Chapter 1 Tune-up and routine maintenance

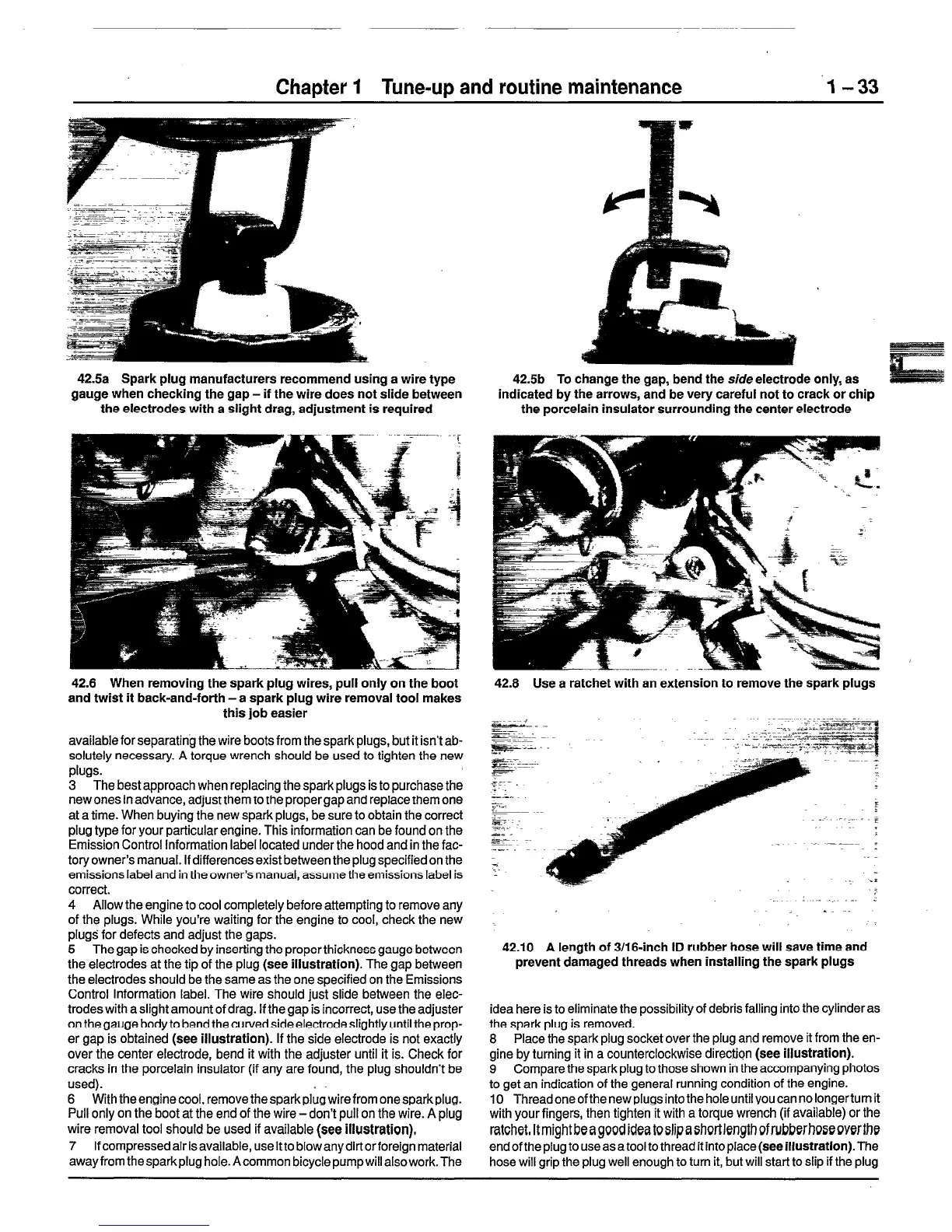

42.5a Spark plug manufacturers recommend using a wire type

gauge when checking the gap - if the wire does not slide between

the electrodes with a slight drag, adjustment is required

42.5b To change the gap, bend the

side

electrode only, as

indicated by the arrows, and be very careful not to crack or chip

the porcelain insulator surrounding the center electrode

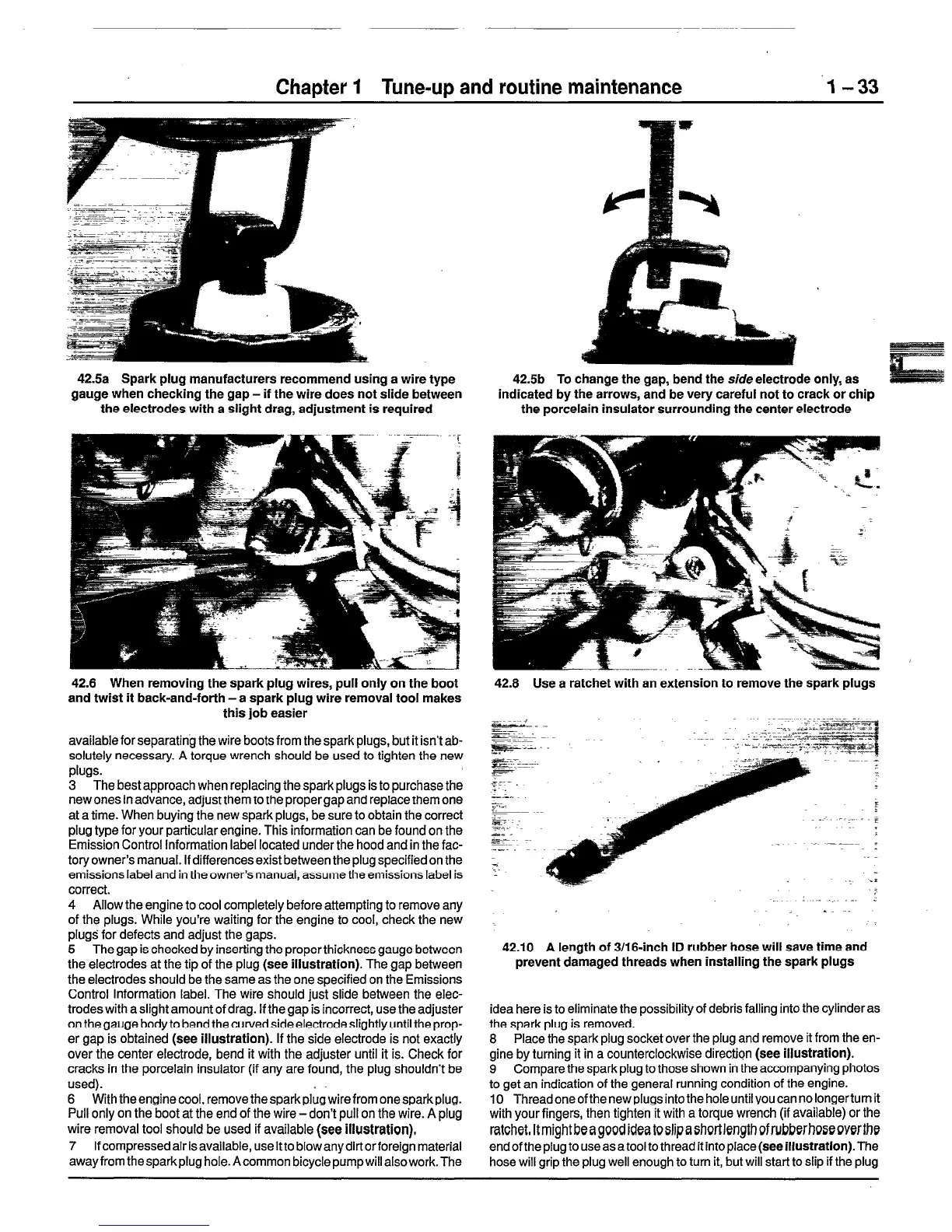

42.6 When removing the spark plug wires, pull only on the boot

and twist it back-and-forth -a spark plug wire removal tool makes

this job easier

available for separating the wire boots from the spark plugs, but it isn’t ab-

solutely necessary. A torque wrench should be used to tighten the new

plugs.

3 The best approach when replacing the sparkplugs is to purchase the

new ones in advance, adjust them to the proper gap and replace them one

at a time. When buying the new spark plugs, be sure to obtain the correct

plug type for your particular engine. This information can be found on the

Emission Control Information label located under the hood and in the fac-

tory owner’s manual. If differences exist between the plug specified on the

emissions label and in the owner’s manual, assume the emissions label is

correct.

4 Allow the engine to cool completely before attempting to remove any

of the plugs. While you’re waiting for the engine to cool, check the new

plugs: for defects and adjust the gaps.

5 The gap is checked by inserting the proper thickness gauge between

the electrodes at the tip of the plug

(see illustration).

The gap between

the electrodes should be the same as the one specified on the Emissions

