wheel enough to keep the tyre from wob-

bling.

l

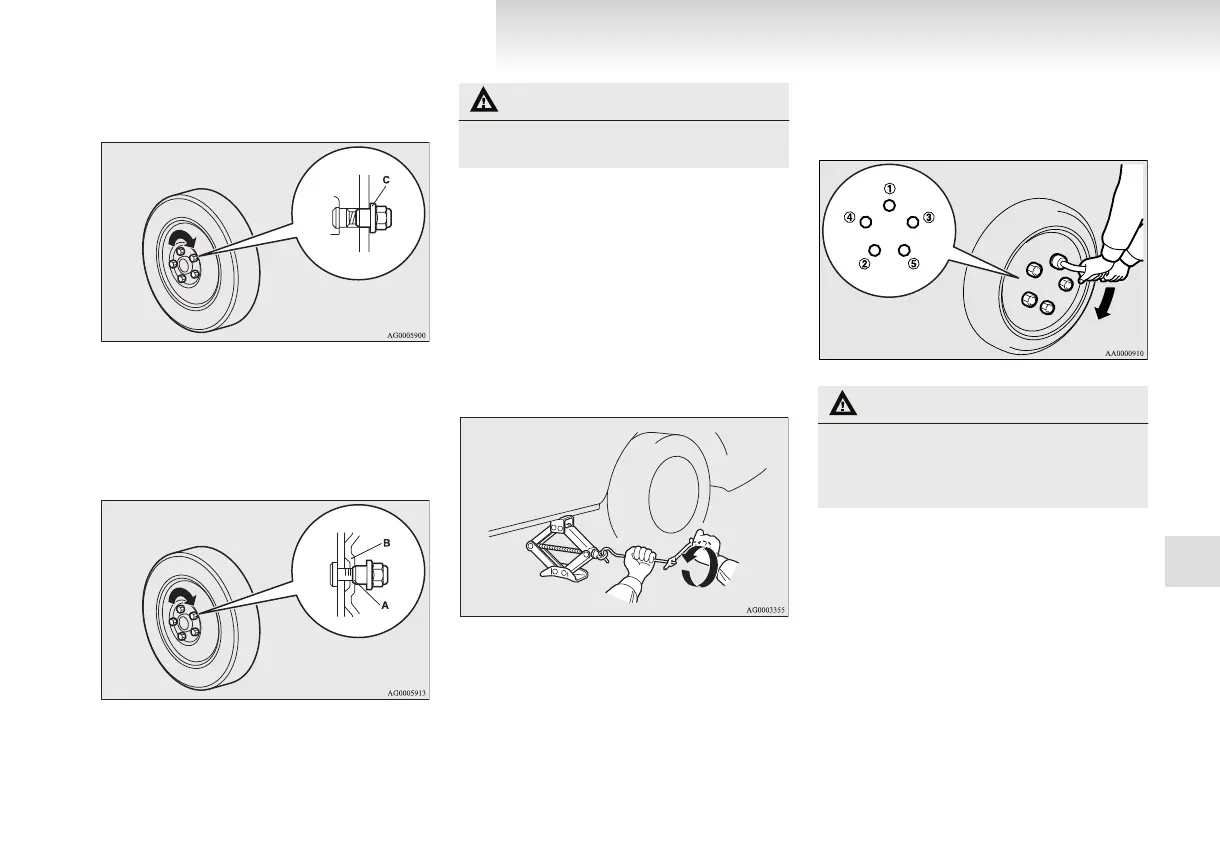

Steel spare wheel and temporary spare

wheel

Initially tighten the wheel nuts until the ta-

pered area (A) of the nuts lightly touches

the wheel hole seat area (B) enough to

keep the tyre from wobbling.

CAUTION

l

Never apply oil to either the wheel bolts

or the nuts, or they will tighten too much.

NOTE

l

Flange nuts can be temporarily used on the

steel wheel, but return to the original wheel

and tyre as soon as possible.

l

If all 4 aluminium wheels are changed to

steel wheels, e.g. when fitting winter tyres,

use tapered nuts.

8. Lower the vehicle slowly by rotating the

wheel nut wrench anticlockwise until the

tyre touches the ground.

