4-6

Chapter 4 Fuel and exhaust systems

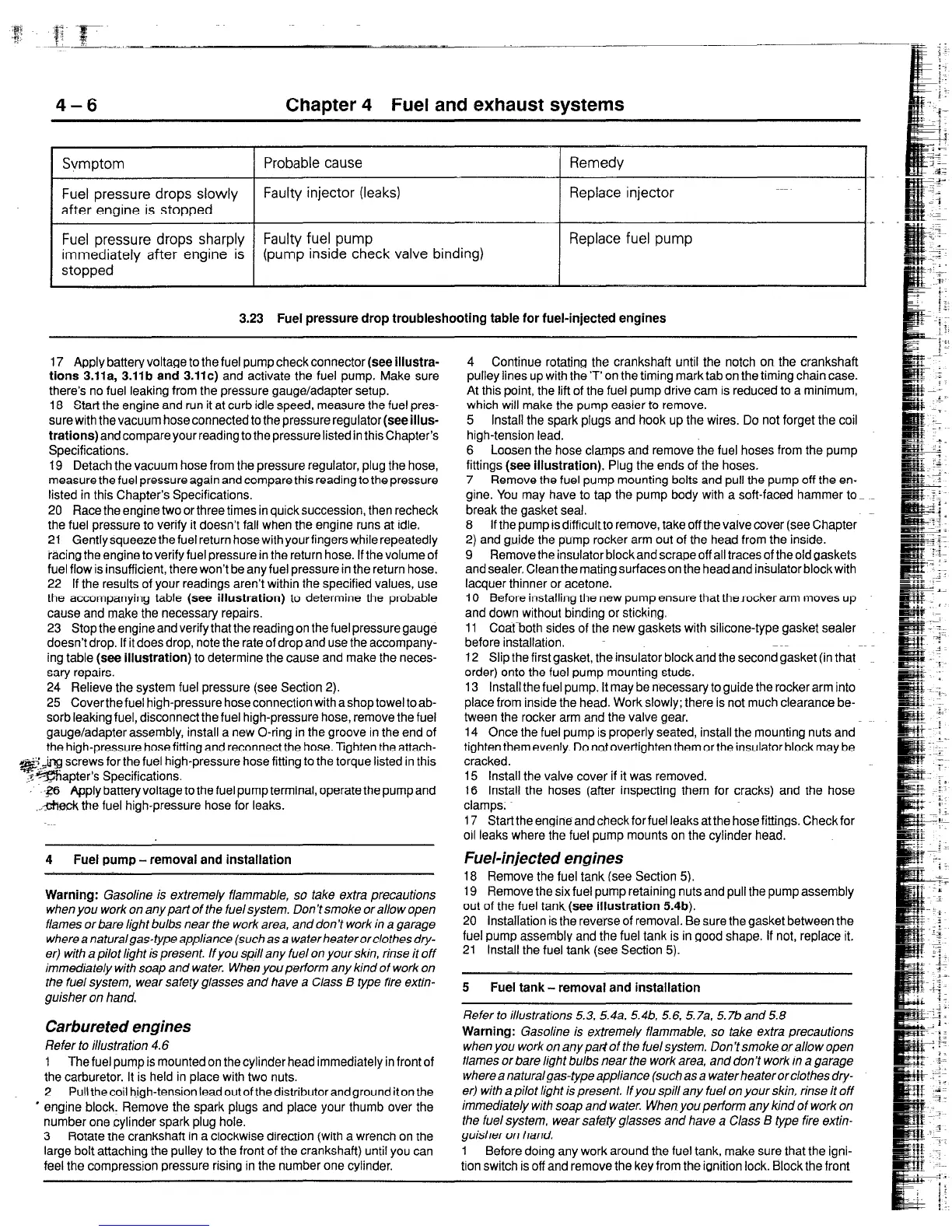

Fuel pressure drops slowly

Faulty injector (leaks) Replace injector

after engine is stopped

Fuel pressure drops sharply Faulty fuel pump

Replace fuel pump

immediately after engine is (pump inside check valve binding)

stopped

3.23 Fuel pressure drop troubleshooting table for fuel-injected engines

17 Apply battery voltage to the fuel pump check connector (see illustra-

tions 3.11a, 3.11b and 3.11~) and activate the fuel pump. Make sure

there’s no fuel leaking from the pressure gauge/adapter setup.

18 Start the engine and run it at curb idle speed, measure the fuel pres-

sure with the vacuum hose connected to the pressure regulator (see illus-

trations) and compare your reading to the pressure listed in this Chapter’s

Specifications.

19 Detach the vacuum hose from the pressure regulator, plug the hose,

measure the fuel pressure again and compare this reading to the pressure

listed in this Chapter’s Specifications.

20 Race the engine two or three times in quick succession, then recheck

the fuel pressure to verify it doesn’t fall when the engine runs at idle.

21 Gentlysqueezethefuelreturn hosewithyourfingerswhilerepeatedly

racing the engine to verify fuel pressure in the return hose. If the volume of

fuel flow is insufficient, there won’t be any fuel pressure in the return hose.

