ChaWer 4 Fuel and exhaust svstems

Throttle

_ opener

adjusting

screw

SAS-1

SAS-3

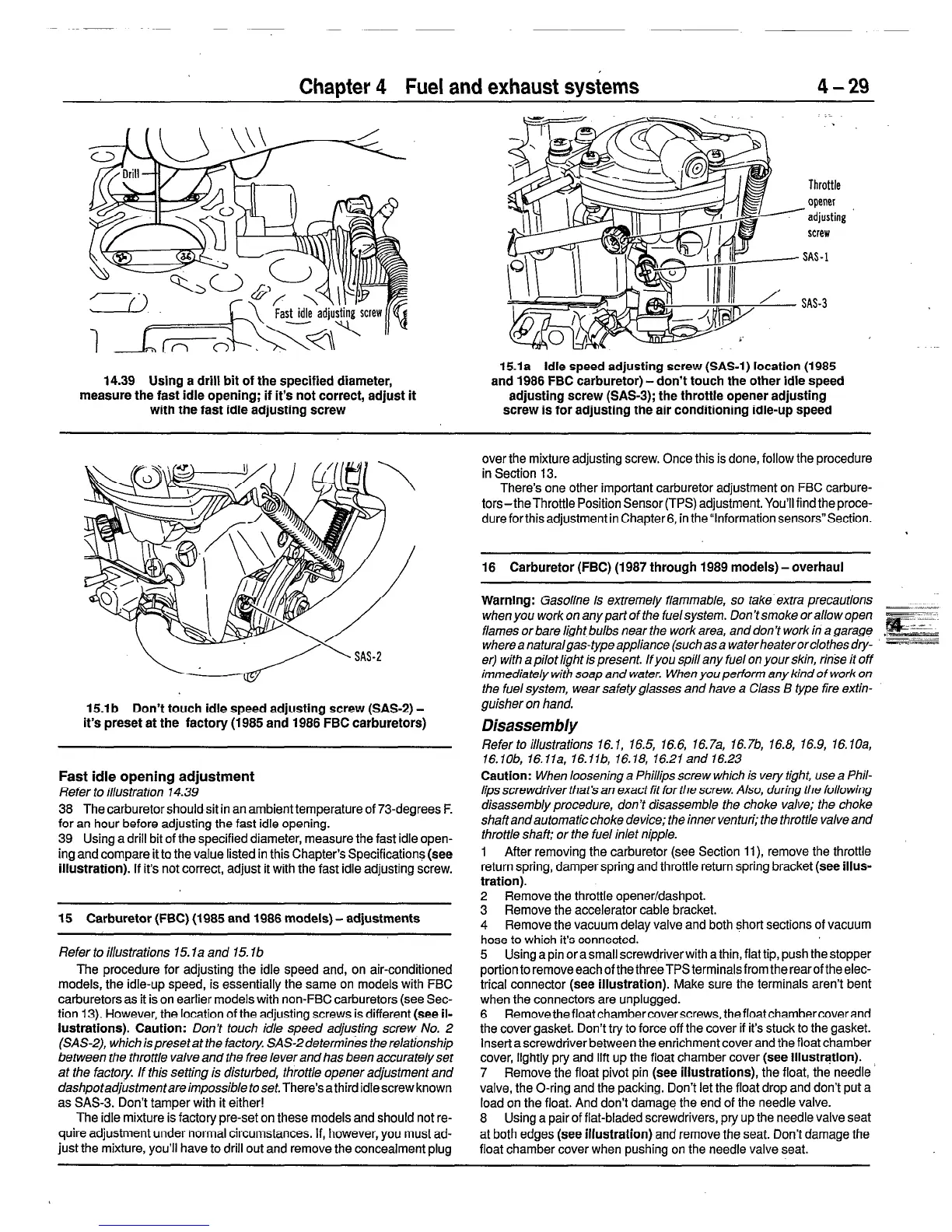

14.39 Using a drill bit of the specified diameter,

measure the fast idle opening; if it’s not correct, adjust it

with the fast idle adjusting screw

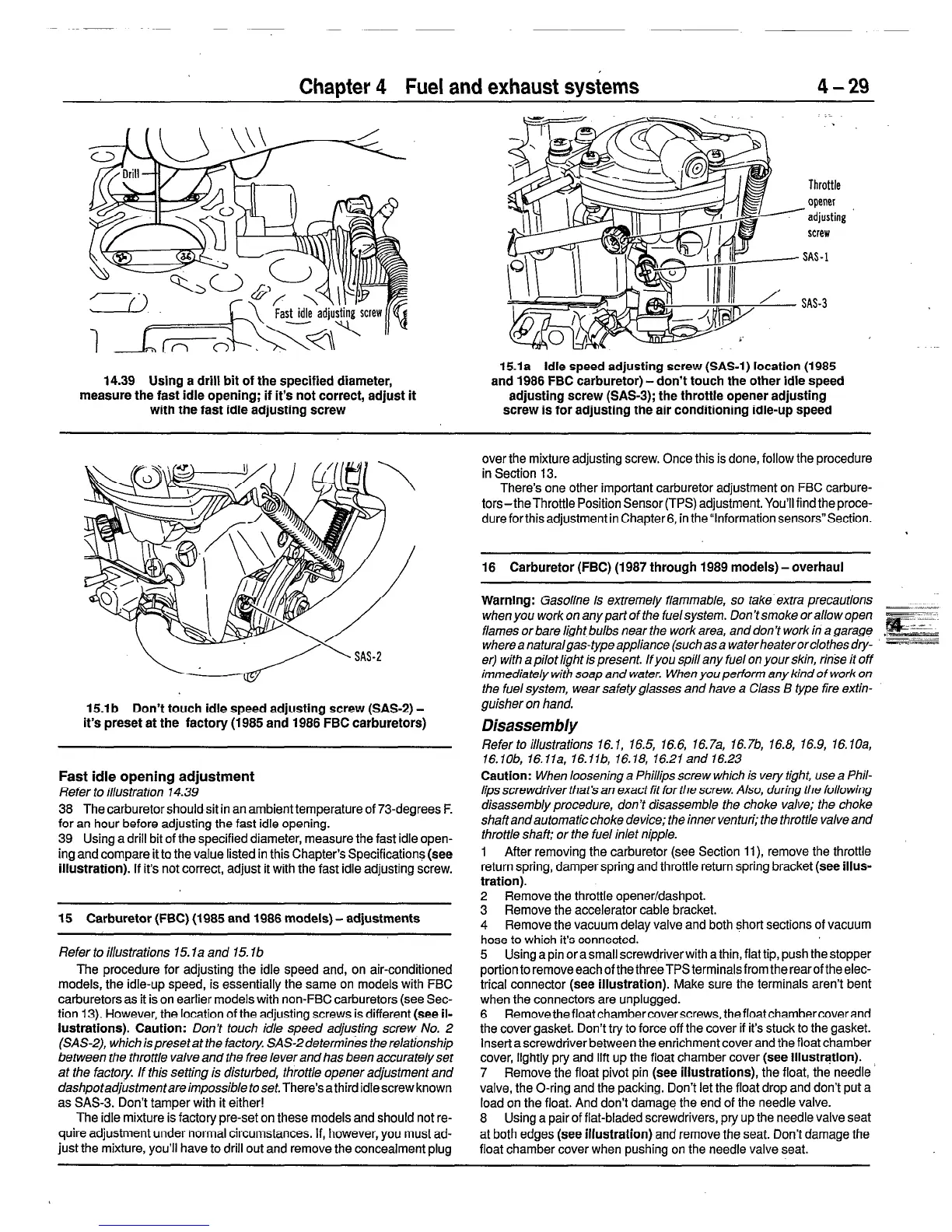

15.la idle speed adjusting screw (SAS-1) location (1985

and 1986 FBC carburetor) - don’t touch the other idle speed

adjusting screw (SAS-3); the throttle opener adjusting

screw is for adjusting the air conditioning idle-up speed

15.lb Don’t touch idle speed adjusting screw (SAS-2) -

it’s preset at the factory (1985 and 1986 FBC carburetors)

Fast idle opening adjustment

Refer to illustration 14.39

38 The carburetor shouldsit in an ambient temperature of 73-degrees F.

for an hour before adjusting the fast idle opening.

