Page 4 of 24 FLOMAX 8 BZ AL (en)

STORAGE PRECAUTIONS

Do not store filled with fluid at or below freezing temp of

process uid.

INSTALLATION

INSTALLATION FOR FLOMAX SELF PRIMING PUMPS

:

For optimum performance, place pump as close to liquid

source as possible to reduce suction lift to a minimum. For

best results, pump should be installed not more than 15 feet

above the liquid supply. Set the unit on solid footing and as

nearly level as possible.

Pipe or hose of the same size as anges provided should be

used. Reinforced rubber suction hose is recommended be-

cause it provides greater flexibility and prevents collapsing

due to vacuum in the suction line when pump is in operation.

Suction line should be as short as possible and have as few el-

bows or bends as possible to keep friction loss at a minimum.

Use pipe dope on all connections and make certain that all

ttings are tight, particularly on the suction line where an air

leak can prevent priming or reduce pump capacity.

A good suction strainer should be used. Suction strainers are

available from your MP Distributor. Refer to the accessory

section of the GENERAL PUMP PRICE LIST for the correct part

number

INSTALLATION FOR FLOMAX PUMPAKS:

Be sure that the pump housing is filled with liquid before

starting the pump. THE MECHANICAL SEAL IN THE PUMP

MUST NOT BE OPERATED DRY.

Pipe or hose of the same size (or larger) as inlet and outlet

openings should be used on the installation. When using

pipe, avoid sharp bends and use long radius elbows wherev-

er possible. This will keep friction loss at a minimum and al-

low the pump to operate more eectively. Use pipe dope on

all connections and be sure all ttings are airtight, especially

on the suction side of the pump. An air leak on the suction

side of the pump will prevent proper operation. A section of

non-collapsible hose between piping and pump may be used

as a vibration dampener.

BEARING INSTALLATION (PEDESTAL MODELS):

Check the shaft to insure that it rotates freely. Shafts should

be aligned in accordance with the instructions of the cou-

pling manufacturer. Final alignment must be performed after

the pump has been completely installed and the pump and

driver are at operating temperature. Proper shaft alignment is

the responsibility of the installer.

Piping should include shuto valves on both the discharge

and suction to isolate the pump for maintenance. Provisions

for suction and discharge pressure gages are recommended

for trouble shooting. The suction line should be as short as

possible, at least as large as the pump suction connection,

include as few ttings as possible and those should be long

radius to keep friction losses at a minimum.

Both suction and discharge piping should be supported in-

dependently of the pump. Never use excessive force to move

the pipe into place. This may impose a strain that will result

in misalignment between the pump and driver or otherwise

adversely aect the operation of the pump. After connecting

pipe to the pump rotate the shaft several times to check for

rubbing or binding.

