6.- 18 Chader 6

Emissions control systems

11.1

~~ FY

l---J

3 J

H

,T?TEzL czs===-

automatic transmrrsron

Primary throttle valve

Nipple 7’ Vacuum delay

Secondary throttle valve

valve assembly

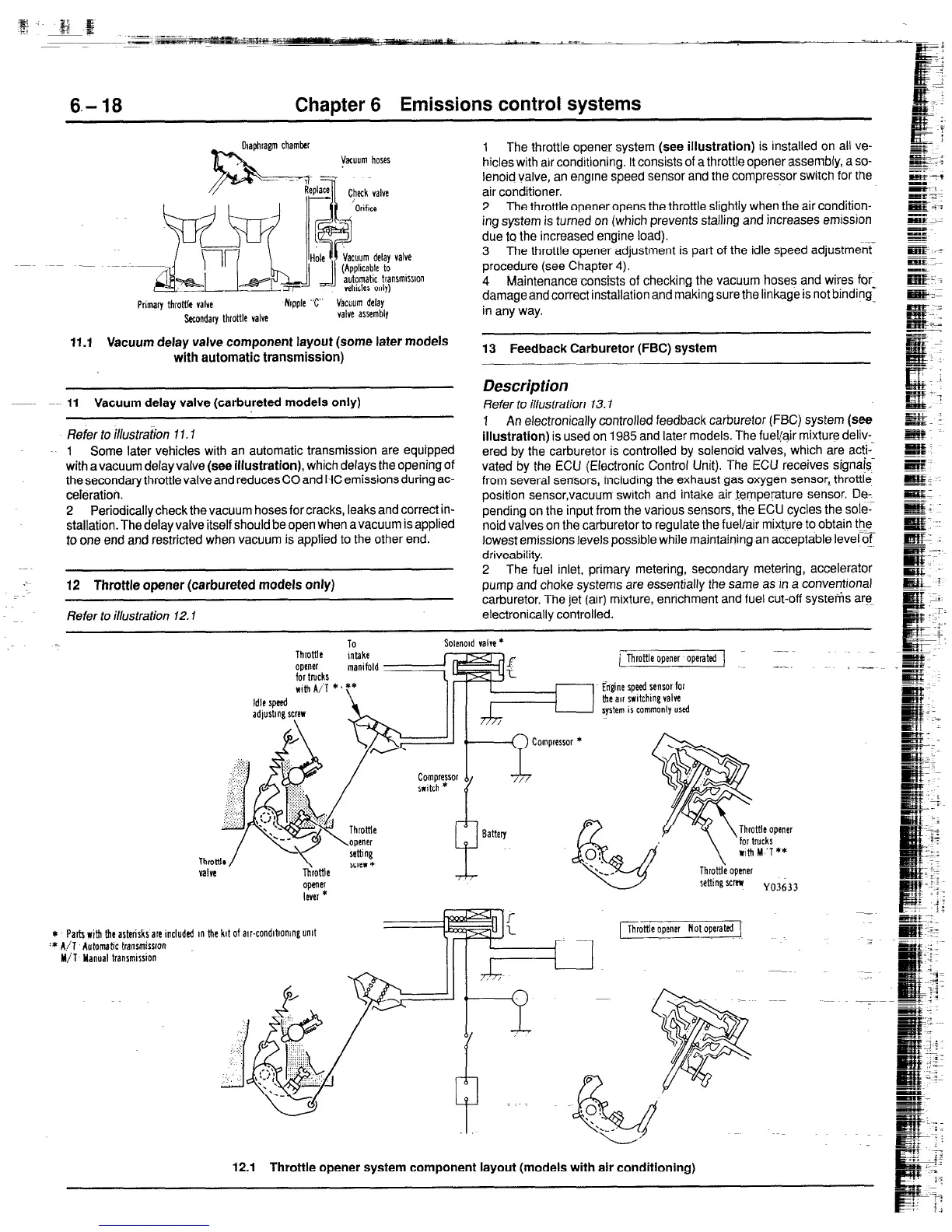

Vacuum delay valve component layout (some later models

with automatic transmission)

~~~~ 11 Vacuum delay valve (carbureted models only)

Refer fo illustration 11.7

1 Some later vehicles with an automatic transmission are equipped

with avacuum delay

valve (see illustration),

which delays the opening of

the secondary throttle valve and reduces CO and HC emissions during ac-

celeration.

2 Periodically check the vacuum hoses for cracks, leaks and correct in-

stallation. The delay valve itself should be open when avacuum is applied

to one end and restricted when vacuum is applied to the other end.

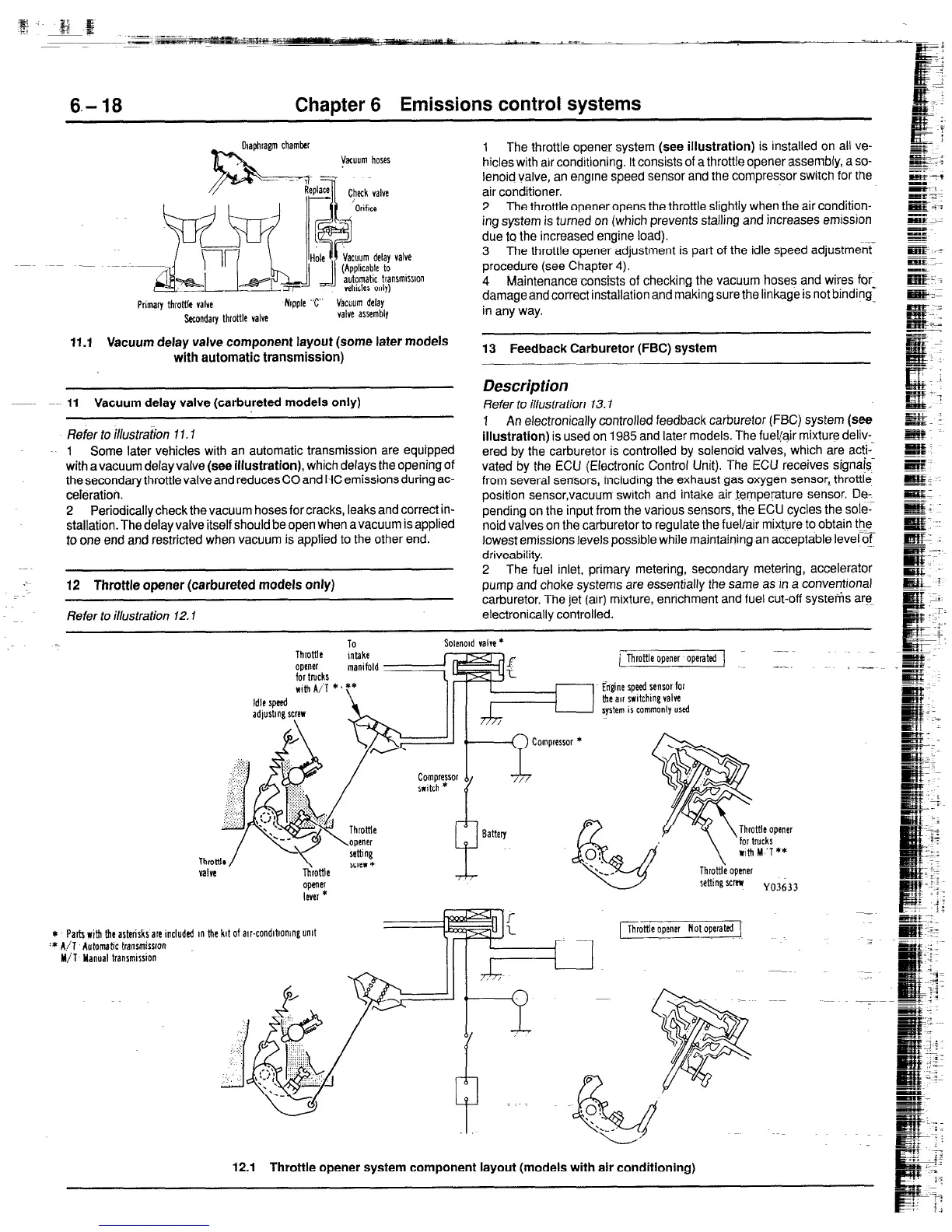

12 Throttle opener (carbureted models only)

Refer to illustration 12.1

1

The throttle opener system (see

illustration)

is installed on all ve-

hicles with arr conditioning. It consists of a throttle opener assembly, a so-

lenoid valve, an engine speed sensor and the compressor switch for the

air conditioner.

2

The throttle openeropens the throttle slightly when the air condition-

ing system is turned on (which prevents stalling and increases emission

due to the increased engine load).

3 The throttle opener adjustment is part of the idle speed adjustment

procedure (see Chapter 4).

4

