5-12 Chapter 5 Engine electrical systems

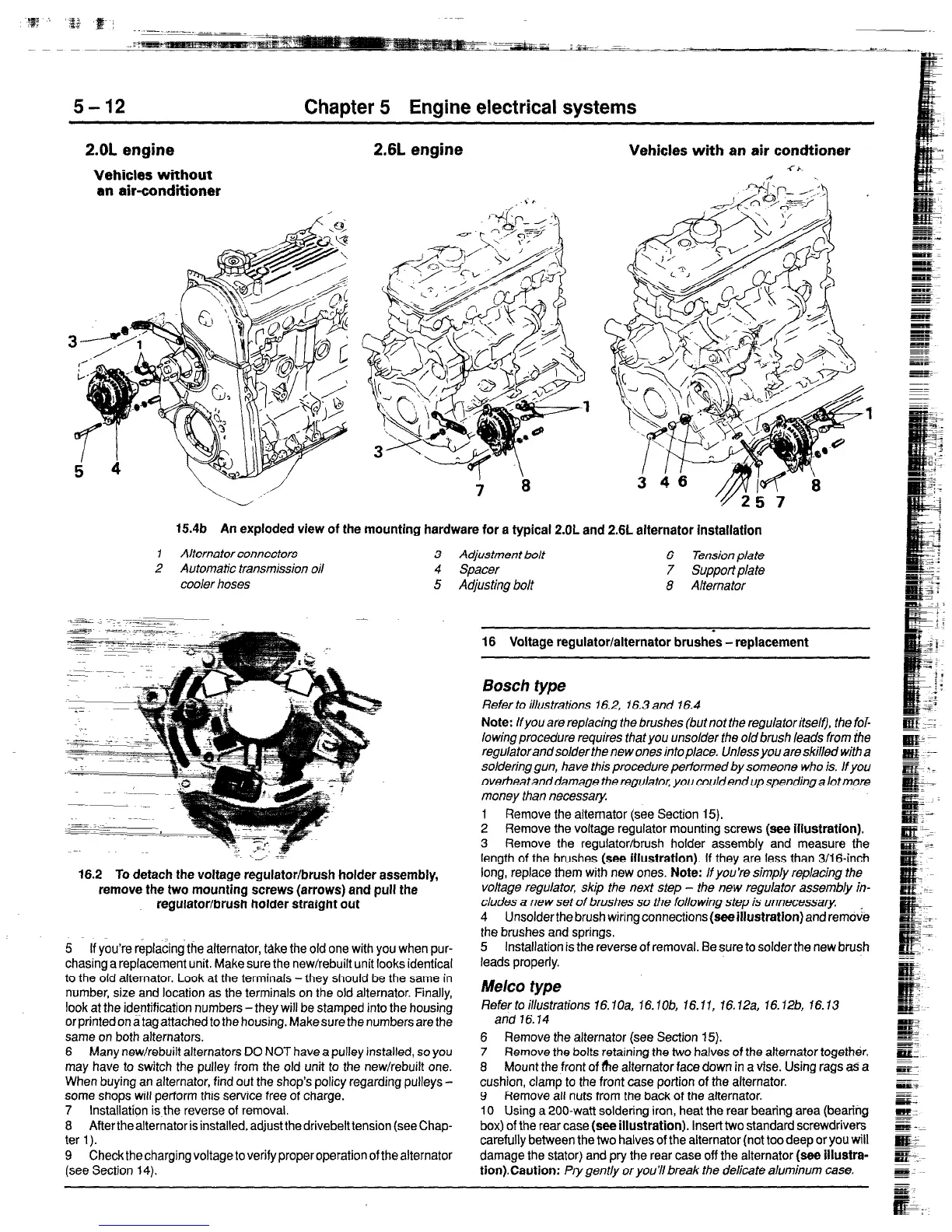

2.OL engine

Vehicles without

an air-conditioner

2.6L engine

Vehicles with an air condtioner

-CA

n

15.4b

An exploded view of the mounting hardware for a typical 2.OL and 2.6L alternator installation

