Chapter Two: Installation Interface Cables

15

Special Consideration for the Ground Connection

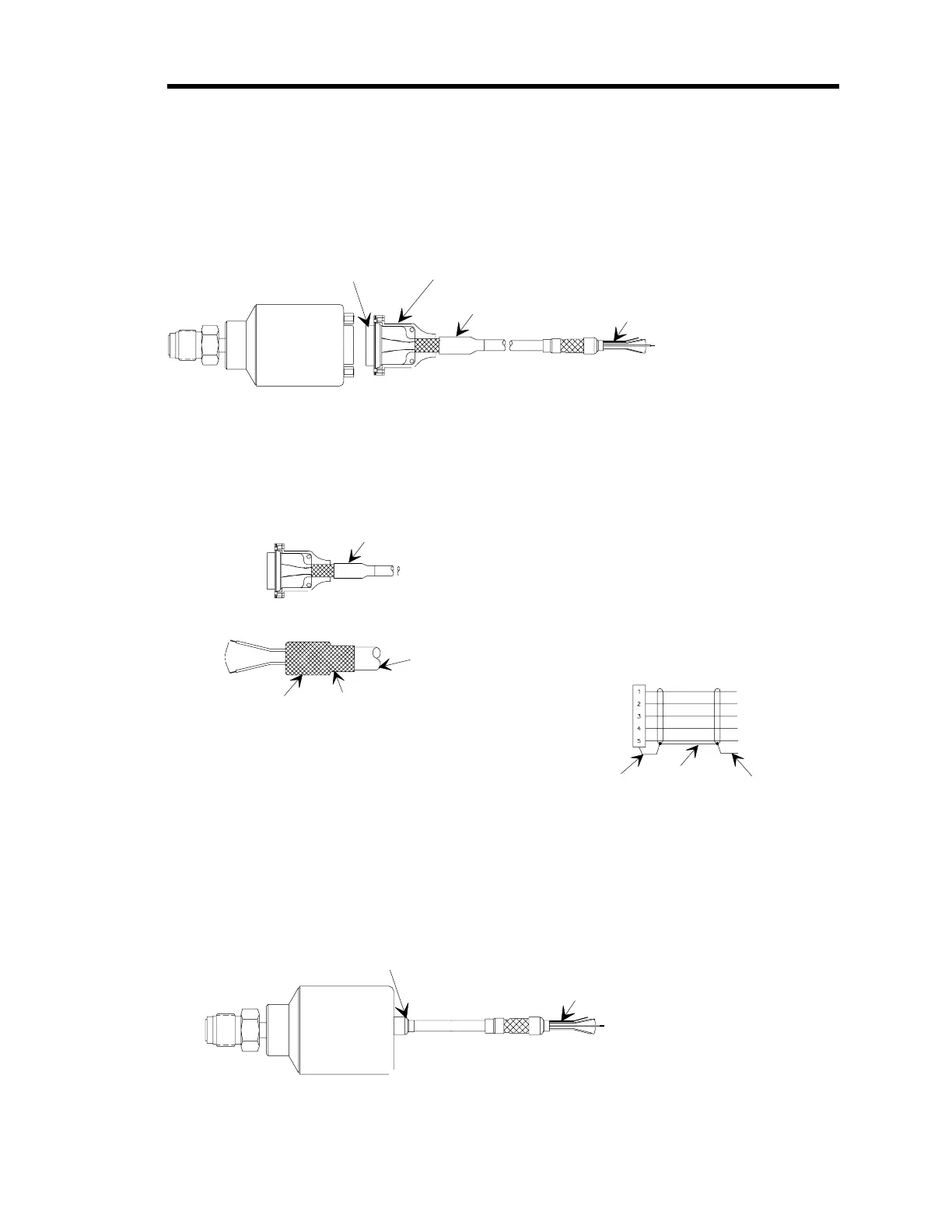

If you choose to make your own cable you must properly ground the cable on both ends to ensure

electromagnetic integrity and compliance with CE regulations. Figure 4 identifies the

components of a cable designed to connect to a Type “D” connector on the pressure switch.

Metal Shell

Type "D" Connector

Heat Shrink Tubing

Bare Metal Shield (Drain) Lead (1)

}

Signal Leads (5)

Figure 4: Components of a Cable to Connect to a Type “D” Connector

On the connector end of the cable, Figure 5 shows how the metal braided shield is folded back

over itself to expose the wires. Then the metal shell of the connector is clamped over the metal

braided shield to form a good contact point.

