9-2

Chapter 9 Brakes

Torque specifications

Ft-lbs (unless otherwise indicated)

Brake caliper mounting bolts

S~liding caliper .......................................

51 to 65

Floating caliper

-Upper mounting bolt ................................

29 to 36

Lower mounting bolt

................................ 23 to 30

Caliper mounting bracket bolts

2WDmodels ........................................

51 to65

4WDmodels

........................................

58 to 72

Caliper inlet fitting .....................................

120 to 144 in-lbs

Disc-to-hub bolts

2WD ..............................................

36

4WD ..............................................

36to44 II

-.

Wheel cylinder mounting bolts

............................

13to15

Master cylinder mounting nuts

............................ 72 to 108.in-lbs

Power brake booster mounting nuts

....................... 72 to 108 in-lbs

Wheellugnuts ........................................

See Chapter I

1

General information

The vehicles covered by this manual are equipped with hydraulically

operated front and rear brake systems. The front brakes are disc-type.

Earlier models use a sliding caliper while later models use a floating cali-

per.

The rear brakes on all models are drum-type. Earlier models use a

duo-servo type rear brake while later models are equipped with leading/

trailing type.

These models are equipped with a dual master cylinder which allows

the operation of half of the system if the other half fails. This system also

incorporates a blend proportioning valve which limits pressure to the rear

brakes under heavy braking to prevent rear wheel lock-up. Later models

have a Load Sensing Proportioning Valve (LSPV) mounted to the frame

and connected to the rear axle by a link.

All models are equipped with a power brake boosterwhich utilizes en-

ginevacuum to assist in application of the brakes. The parking brakeoper-

ates the rear brakes only, through cable actuation.

There are some notes and cautions involving the brake system on this

vehicle:

a) Use only DOT 3 brake fluid in this system.

b) The brake pads and linings contain asbestos fibers which are haz-

ardous fo your health if inhaled. Whenever you work on the brake

system components, carefully clean all parts with brake cleaner.

Do not allow the fine asbestos dust to become airborne.

c) Safety should be paramount whenever any servicing of the brake

components is performed. Do not use parts or fasteners which are

not in perfect condition, and be sure that all clearances and torque

specifications are adhered to. If you are at all unsure about a certain

~~ procedge, seek professional advice. Upon completion of any

brake system work, test the brakes carefully in a controlled area be-

fore putting the vehicle into normal service. If a problem is sus-

~_ p~ected~in the brake system, do not drive the vehicle until the fault

is corrected.

d) Tires, load and front end alignment are factors which also affect

brakingperformance.

2 Disc brake pads - replacement

Warning: Disc brake pads must be replaced on both front wheels at the

s?ime tfme - never replace the pads on only one wheel. Also, the dust

created by the brake system may contain asbestos, whxh is harmful to

your health. Never blow it out with compressedairand don’t inhale any of

KAn approved filtering mask should be worn when working on the brakes.

Do not, under any circumstances, use petroleum-based solvents to clean

brake parts. Use brake cleaner or denatured alcohol on/y!

Note 1: When servicing the disc brakes, use only high-quality, nati&ally

recognized name brand pads.