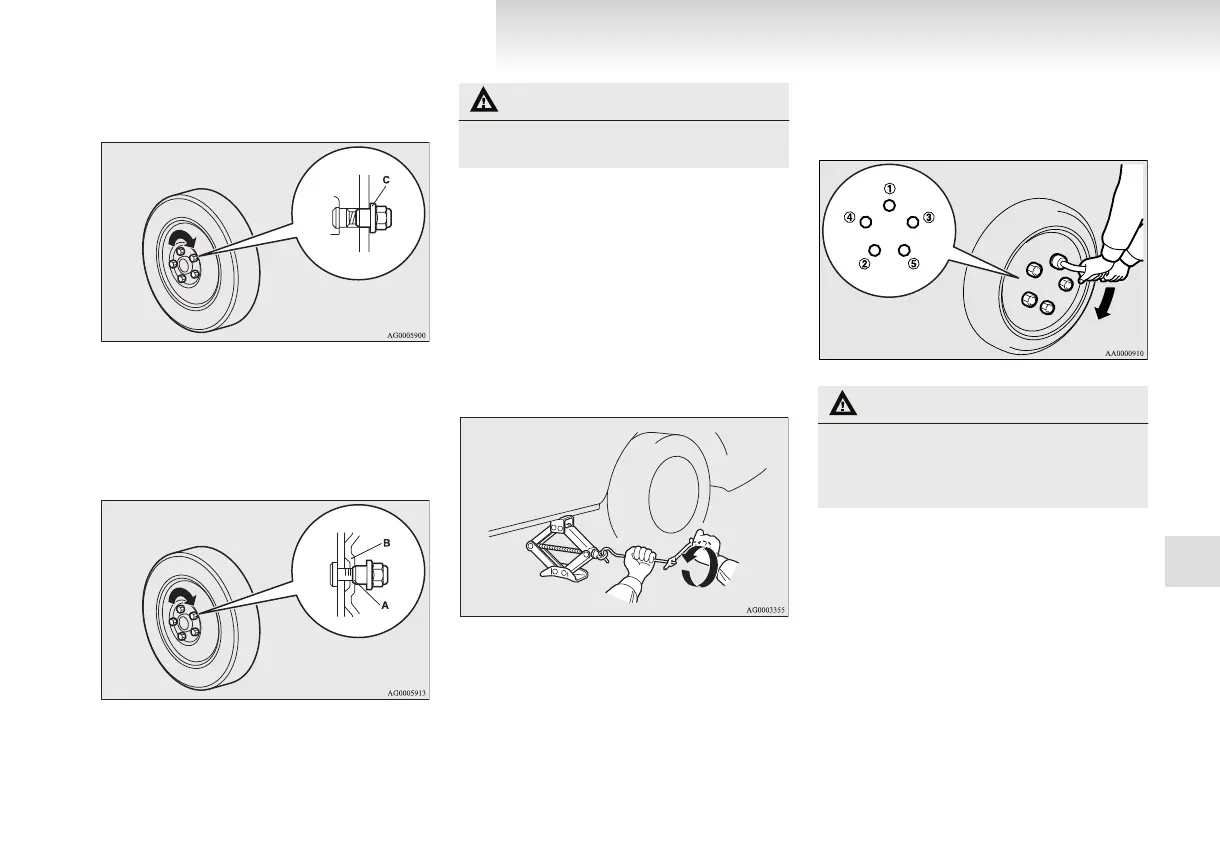

9. Tighten the nuts in the order shown in the il-

lustration until each nut has been tightened

to the torque listed here.

Tightening torque 88 to 108 Nm

(Achieved by applying force of 350 to 420 N

at end of wheel nut wrench supplied with ve-

hicle)

CAUTION

l

Never use your foot or a pipe extension

for extra force in the wheel nut wrench.

If you do so, you will tighten the nut too

much.

10. If the vehicle has a wheel cover, install it.

Refer to “Wheel covers” on page 6-18.

11. Lower and remove the jack, then store the

jack, flat tyre, and chocks. Have your dam-

aged tyre repaired as soon as possible.

12. Check your tyre inflation pressure at the next

gasstation. The correct tyre pressures are

shown on the driver’s door label. See the il-

lustration.

For emergencies

6-15

6

Loading...

Loading...