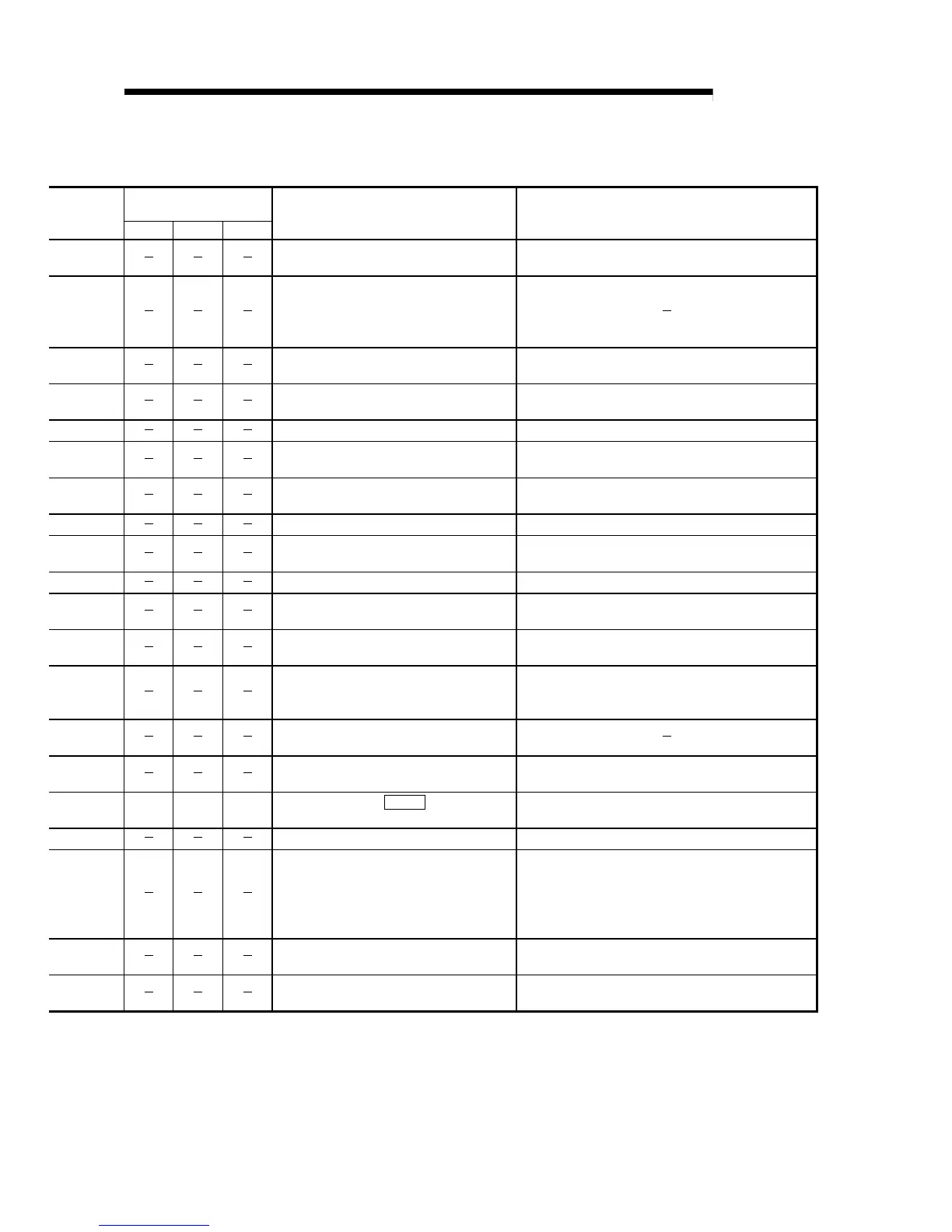

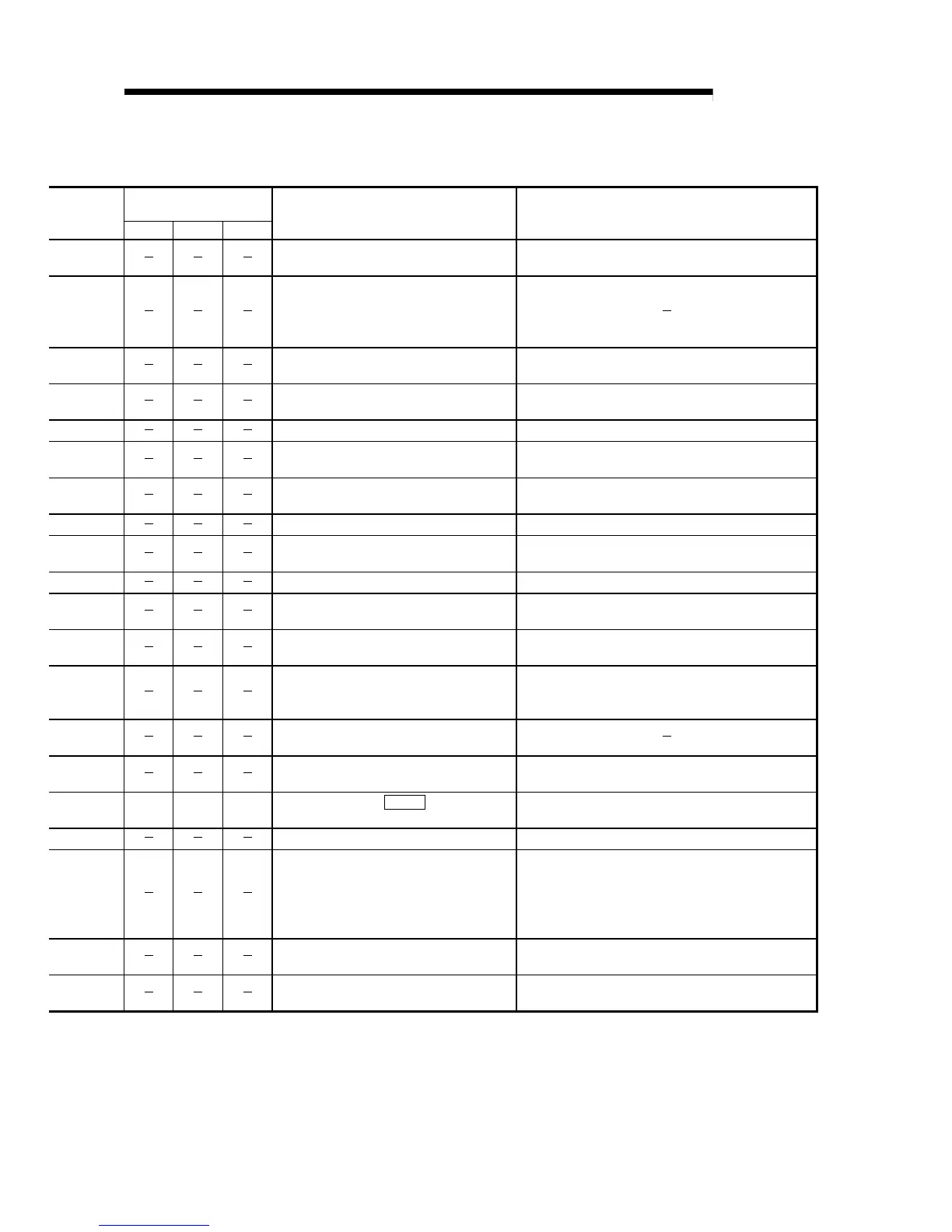

14 - 35

MELSEC-A

14 TROUBLESHOOTING

Relevant buffer memory

address

Axis 1 Axis 2 Axis 3

Checking method Remedy

Measure the input voltage (R, S, T) with a

voltmeter.

Review the power supply capacity.

Check if an instantaneous power failure

occurred.

Observe the input voltage with an

oscilloscope.

Measure the input voltage (R, S, T) with a

voltmeter.

Review the power supply capacity.

Change the unit. Change the unit.

Change the unit. Change the unit.

Change the unit. Change the unit.

Make visual check (to see if the connector is

disconnected or almost disconnected).

Connect correctly.

Change the servomotor. Change the servomotor.

Check the cable (change the cable).

Repair or change the cable (do not apply external force to

the cable).

Change the unit. Change the unit.

Check if the MC, etc. are operated at error

occurrence timing.

Take noise suppression measures.

Check the cable (change the cable).

Repair or change the cable (do not apply external force to

the cable).

Keep the power ON for a few minutes in the

error state and switch the power OFF, then

ON.

Keep the power ON for a few minutes to charge the super

capacitor, and switch the power OFF, then ON.

Perform initial setting of the zero point.

After switching the power OFF, measure the

voltage across the battery.

If the error still persists after the above

remedy.

Change the battery.

102 252 402

Check the setting of " Pr.102 Regenerative

brake resistor".

Set correctly.

Check the connection. Connect correctly.

1. Reconsider the regenerative brake torque

and the frequency of use of regenerative

braking.

2. Check the regenerative load factor in the

monitor mode.

1. Reduce the frequency of use of positioning.

2. Add the regenerative brake option.

3. Increase the servomotor capacity.

4. Reduce the load.

Check the resistance of the regenerative

power transistor using a tester.

Change the unit.

Check the resistance of the regenerative brake

resistor.

Change the regenerative brake resistor.

Loading...

Loading...