PART 5: BOILER PIPING (CONTINUED)

I. FILL AND PURGE HEATING SYSTEM

• Attach the hose to balance and purge hose

connector or drain valve and run hose to

nearest drain

• Close the other side of the balance and purge

valve or the shut off valve after the drain.

• Open first zone balance and purge or drain

valve to let water flow out the hose. If zone

valves are used, open the valves one at a

time manually. (Note: You should check valve

manufacturer’s instruction prior to opening

valves manually, so as not to damage the

valve.)

• Manually operate fill valve regulator. When

water runs out of the hose, while it’s

connected to the balance and purge valve or

drain you will see a steady stream of water

(without bubbles). Close balance and purge

valve or drain to stop the water from flowing.

Disconnect the hose and connect it to next

zone to be purged.

• Repeat this procedure for additional zones

(one at time).

Figure 5-2

GAS-FIRED BOILER

Boiler Manual

22

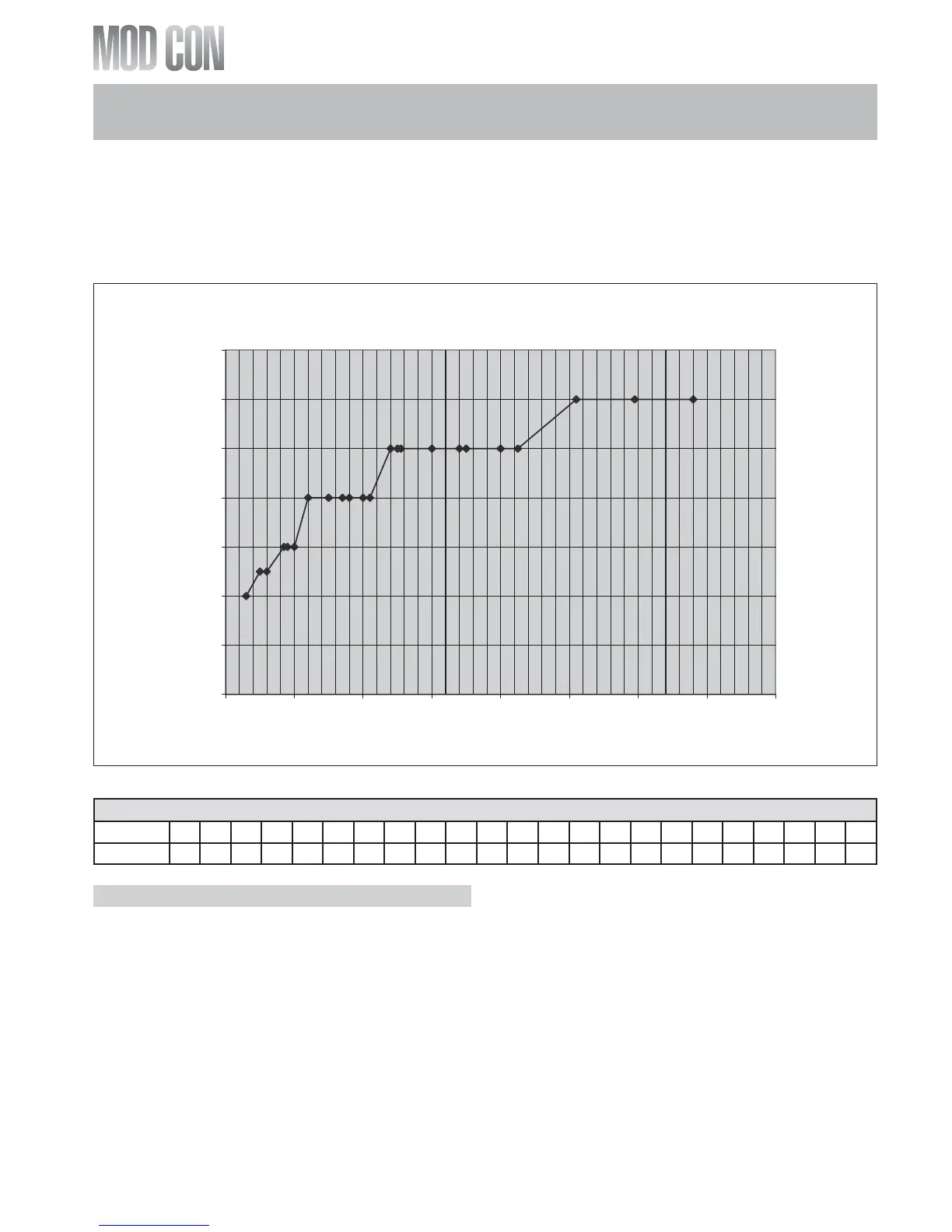

Combined Boiler Pipe Sizing

0

1

2

3

4

5

6

7

0 100 200 300 400 500 600 700 800

Combined Boiler Water Flow (GPM)

Pipe Diameter Size (Inches)

Multiple Boiler Manifold Piping

The chart below represents the combined flow

rates and pipe sizes when using multiple boilers

to design the manifold system for the primary

circuit. To size, simply add up the number of

boilers and the required flow rates for the sys-

tem design temperature.

Example (5) Mod Con 300 Boilers with a design

of 30 degree temperature rise with each boiler

having an individual flow rate of 20 GPM. To cor-

rectly size the manifold feeding these (5) Mod

Con 300 Boilers you would need a pipe size of

3”.

MULTIPLE BOILER MANIFOLD PIPING

Flow rate 30 50 60 85 90 100 120 150 170 180 200 210 240 250 255 300 340 350 400 425 510 595 680

Pipe Dia. 2” 2½” 2½” 3” 3” 3” 4” 4” 4” 4” 4” 4” 5” 5” 5” 5” 5” 5” 5” 5” 6” 6” 6”

Loading...

Loading...