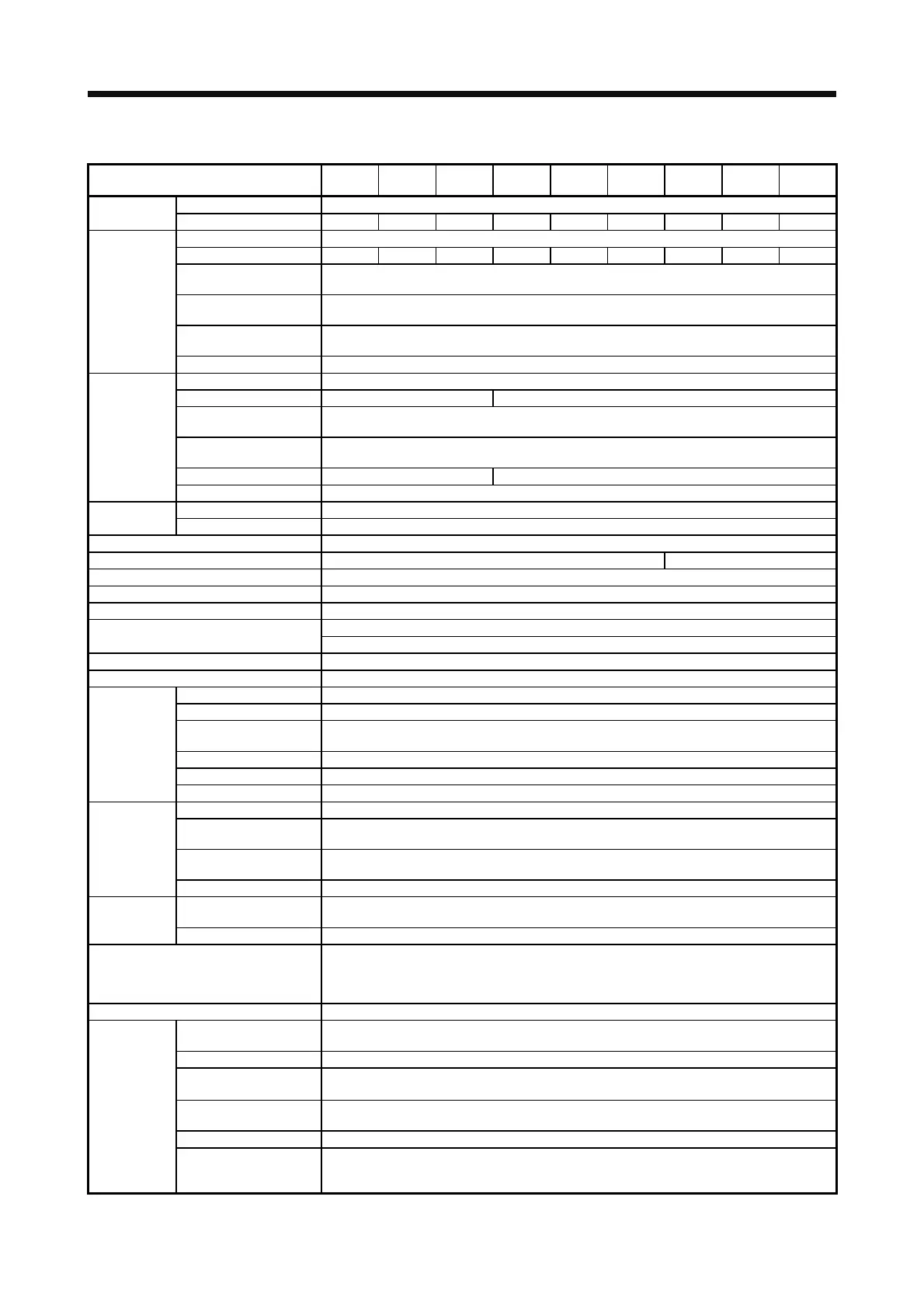

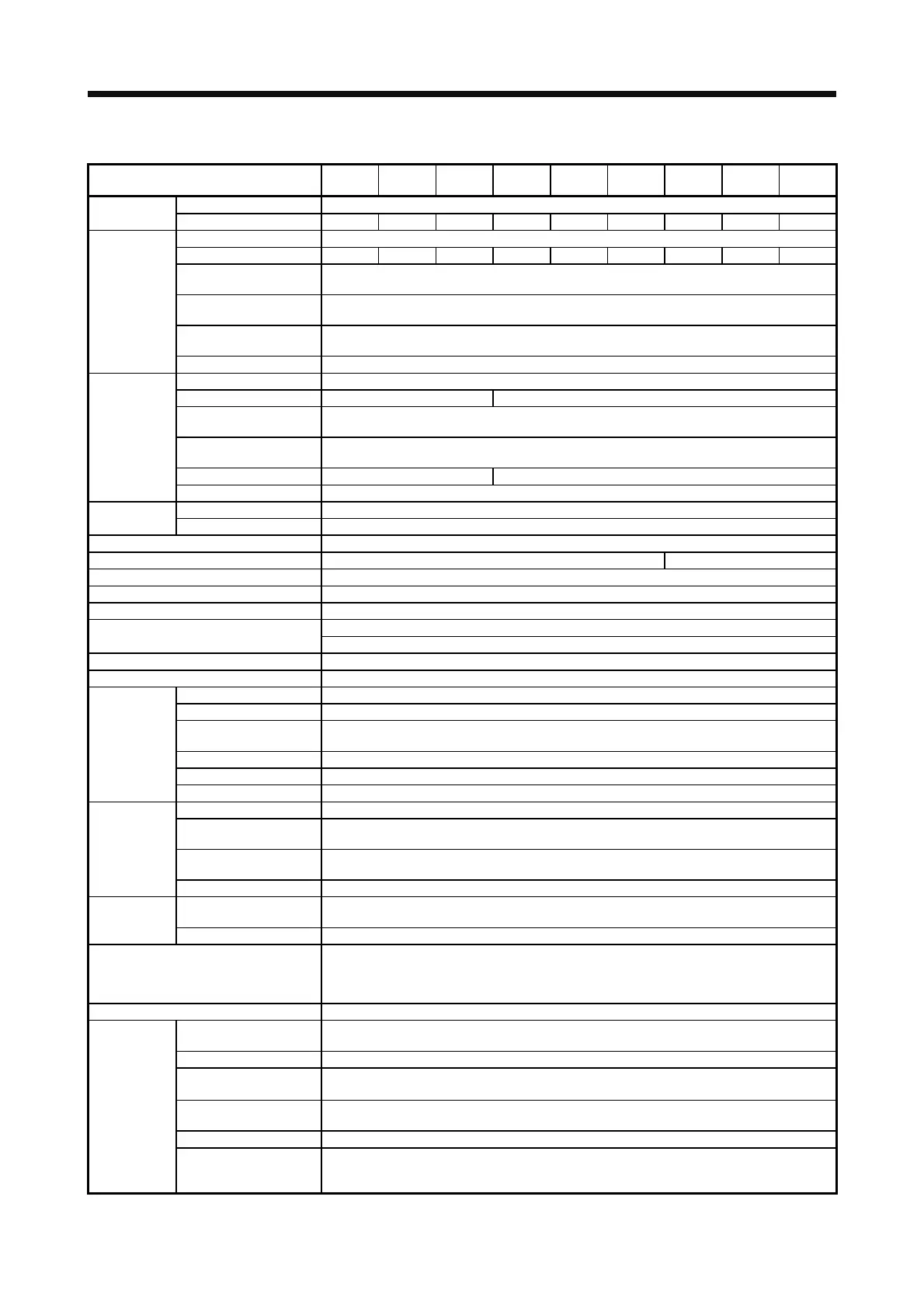

1. FUNCTIONS AND CONFIGURATION

1 - 11

(2) 400 V class

Model: MR-J4-

60A4

(-RJ)

100A4

(-RJ)

200A4

(-RJ)

350A4

(-RJ)

500A4

(-RJ)

700A4

(-RJ)

11KA4

(-RJ)

15KA4

(-RJ)