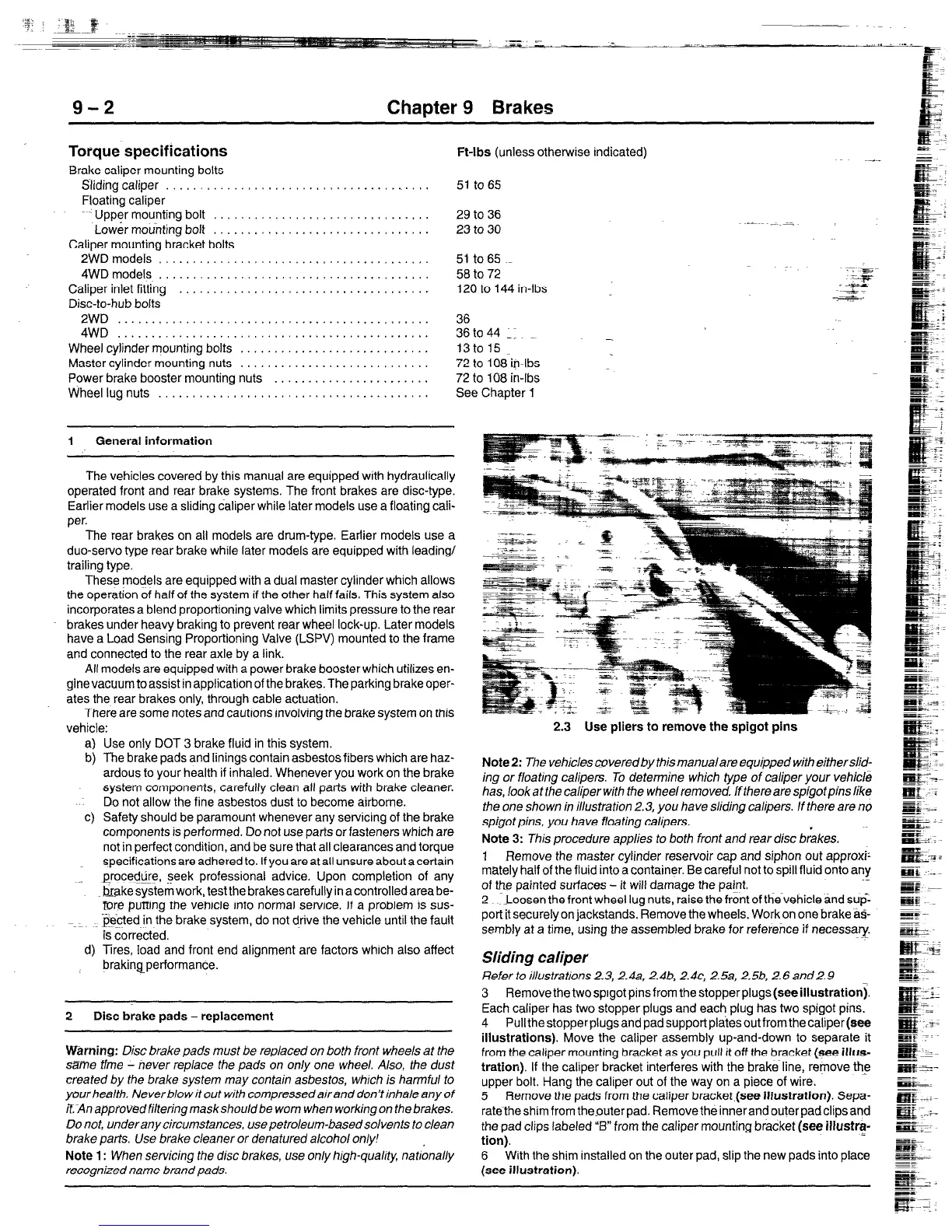

2.3 Use pliers to remove the spigot pins

Note 2: The vehicles covered by this manual are equipped with eitherslid-

ing or ffoating calipers. To determine which type of caliper your vehicle

has, look at the caliper with the wheel removed. Ifthere are spigofpins like

the one shown in illustration 2.3, you have sliding calipers. If there are no

spigot pins, you have floating calipers.

Note 3: This procedure applies to both front and rear disc brakes,

1 Remove the master cylinder reservoir cap and siphon out approxh

mately half of the fluid into a container. Be careful not to spill fluid onto any

of the painted surfaces - it will damage the paint,

.-

2 Loosen the front wheel lug nuts, raise the front of the vehicle and sup:

port it securely on jackstands. Remove the wheels. Work on

one brake tit?-

sembly at a time, using the assembled brake for reference if necessary.

Sliding caliper

fleferto illustrations2.3, 2.4a, 2.4b, 2.4~~ 2.5a, 2.5b, 2.6and2.9

3 Removethetwosplgotpinsfromthestopperplugs(seeillustration).

Each caliper has two stopper plugs and each plug has two sprgot pins.

4 Pullthestopperplugsandpadsupportpl~tesoutfromthecaliper(see

illustrations). Move the caliper assembly up-and-down to separate it

from the caliper mounting bracket as you pull it off the bracket (see illus-

tration). If the caliper bracket interferes with the brake~line, remove the

upper bolt. Hang the caliper out of the way on a piece of wire.

5 Remove the pads from the caliper bracket (see illustration). Sepa-

ratetheshimfromthesuterpad. Removetheinnerandouterpadclipsand

the pad clips labeled “5” from the caliper mounting bracket (see illustrf-

tion).

6 With the shim installed on the outer pad, slip the new pads into place

(see illustration).

Loading...

Loading...