1 Alternator connectors

3 Adjustment ho/t

6 Tension plate

2 Automatic transmission oil 4 Spacer

7

Support plate

cooler hoses 5 Adjusting bolt 8 Alternator

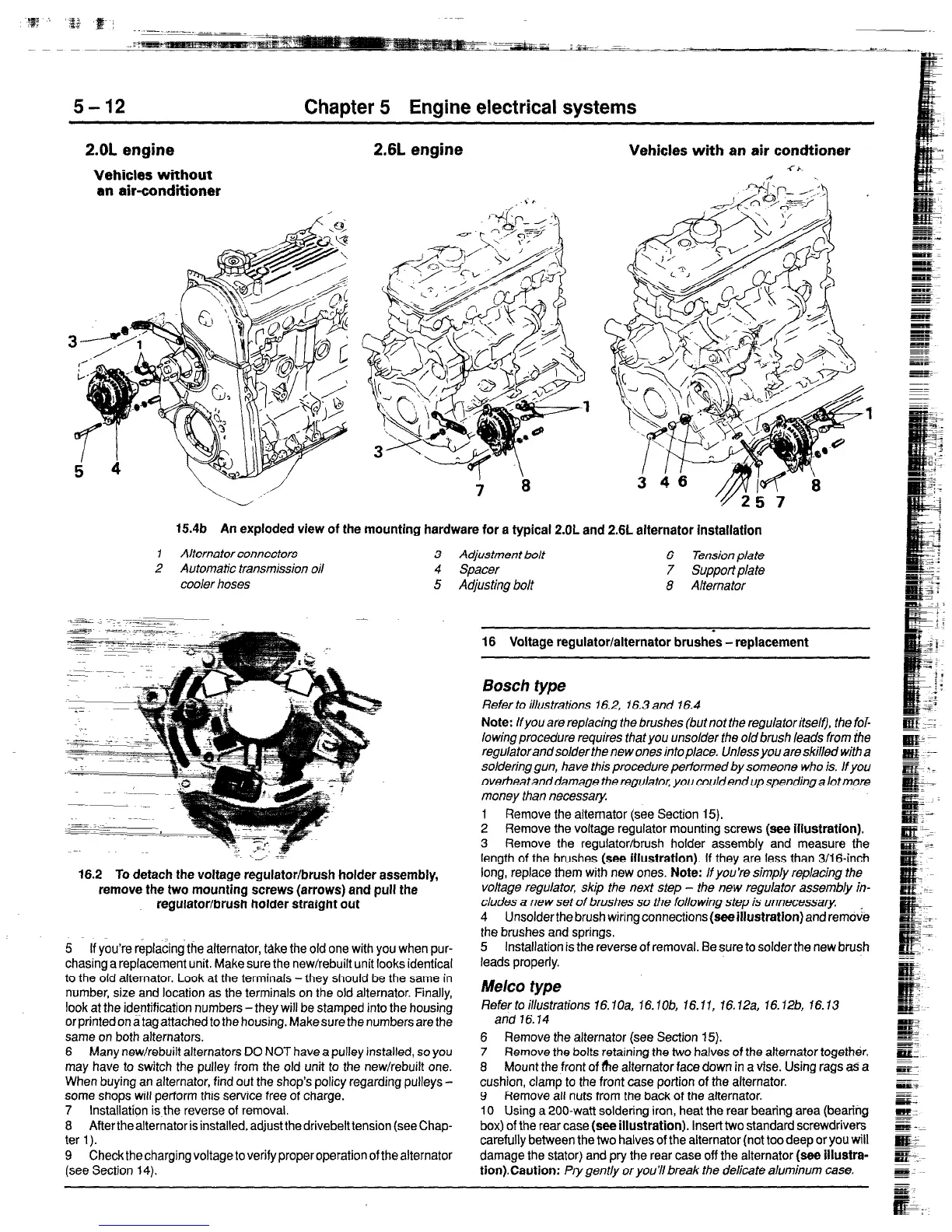

16.2

To detach the voltage regulator/brush holder assembly,

remove the two mounting screws (arrows) and pull the

regulator/brush holder straight out

5 If you’re replacing the alternator, take the old one with you when pur-

chasing a replacement unit. Make sure the new/rebuilt unit looks identical

to the old alternator. Look at the terminals -they should be the same in

number, size and location as the terminals on the old alternator. Finally,

look at the identification numbers -they will be stamped into the housing

or printed on atag

attached

to the housing. Make sure the numbers are the

same on both alternators.

6 Many new/rebuilt alternators DO NOT have a pulley installed, so you

may have to switch the pulley from the old unit to the new/rebuilt one.

When buying an alternator, find out the shop’s policy regarding pulleys -

come shops will perform this service free of charge.

7 Installation is the reverse of removal.

8 ARertheaiternatorisinstalled,adjustthedrivebelttension (seechap-

ter 1).

9 Check the charging voltage to verify proper operation of the alternator

(see Section 14).

1

16 Voltage regulator/alternator brushes - replacement

Bosch type

Refer to illustrations 16.2, 16.3 and 16.4

Note:

If you are replacing the brushes (but not the regulator itself), the fof-

lowing procedure requires that you unsolder the old brush leads from the

regulatorand solder the new ones into place.

Unless you are skrKvd with a

soldering gun, have this procedure performed by someone who is. If you

overheatanddamage theregulator, you couldendupspendinga lotmore

money than necessary

I Remove the alternator (see Section 15).

2 Remove the voltage regulator mounting screws (see illustration).

3

Remove the regulator/brush holder assembly and measure the

length of the brushes (see illustration). If they are less than 3/16-inch

long, replace them with new ones. Note:

lf you’re simpfy rep/acing the

voltage regulator, skip the next step - the new regulator assembly in-

cludes a new set of brushes so the following step is unnecessary

4

Unsolderthe brush wiringconnections(eeeillustration)andremove

the brushes and springs.

5

Installation is the reverse of removal. Be sure to solder the new brush

leads properly.

Melt20 type

Refertoitlustrations 16.1Oa, l&lob, 16.11, 16,12a, 76.12b, 16.13

and

16.14

6

Remove

the alternator (see Section 15).

7 Remove the bolts retaining the two halves of the alternator together.

8

Mount the front of fhe alternator face down in a vise. Using rags as a

cushion, clamp to the front case portion of the alternator.

9

Remove all nuts from the back of the alternator.

10 Using a 200-watt soldering iron, heat the rear bearing area (bearing

box) of the rear case (see illustration). Insert two standard screwdrivers

carefully between the two halves of the alternator (not too deep or you will

damage the stator) and pry the rear case off the alternator (see illustra-

tion).Caution:

Pry gent/y or you’ll break the

delicate

aluminum case.

Loading...

Loading...