*REFER TO CHECK SHEET FIRST

1/99

SAFETY MAINTENANCE

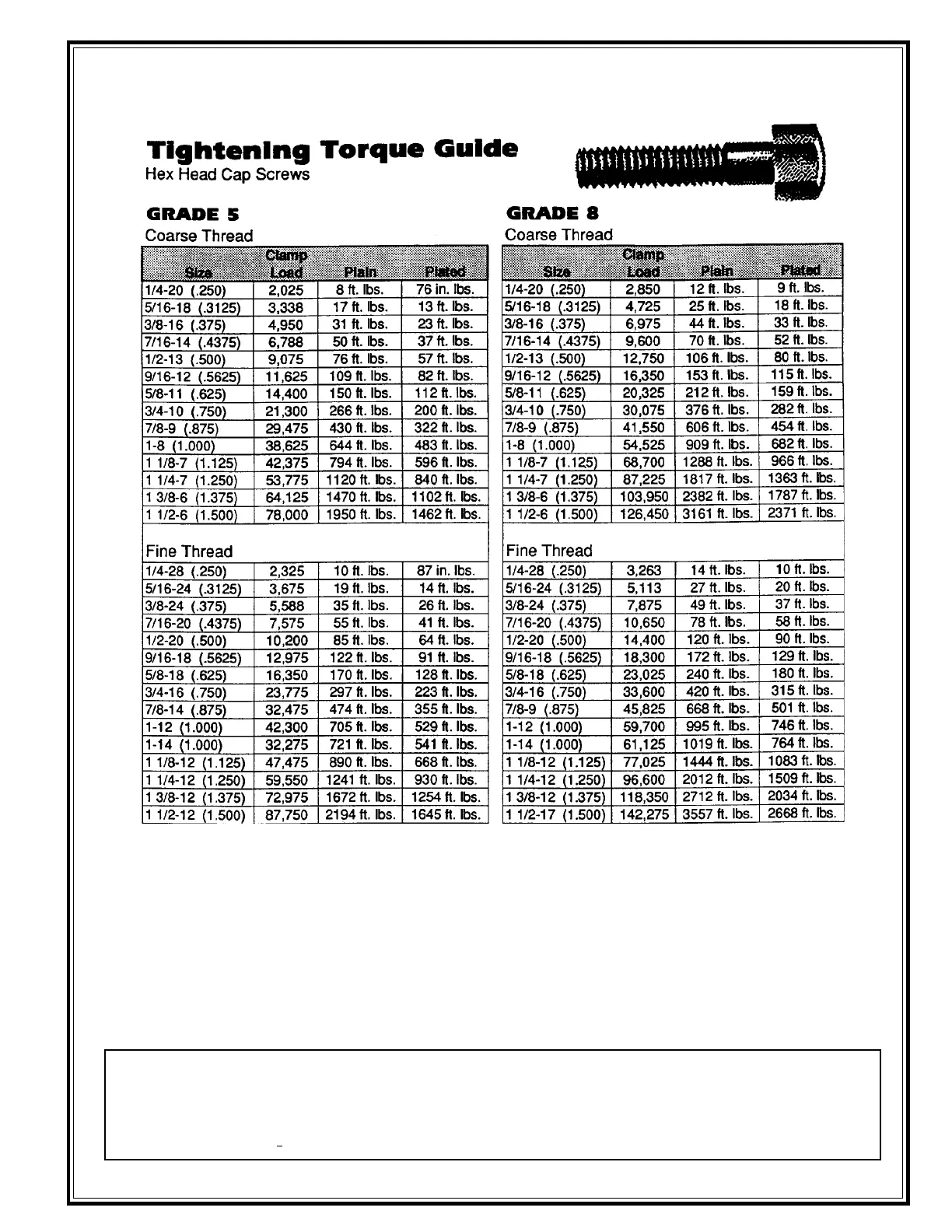

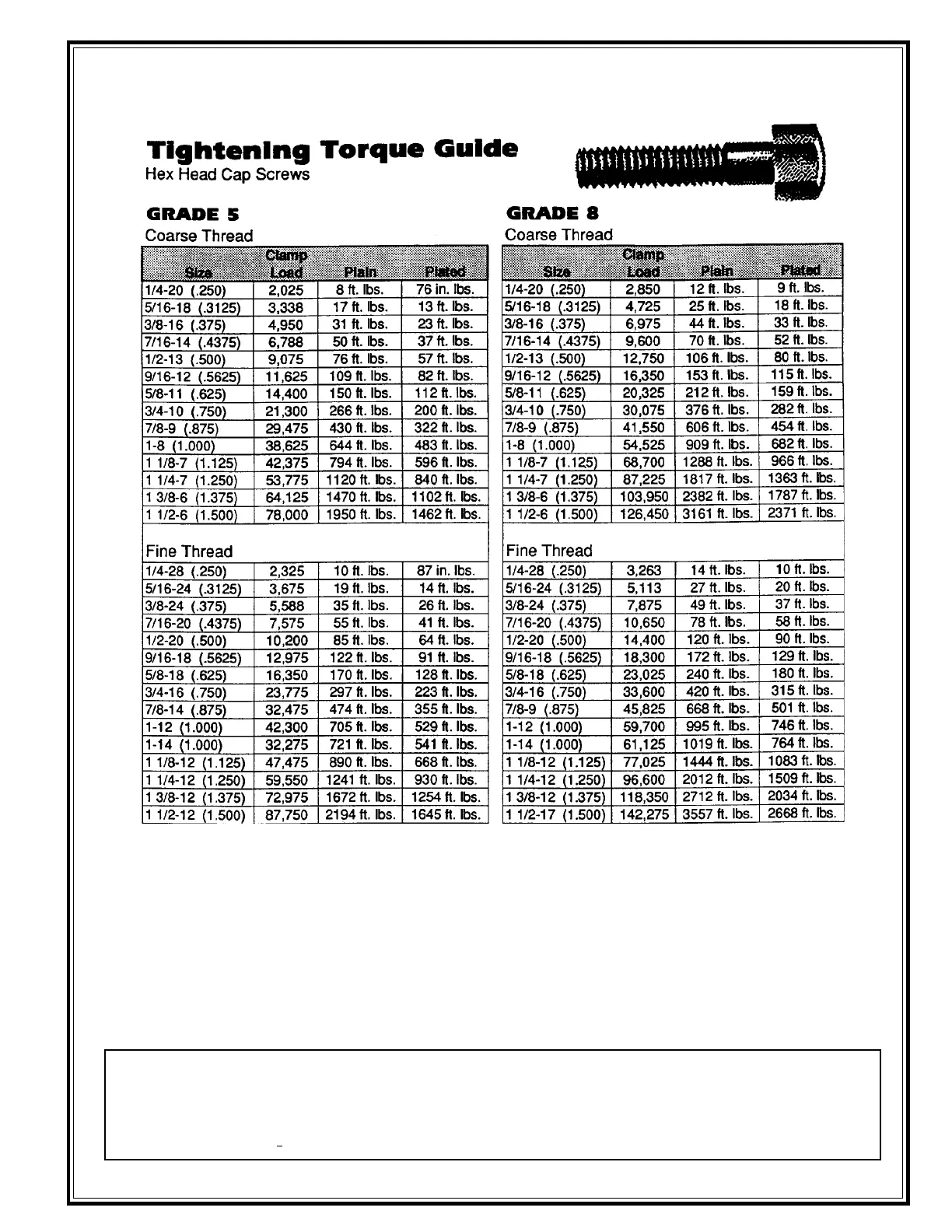

**Based on IFI 5th Edition Technical Data N-12/N-16, using Equation (1) and a torque coefficient, K=0.20 for nonplated steel fasteners and K=0.15 for plated fasteners.

These Figures represent an estimate of torque (torque being the measurement of friction, not tension) required to induce given preload (clampload) in a bolt for noncritical applications

only. For critical or special applications where greater control is desired this should be experimentally determined. This applies to washer faced or double chamfered hex nuts (or bolts,

if bolt is torqued) having a width across flats of approximately 1.5 times the nominal diameter and having threads free of interference.

Because of the many interrelated variables that directly or indirectly affect friction, such as surface texture, type of coating or finish, lubrication, speed of tightening , human error, etc.,

it is possible to experience as much as

+25% deviation in preload (clampload) with the use of a torque wrench.

NOTES:

1. Always use the torque values above when specific torque values are not available.

2. Do not use above values in place of those specified in other sections of this manual; special attention should be observed when using SAE

Grade 6, 7 and 8 capscrews.

3. The above is based on use of clean, dry threads.

4. Reduce torque by 10% when engine oil is used as a lubricant.

5. Reduce torque by 20% if new plated capscrews are used.

6. Capscrews threaded into aluminum may require reductions in torque of 30% or more of Grade 5 capscrews torque and must attain two

capscrew diameters of thread engagement.

Caution: If replacement capscrews are of a higher grade than originally supplied, adhere to torque specifications for that placement.

22

Loading...

Loading...