Chapter 2 Part C 3.OL V6 engine 2C-13

TIMING

BELT

END

CYLINDiR HEAD

BOLT $ND WASHER

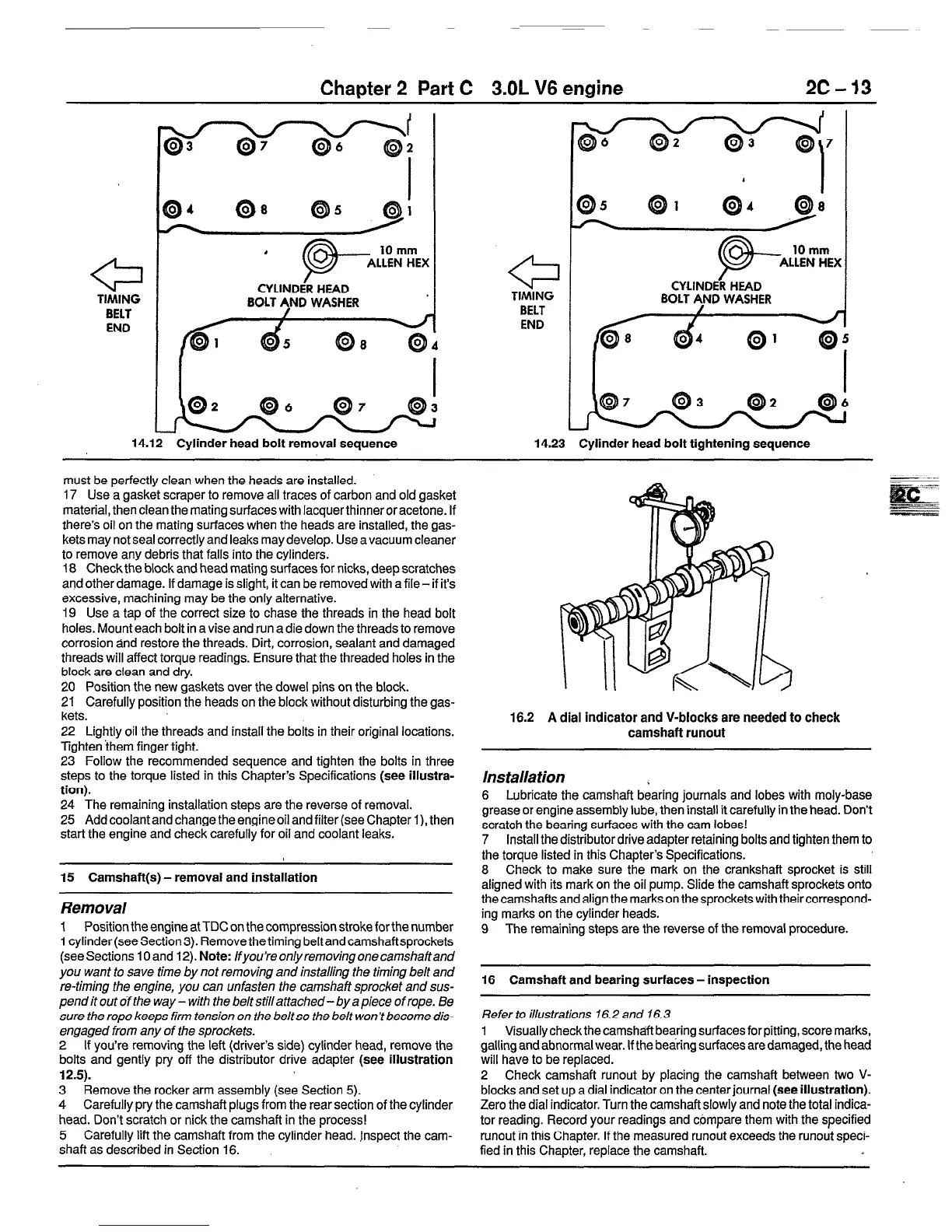

14.12 Cylinder head bolt removal sequence

TIMING

BELT

END

14.23

Cylinder head bolt tightening sequence

P-

10 mm

ALLEN HEX

CYLINDER HEAD

BOLT A,ND WASHER

must be perfectly clean when the heads are installed.

17 Use a gasket scraper to remove all traces of carbon and old gasket

material, then clean the mating surfaces with lacquerthinner or acetone. If

there’s oil on the mating surfaces when the heads are installed, the gas-

kets may not seal correctly and leaks may develop. Use a vacuum cleaner

to remove any debris that falls into the cylinders.

18 Check the block and head mating surfaces for nicks, deep scratches

and other damage. If damage is slight, it can be removed with a file- if it’s

excessive, machining may be the only alternative.

19 Use a tap of the correct size to chase the threads in the head bolt

holes. Mount each bolt in a vise and run a die down the threads to remove

corrosion and restore the threads. Dirt, corrosion, sealant and damaged

threads will affect torque readings. Ensure that the threaded holes in the

block are clean and dry.

20 Position the new gaskets over the dowel pins on the block.

21 Carefully position the heads on the block without disturbing the gas-

kets.

22 Lightly oil the threads and install the bolts in their original locations.

Tighten them finger tight.

23 Follow the recommended sequence and tighten the bolts in three

steps to the torque listed in this Chapter’s Specifications (see illustra-

tion).

24 The remaining installation steps are the reverse of removal.

25 Add coolant and change the engine oil and filter (see Chapter I), then

start the engine and check carefully for oil and coolant leaks.

15 Camshaft(s) - removal and installation

Removal

1 Position the engine at TDC on the compression stroke for the number

1 cylinder (see Section 3). Remove the timing belt and camshaft sprockets

(seesections 10 and 12). Note:

Ifyou’reonlyremovingonecamshaftand

you want to save time by not removing and installing the timing belt and

re-timing the engine, you can unfasten the camshaft sprocket and sus-

pend it out of the way - with the belt still attached - by a piece of rope. Be

sure the rope keeps firm tension on the be/t so the be/t won’t become dis-

engaged from any of the sprockets.