22KA4

(-RJ)

Rated voltage 3-phase 323 V AC

Output

Rated current [A] 1.5 2.8 5.4 8.6 14.0 17.0 32.0 41.0 63.0

Voltage/Frequency 3-phase 380 V AC to 480 V AC, 50 Hz/60 Hz

Rated current [A] 1.4 2.5 5.1 7.9 10.8 14.4 23.1 31.8 47.6

Permissible voltage

fluctuation

3-phase 323 V AC to 528 V AC

Permissible frequency

fluctuation

Within ±5%

Power supply

capacity

[kVA] Refer to section 10.2.

Main circuit

power supply

input

Inrush current [A] Refer to section 10.5.

Voltage/Frequency 1-phase 380 V AC to 480 V AC, 50 Hz/60 Hz

Rated current [A] 0.1 0.2

Permissible voltage

fluctuation

1-phase 323 V AC to 528 V AC

Control circuit

power supply

input

Permissible frequency

fluctuation

Within ±5%

Power consumption [W] 30 45

Inrush current [A] Refer to section 10.5.

Voltage 24 V DC ± 10%

Interface power

supply

Current capacity [A] (Note 1) 0.5 (including CN8 connector signals)

Control method Sine-wave PWM control, current control method

Dynamic brake Built-in External option (Note 6)

Fully closed loop control Compatible

Scale measurement function Not compatible

Load-side encoder interface (Note 5) Mitsubishi high-speed serial communication

USB: connection to a personal computer or others (MR Configurator2-compatible)

Communication function

RS-422: 1 : n communication (up to 32 axes)

Encoder output pulses Compatible (A/B/Z-phase pulse)

Analog monitor Two channels

Max. input pulse frequency 4 Mpulses/s (for differential receiver) (Note 4), 200 kpulses/s (for open collector)

Positioning feedback pulse Encoder resolution (resolution per servo motor revolution): 22 bits

Command pulse multiplying

factor

Electronic gear A:1 to 16777215, B:1 to 16777215, 1/10 < A/B < 4000

In-position range setting 0 pulse to ±65535 pulses (command pulse unit)

Error excessive ±3 revolutions

Position control

mode

Torque limit Set by parameter setting or external analog input (0 V DC to +10 V DC/maximum torque)

Speed control range Analog speed command 1: 2000, internal speed command 1: 5000

Analog speed command

input

0 to ±10 V DC/rated speed (The speed at 10 V is changeable with [Pr. PC12].)

Speed fluctuation ratio

±0.01% or less (load fluctuation 0 % to 100%), 0% (power fluctuation ±10%), ±0.2% or less (ambient

temperature 25 ± 10 °C) when using analog speed command

Speed control

mode

Torque limit Set by parameter setting or external analog input (0 V DC to +10 V DC/maximum torque)

Analog torque command

input

0 V DC to ±8 V DC/maximum torque (input impedance 10 kΩ to 12 kΩ )

Torque control

mode

Speed limit Set by parameter setting or external analog input (0 V DC to 10 V DC/rated speed)

Protective functions

Overcurrent shut-off, regenerative overvoltage shut-off, overload shut-off (electronic thermal), servo

motor overheat protection, encoder error protection, regenerative error protection, undervoltage

protection, instantaneous power failure protection, overspeed protection, error excessive protection,

magnetic pole detection protection, and linear servo control fault protection

Functional safety STO (IEC/EN 61800-5-2)

Standards certified by CB

EN ISO 13849-1 category 3 PL d, IEC 61508 SIL 2, EN 62061 SIL CL 2,

and EN 61800-5-2 SIL 2

Response performance 8 ms or less (STO input off → energy shut off)

(Note 2)

Test pulse input (STO)

Test pulse interval: 1 Hz to 25 Hz

Test pulse off time: Up to 1 ms

Mean time to dangerous

failure (MTTFd)

100 years or longer

Safety

performance

Diagnosis coverage (DC) Medium (90% to 99%)

Average probability of

dangerous failures per hour

(PFH)

1.68 × 10

-10

[1/h]

Loading...

Loading...