NSTALLATION FOR FLOMAX SELF PRIMING PUMPS

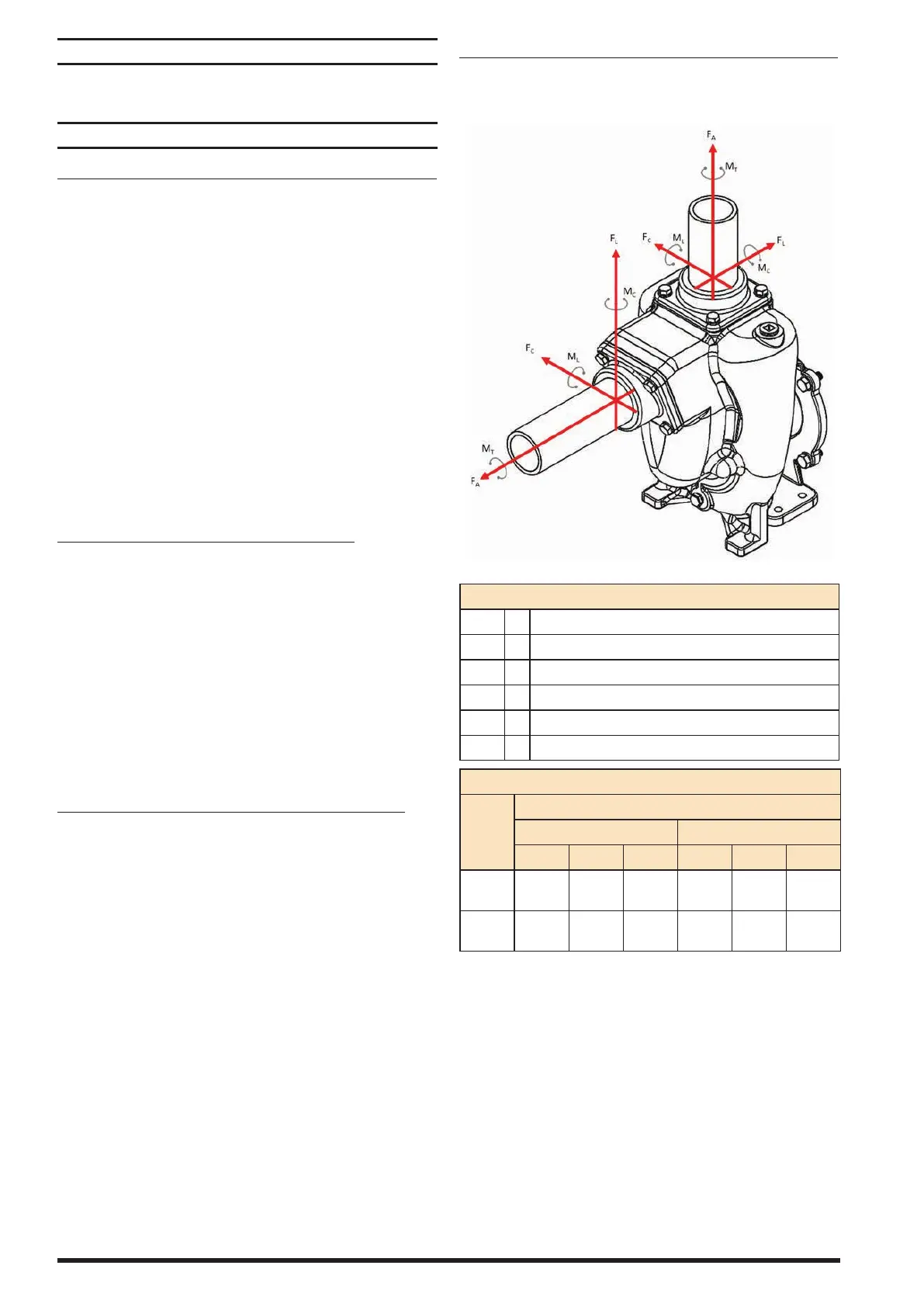

The permitted forces and moments on pump inlet

and outlet.

LEGENDS

F

L

- Longitudinal shear force

F

C

- Circumferential shear force

F

A

- Axial tension or compression force

M

L

- Longitudinal bending force

M

C

- Circumferential bending force

M

T

- Torsional moment

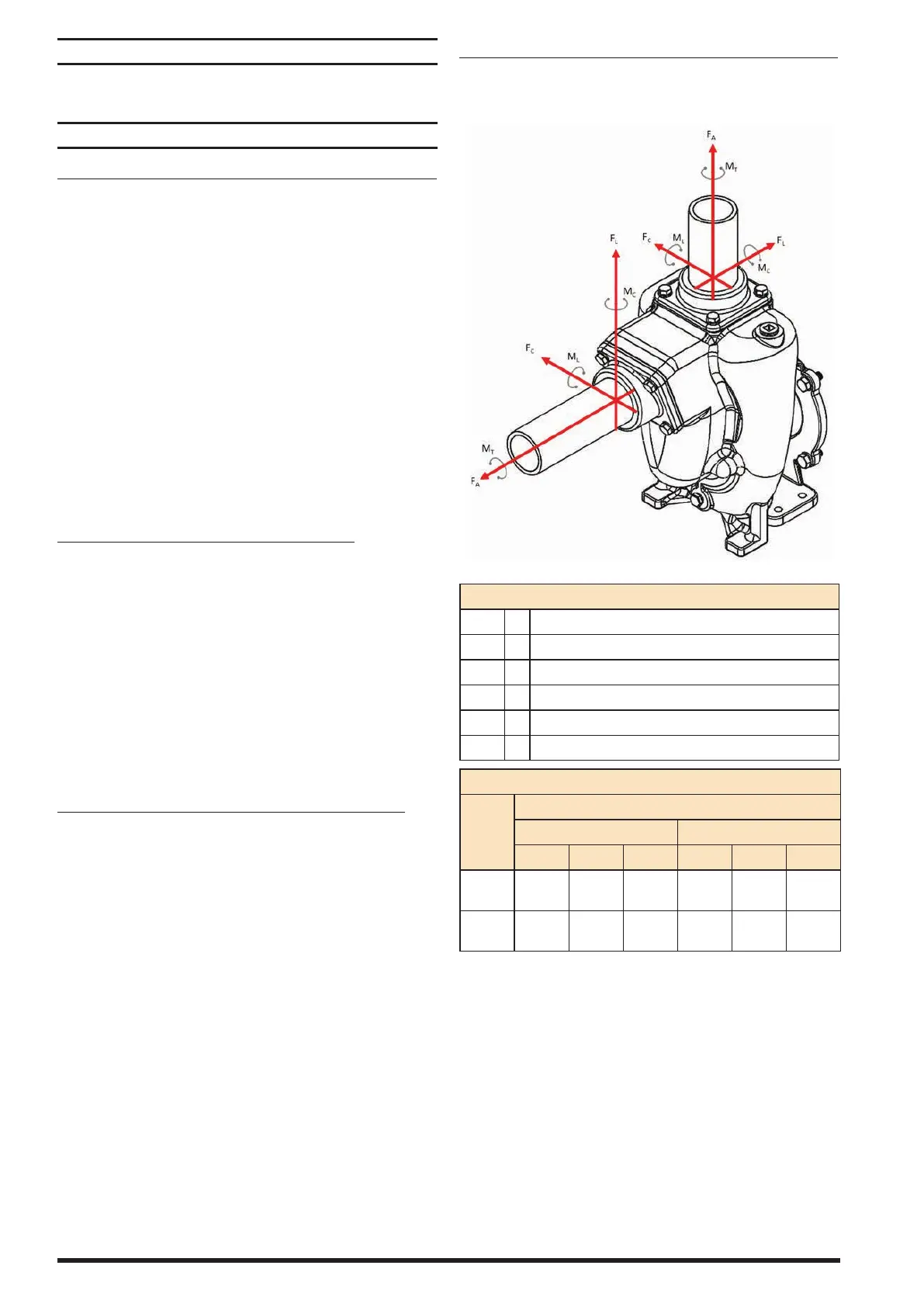

ALLOWABLE NOZZLE LOADS

Nozzle

Size

(in)

Small Flomax Flanges

Force lbs (N) Moment ft*lbs (N*m)

FL FC FA ML MC MT

1.5”

405

(1800)

405

(1800)

303

(1350)

100

(135)

149

(203)

129

(176)

2”

540

(2400)

540

(2400)

405

(1800)

177

(240)

266

(360)

230

(312)

Loading...

Loading...