Page 24

INSTALLATION REQUIREMENTS

INSTALLER MUST CHECK THE FOLLOWING LIST WHEN INSTALLING

A MOLNAR FOUR-POST HOIST

1. Asuitable floor where the hoist is to be bolted down must have a level surface. When the hoist

is bolted down check all nuts and bolts to ensure they are correctly tightened.

2. Check wire ropes and sheaves for possible transport damage or dislocation.

3. When power is connected to the hoist the motor must rotate clockwise. If hoist will not lift

exchange wires on two phases (by an Electrician).

4. Check hoist for loose nuts or bolts.

5. Check operation of safety mechanism on all posts, then test hoist with load.

6. Recheck hoist operation. Demonstrate the hoist to the operator.

7. Very important

7.1 Instruct operator how to use the hoist.

7.2 Point out maintenance requirements on wire ropes and that they should be checked monthly.

7.3 Point out that by law, the operator and/or owner are responsible for the maintenance and safe

operation of the hoist.

8. When all the above points are checked the certificate must be signed by the installer.

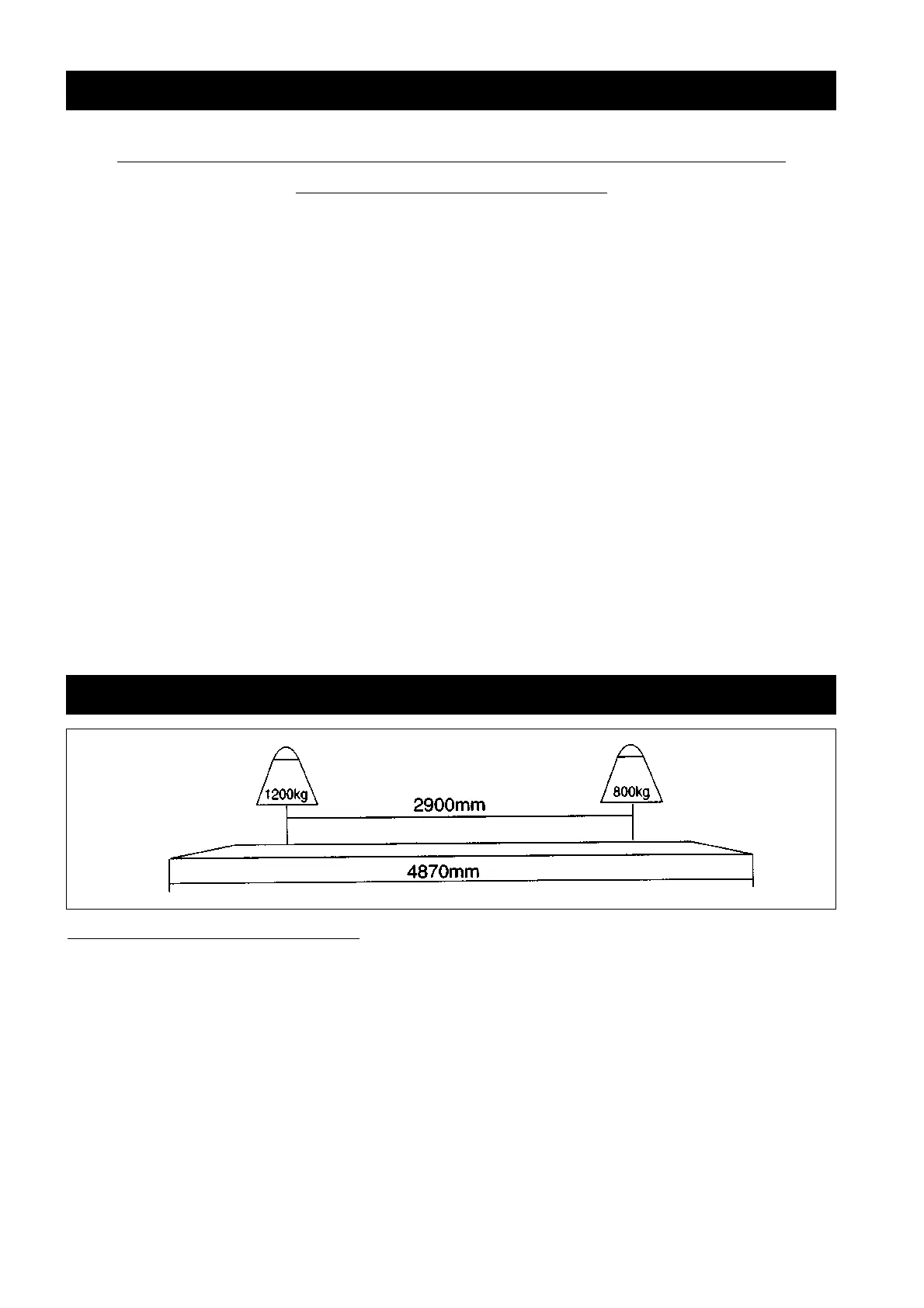

PROCEDURE FOR LOADING RAILS

Each rail has a maximum load of 2000kg, with a 60/40 distribution at a minimum

span between the loading points of 2900mm.

Example 1. Car mass = 4000kg

Mass per rail = 2000kg

Distribution 60/40 = 1200/800kg

Min span = 2900mm

Example 2. Car mass = 2600kg

Mass per rail = 1300kg

Distribution 60/40 = 780/520kg

Min span = 300mm

NOTE: Lifting the car at the centre of the rails is not advisable (for stability reasons).

WHEELS - FREE RAILS

Loading...

Loading...