Type "D"

Connector

Wiring Diagram

Power Return

Power Input

Relay N/O

Relay Common

Relay N/C

Braided

Shield

Cable Outer Jacket

Metal Braided Shield

Notes

1. Build up with heat shrink tubing over outer jacket.

2. Pull metal braided shield over outer jacket.

Refer to Note 1

To User

Connections

}

Bare Metal Shield

(Drain) Lead

Connection made with

the metal shell clamped

over the metal braided shield.

Figure 5: Expanded View of the Cable

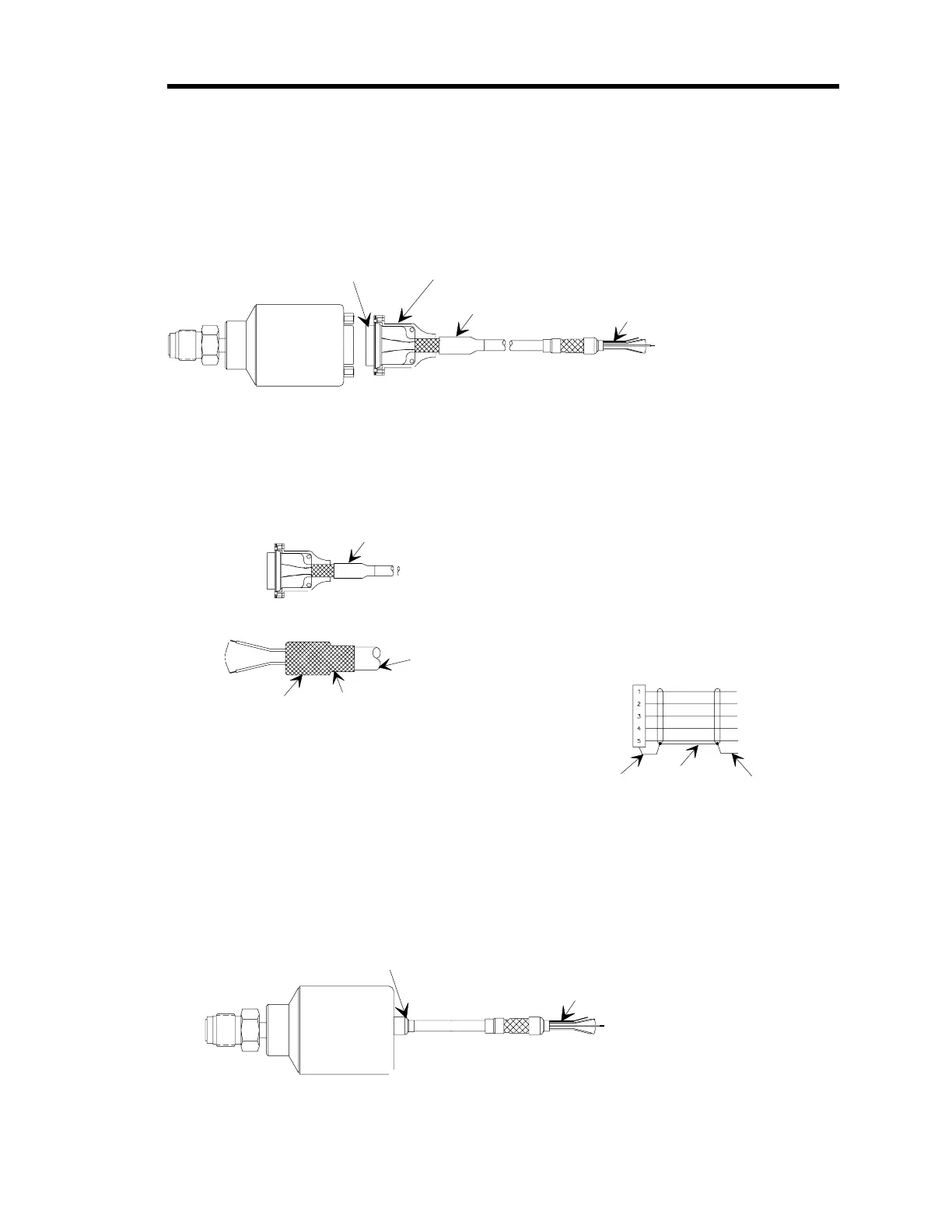

At the flying leads end of the cable, connect the shield (drain) lead to the main ground of your

system using the shortest length of shield (drain) lead possible.

Flying Leads Connector

Bare Metal Shield (Drain) Lead (1)

}

Signal Leads (5)

Figure 6: Flying Leads Connector

Loading...

Loading...