Maintenance consists of checking the vacuum hoses and wires for,

damage and correct installation and making sure the linkage is not binding-

in any way.

13 Feedback Carburetor (FBC) system

Description

Refer to illustration 13.1

1

An electronically controlled feedback carburetor (FBC) system (see

illustration)

is used on 1985 and later models. The fuel@ir mixture deliv-

ered by the carburetor is controlled by solenoid valves, which are acti-

vated by the ECU (Electronic Control Unit). The ECU receives signajs-

from several sensors, including the exhaust gas oxygen sensor,. throttle

position sensor,vacuum swatch and intake air temperature sensor. De-

pending on the input from the various sensors, the ECU cycles the sole;

noid valves on the carburetor to regulate the fuel/air mixture to obtain the

lowest emissions levels possible while maintaining an acceptable level of.

driveability.

2

The fuel inlet, primary metering, secondary metering, accelerator

pump and choke systems are essentially the same as rn a conventronal

carburetor. The jet (air) mixture, enrichment and fuel cut-off systems are

electronically controlled.

FThrottle opener operated ~---

;1_

Engine speed sensor for

the au switching valve

system is commonly used

opener

lever *

* Par& with le asterisks are included rn the kit of arr-condrbomng unit

:* A/l Automatic trarrsmisrron

M/l Manual transmrrsion

-

1 Throttle opener Not operated (

12.1

Throttle opener system component layout (models with air conditlonlng)

Loading...

Loading...