70 / 195

Service Manual Mitsubishi SL-Series diesel engines

Version 08/2004

ENGLISH

TIMING GEARS AND FLYWHEEL INSPECTION

70 / 195

2. Idler shaft replacement

Install a new idler shaft to the cylinder block so that

its dimension from the face of the block is 26.5±0.5

mm (1.043±0.020 in.).

18.5 Flywheel and ring gear

1. Flatness (difference between lower and higher

measurements) of flywheel

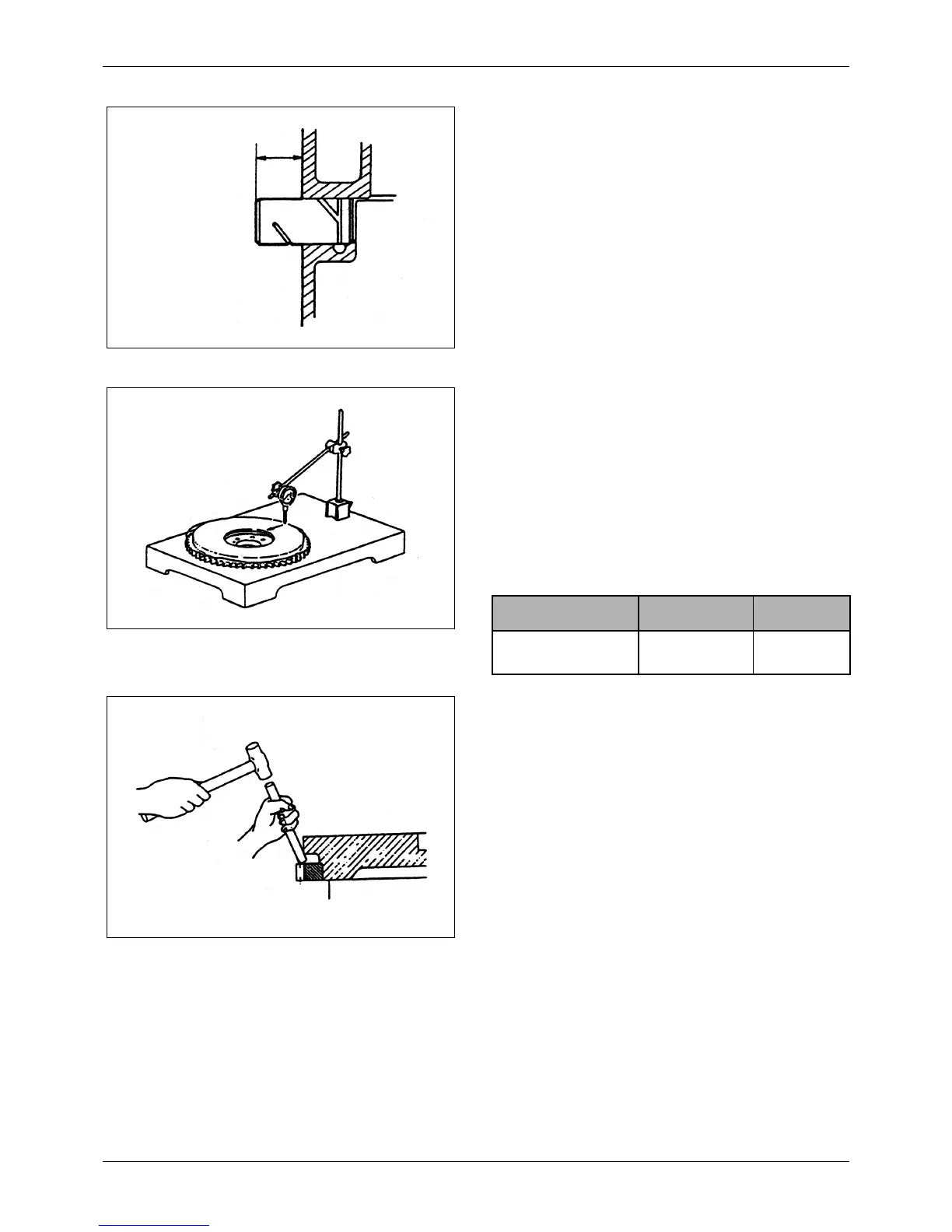

Put the flywheel on the surface plate. Set a dial

indicator at one side of the friction (clutch contact)

face and move it over to the opposite side of the

face as shown in the illustration to find the flatness.

If the flatness exceeds the limit, grind the face.

Unit: mm (in.)