39 Using a drill bit of the specified diameter, measure the fast idle open-

ingand compare it to the value listed in this Chapter’s Specification+ (see

illustration). If it’s not correct, adjust it with the fast idle adjusting screw.

15 Carburetor (FBC) (1985 and 1986 models) - adjustments

Refer to illustrations 15. la and 15. lb

The procedure for adjusting the idle speed and, on air-conditioned

models, the idle-up speed, is essentially the same on models with FBC

carburetors as it is on earlier models with non-FBC carburetors (see Sec-

tion 13). However, the location of the adjusting screws is different (see il-

lustrations). Caution:

Don’t touch idle speed adjusting screw No. 2

(SAS-2), which is preset at the factory. SAS-2 determin& the relationship

between the throttle valve and the free lever and has been accurately set

at the factory. If this setting is disturbed, throttle opener adjustment and

dashpotadjustmentareimpossible toset.

There’s athird idle screw known

as SASB. Don’t tamper with it either!

The idle mixture is factory pre-set on these models and should not re-

quire adjustment under normal circumstances. If, however, you must ad-

just the mixture, you’ll have to drill out and remove the concealment plug

over the mixture adjusting screw. Once this is done, follow the procedure

in Section 13.

There’s one other important carburetor adjustment on FBC carbure-

tors - theThrottle Position Sensor (TPS) adjustment. You’ll find the proce-

dure forthis adjustment in Chapter6, in the”lnformation sensors”Section.

16 Carburetor (FBC) (1987 through 1989 models) -overhaul

Warning:

Gasoline is extremely flammable,

so take extra precautions

when you work on any part of the fuel system. Don’t smoke or allow open

flames or bare light bulbs near the work area, and don’t work in a garage

whereanaturalgas-typeappliance (suchasa waterheaterorclothesdty- --==

er) with a pilot light is present. lfyou spill any fuel on your skin, rinse it off

immediately with soap and water. When you perform any kind of work on

the fuel system, wear safety glasses and have a C/ass B type fire extin-

guisher on hand.

Disassembly

Refer to illustrations 16.1, 16.5, 16.6, 16.7a, 16.76, 16.8, 16.9, 16.1Oa,

16.1Ob, 16.11a, 16.11b, 16.18, 16.21and 16.23

Caution:

When loosening a Phillips screw which is very tight, use a Phil-

lips screwdriver that’s an exact fit for the screw. Also, during the following

disassembly procedure, don’t disassemble the choke valve; the choke

shaft and automatic choke device; the inner venturi; the throttle valve and

throttle shaft: or the fuel inlet nipple.

1 After removing the carburetor (see Section ll), remove the throttle

return spring, damper spring and throttle return spring bracket (see illus-

tration).

2 Remove the throttle opener/dashpot.

3 Remove the accelerator cable bracket.

4 Remove the vacuum delay valve and both short sections of vacuum

hose to which it’s connected.

5 Using a pin or a small screwdriver with a thin, fiat tip, push the stopper

portionto removeeachofthethreeTPSterminalsfrom therearoftheelec-

trical connector (see illustration). Make sure the terminals aren’t bent

when the connectors are unplugged.

6 Removethefloatchambercoverscrews,thefloatchambercoverand

the cover gasket. Don’t try to force off the cover if it’s stuck to the gasket.

Insert a screwdriver between the enrichment cover and the float chamber

cover, lightly pry and lift up the float chamber cover (see illusttqtion).

7 Remove the float pivot pin (see illustrations), the float, the needle ’

valve, the O-ring and the packing. Don’t let the float drop and don’t put a

load on the float. And don’t damage the end of the needle valve.

8 Using a pair of flat-bladed screwdrivers, pry up the needle valve seat

at both edges (see illustration) and remove the seat. Don’t damage the

float chamber cover when pushing on the needle valve seat.

Loading...

Loading...