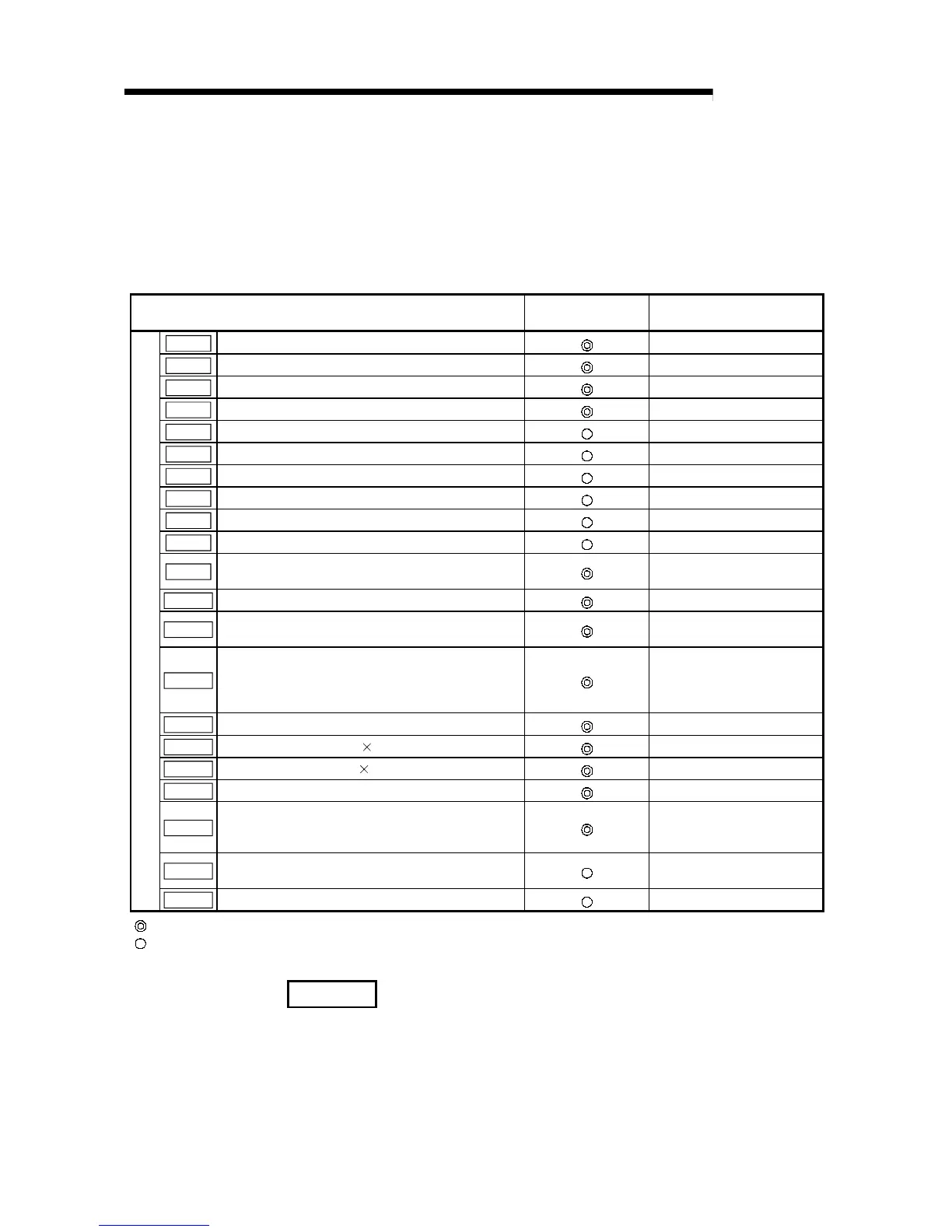

11.3.3 Setting the required parameters for manual pulse generator operation

The "Parameters" must be set to carry out manual pulse generator operation.

The following table shows the setting items of the required parameters for carrying out

manual pulse generator operation. When only manual pulse generator operation will

be carried out, no parameters other than those shown below need to be set. (Use the

initial values or setting values within a range where no error occurs for trouble-free

operation.)

Setting item Setting requirement

Factory-set initial value

(setting details)

Pr.1

Unit setting

3 (pulse)

Pr.2

No. of pulses per rotation (Ap) (Unit: pulse)

20000

Pr.3

Movement amount per rotation (Al) (Unit: pulse)

20000

Pr.4

Unit magnification (Am)

1 (1-fold)

Pr.12

Backlash compensation amount (Unit: pulse)

0

Pr.13

Software stroke limit upper limit value (Unit: pulse)

2147483647

Pr.14

Software stroke limit lower limit value (Unit: pulse)

–2147483648

Pr.15

Software stroke limit selection

0 (current feed value)

Pr.16

Software stroke limit valid/invalid setting

0 (invalid)

Pr.18

Torque limit setting value (Unit: pulse)

300

Pr.23

Manual pulse generator selection

Axis 1 = 1, axis 2 = 2,

axis 3 = 3

Pr.100

Servo series

0 (MR-H-B (MR-H-BN)

Pr.101

Amplifier setting

0 (Absolute position detection

invalid)

Pr.102

Regenerative brake resistor

0000

H

(External regenerative

brake option not used,

external dynamic brake

invalid)

Pr.103

Motor type

0 (HA-SH Standard)

Pr.104

Motor capacity (unit: kW

100)

0

Pr.105

Motor speed (unit: r/min

10

-3

)

1

Pr.106

Feedback pulse

0 (16384pulse)

Pr.107

Rotation direction

0 (Forward run with

positioning address

increment)

Pr.108

Auto tuning

1 (Auto tuning for ordinary

operation)

Parameters

Pr.109

Servo response setting

1 (Normal (low response))

: Setting always required.

: Set according to requirements (Leave set to the initial value when not used.)

REMARK

•

Parameter settings work in common for all control using the AD75. When carrying

out other control ("main positioning control", "advanced positioning control", "zero

point return positioning control"), the respective setting items must also be

matched and set.

•

Parameters are set for each axis.

•

Refer to "Chapter 5 DATA USED FOR POSITIONING CONTROL" for setting

details.

Loading...

Loading...