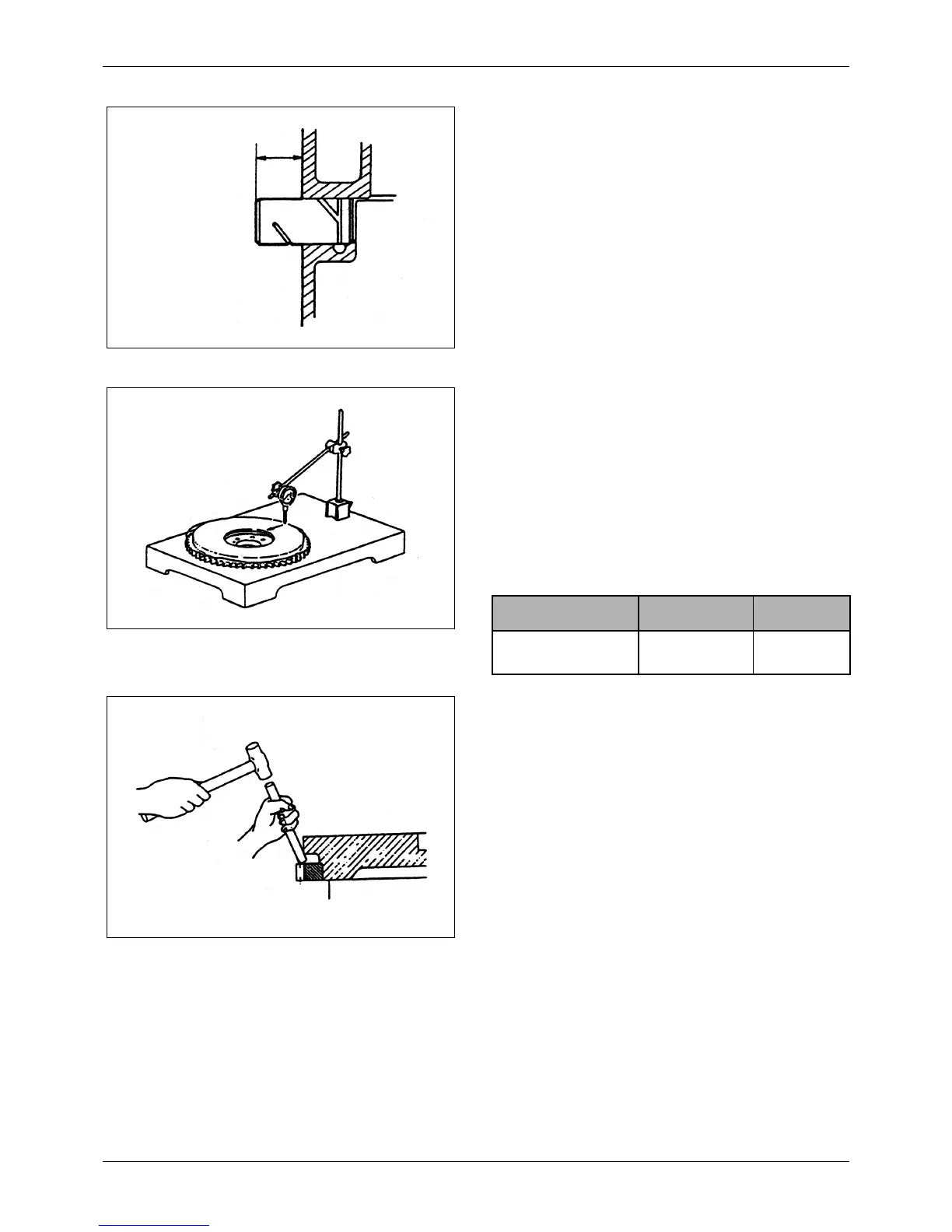

2. Ring gear replacement

Check the ring gear and replace it if its teeth are

abnormally worn or chipped.

1) Removal

Heat the ring gear evenly with an acetylene

torch. Tap the ring gear all the way around

with a bar and a hammer as shown in the

illustration to remove it from the flywheel.

2) Installation

Heat a new ring gear up to a temperature of

150°C (302°F) with a piston heater and install

it to the flywheel with its unchamfered side

foremost.

Figure 90 Idler shaft dimension

26,5 ± 0.5 mm

(1.043 ± 0.020 in.)

Figure 91 Measering flywheel flatness

Item Standard Limit

Flatness of

flywheel

0.15 (0.005 9)

maximum

0.50

(0.019 7)

Figure 92 Removing ring gear

Loading...

Loading...