Control Information label. The wire should just slide between the elec-

trodes with a slight amount of drag. If the gap is incorrect, use the adjuster

on the gauge body to bend the curved side electrode slightly until the prop-

er gap is obtained

(see illustration).

If the side electrode is not exactly

over the center electrode, bend it with the adjuster until it is. Check for

cracks in the porcelain insulator (if any are found, the plug shouldn’t be

used). .

6 With theenginecool, removethesparkplugwirefromonesparkplug.

Pull only on the boot at the end of the wire-don’t pull on the wire. A plug

wire removal tool should be used if available

(see illustration),

7 If compressed air is available, use it to blow any dirt or foreign material

awayfrom thesparkplug hole.Acommon bicyclepumpwillalsowork.The

42.8 Use a ratchet with an extension to remove the spark plugs

: _. _

42.10 A length of 3/16-inch ID rubber hose will save time and

prevent damaged threads when installing the spark plugs

idea here is to eliminate the possibility of debris falling into the cylinder as

the spark plug is removed.

8 Place the spark plug socket over the plug and remove it from the en-

gine by turning it in a counterclockwise directiQn

(see illustration).

9 Compare the spark plug to those shown in the accompanying photos

to get an indication of the general running condition of the engine.

10 Threadoneofthenewplugsintotheholeuntilyoucannolongertumit

with your fingers, then tighten it with a torque wrench (if available) or the

ratchet, ItmightbeagoQdideatoslipashQrtlengthQfrubberhoseQYerthe

endoftheplugto useasatool tothreadit

intoplace(seeillustration).The

hose will grip the plug well enough to turn it, but will start to slip if the plug

Loading...

Loading...