2 If you’re removing the left (driver’s side) cylinder head, remove the

bolts and gently pry off the distributor drive adapter (see illustration

12.5).

3 Remove the rocker arm assembly (see Section 5).

4 Carefully pry the camshaft plugs from the rear section of the cylinder

head. Don’t scratch or nick the camshaft in the process!

5 Carefully lift the camshaft from the cylinder head. Jnspect the cam-

shaft as described in Section 16.

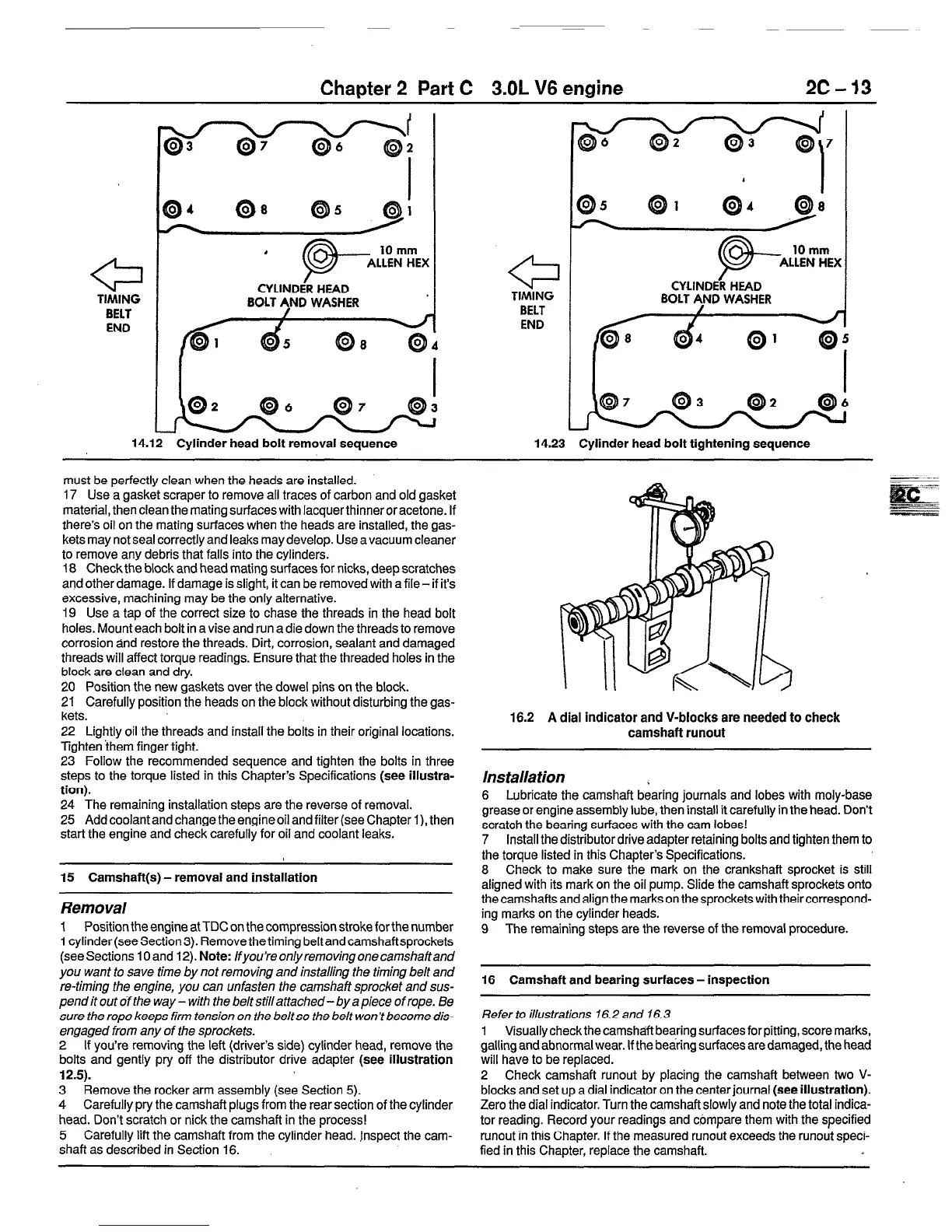

16.2 A dial indicator and V-blocks are needed to check

camshaft runout

Ins talla tion

6 Lubricate the camshaft bearing journals and lobes with moly-base

grease or engine assembly lube, then install it carefully in the head. Don’t

scratch the bearing surfaces with the cam lobes!

7 Install the distributor drive adapter retaining bolts and tighten them to

the torque listed in this Chapter’s Specifications.

8 Check to make sure the mark on the crankshaft sprocket is still

aligned with its mark on the oil pump. Slide the camshaft sprockets onto

the camshafts and align the marks on the sprockets with theircorrespond-

ing marks on the cylinder heads.

9 The remaining steps are the reverse of the removal procedure.

16 Camshaft and bearing surfaces - inspection

Refer to illustrations 16.2 and 16.3

1 Visuallycheckthecamsha’ftbearingsurfacesforpitting,scoremarks,

galling and abnormal wear. If the bearing surfacesaredamaged, the head

will have to be replaced.

2 Check camshaft runout by placing the camshaft between two V-

blocks and set up a dial indicator on the center journal (see illustration).

Zero the dial indicator. Turn the camshaft slowly and note the total indica-

tor reading. Record your readings and compare them with the specified

runout in this Chapter. If the measured runout exceeds the runout speci-

fied in this Chapter, replace the camshaft.

Loading...

Loading...