22 If the results of your readings aren’t within the specified values, use

the accompanying table (see illustration) to determine the probable

cause and make the necessary repairs.

23 Stop the engine and verify that the reading on the fuel pressure gauge

doesn’t drop. If it does drop, note the rate of drop and use the accompany-

ing table (see illustration) to determine the cause and make the neces-

sary repairs.

24 Relieve the system fuel pressure (see Section 2).

25 Coverthefuel high-pressure hoseconnection with ashoptowel toab-

sorb leaking fuel, disconnect the fuel high-pressure hose, remove the fuel

gauge/adapter assembly, install a new O-ring in the groove in the end of

the high-pressure hose fitting and reconnect the hose. Tighten the attach-

~@$J?JJ screws for the fuel high-pressure hose fitting to the torque listed in this

,.+$%apter’s Specifications.

-$X5 Apply battery voltage to the fuel pump terminal, operate the pump and

.,.+feck the fuel high-pressure hose for leaks.

4 Fuel pump - removal and installation

Warning: Gasoline is extremely flammable, so take extra precautions

when you work on any part of the fuel system. Don’t smoke or allow open

flames or bare light bulbs near the work area, and don’t work in a garage

wherea naturalgas-typeappliance (suchasa waterheaterorclothesdry-

er) with a pilot light is present. If you spill any fuel on your skin, rinse it off

immediately with soap and water. When youperform any kind of work on

the fuel system, wear safety g/asses and have a Class B type fire extin-

guisher on hand.

Carbureted engines

Refer to illustration 4.6

1 The fuel pump is mounted on the cylinder head immediately in front of

the carburetor. It is held in place with two nuts.

2 Pull the coil high-tension lead out of the distributor and ground iton the

’ engine block. Remove the spark plugs and place your thumb over the

number one cylinder spark plug hole.

3 Rotate the crankshaft in a clockwise direction (with a wrench on the

large bolt attaching the pulley to the front of the crankshaft) until you can

feel the compression pressure rising in the number one cylinder.

4 Continue rotating the crankshaft until the notch on the crankshaft

pulley lines up with the ‘T’on the timing mark tab on the timing chain case.

At this point, the lift of the fuel pump drive cam is reduced to a minimum,

which will make the pump easier to remove.

5 Install the spark plugs and hook up the wires. Do not forget the coil

high-tension lead.

6 Loosen the hose clamps and remove the fuel hoses from the pump

fittings (see illustration). Plug the ends of the hoses.

7 Remove the fuel pump mounting bolts and pull the pump off the en-

gine. You may have to tap the pump body with a soft-faced hammer to

break the gasket seal.

8 If the pump is difficultto remove, take off the valve cover (see Chapter

2) and guide the pump rocker arm out of the head from the inside.

9 Remove the insulator block and scrape off all traces of the old gaskets

and sealer. Clean the mating surfaces on the head and inSulator blockwith

lacquer thinner or acetone.

IO Before installing the new pump ensure that therocker arm moves up

and down without binding or sticking.

11 Coat-both sides of the new gaskets with silicone-type gasket sealer

before installation.

12 Slip the first gasket, the insulator block and the second gasket (in that

order) onto the fuel pump mounting studs.

13 Install the fuel pump. It may be necessary to guide the rocker arm into

place from inside the head. Work slowly; there is not much clearance be-

tween the rocker arm and the valve gear.

14 Once the fuel pump is properly seated, install the mounting nuts and

tighten them evenly. Do notovertighten them or the insulator block may be

cracked.

15 Install the valve cover if it was removed.

16 Install the hoses (after inspecting them for cracks) and the hose

clamps.

17 Start the engine and check for fuel leaks at the hose fittings. Check for

oil leaks where the fuel pump mounts on the cylinder head.

Fuel-injected engines

18 Remove the fuel tank (see Section 5).

19 Remove the six fuel

pump retaining nuts

and pull the pump assembly

out of the fuel tank(see illustration 5.4b).

20 Installation is the reverse of removal. Be sure the gasket between the

fuel pump assembly and the fuel tank is in good shape. If not, replace it.

21 Install the fuel tank (see Section 5).

5 Fuel tank - removal and installation

Refertoillustrations5.3.5.4a.5.4b,5.6. 5.7a. 5.7band5.8

Warning: Gasoline is extremely flammable. so take extra precautions

when you work on any part of the fuel system. Don’t smoke or allow open

flames or bare light bulbs near the work area, and don’t work in a garage

where a naturalgas-type appliance (such as a water heater or clothes dry-

er) with a pilot light is present. If you spill any fuel on your skin, rinse it off

immediately with soap and water. When you perform any kind of work on

the fuel system, wear safzty glasses and have a C/ass B type fire extin-

guisher on hand.

1 Before doing any work around the fuel tank, make sure that the igni-

tion switch is off and remove the key from the ignition lock. Block the front

Loading...

Loading...