FLOMAX 8 BZ AL (en) Page 5 of 24

MOTOR MOUNTING

Check rotation of the driver to be sure it coincides with the

required rotation of the pump. When viewed from the driver

end the rotation of the pump is CLOCKWISE.

A Pumpak shaft sleeve is machined to precisely t the shaft

of your driver. No provision is made for drive key and none is

required.

Loosen the drive clamp fasteners but do not remove. NOTE:

If the driver shaft is keyed, remove the key before attempting

to install the Pumpak. Slide the Pumpak assembly onto the

driver shaft, aligning the Cap Screw holes in the adaptor with

the tapped holes in the driver mounting face until the adap-

tor contacts the mounting face.

Install fasteners and tighten to secure Pumpak assembly to

the driver. First center then tighten the drive clamp assembly

to lock the shaft sleeve onto the driver shaft.

After all fasteners are tight including the drive clamp assem-

bly, remove the Assembly shim from the suction connection.

The shim was in place to establish clearance between the

face of the impeller and pump housing. Rotate the driver

slowly by hand to make certain that there is no rubbing.

Mounting Pumpak

Loosen impeller clamp nuts.

Do not use drive shaft key. Remove key if installed on drive

shaft.

Slide PUMPAK assembly onto the drive shaft. WARNING! If

PUMPAK does not slide freely STOP DO NOT HAMMER or

force PUMPAK. Be sure impeller clamp is loose. PUMPAK as-

semblies should slide on with hand pressure. Check for and

remove any burrs from drive shaft or bore of sleeve. Align

holes in adapter with holes in driver mounting face and slide

PUMPAK until adaptor contacts mounting face.

Attach Cap Screws and lockwashers and tighten to secure

PUMPAK assembly to driver. Tighten impeller clamp nuts to

lock impeller onto drive shaft.

TO ADJUST IMPELLER CLEARANCE:

NOTE: A shipping spacer was inserted at the factory for the

purpose of establishing the proper clearance between the

face of impeller and the wear plate.

1. Remove strip stock spacer only after tightening the

impeller.

2. Clearance between the impeller and wear plate is now

set to approximately 0.020”.

3. Turn over slowly to make certain pump rotates freely.

4. Loosen impeller clamp to adjust clearance between im-

peller and wear plate using a feeler.

5. Gauge in place of spacer. After clearance has been estab-

lished, tighten impeller clamp to lock impeller to shaft.

Torque Specications

Size Stainless Steel (ft-lbs) Steel GR5 (ft-lbs)

5/16” - 18” 10 - 14 14 - 20

3/8” - 16” 20 - 2 6 26 - 32

1/2” - 1 3” 34 - 42 70 - 80

1/2” - 20” 40 - 4 8 N/A

5/8” - 11” 75 - 85 N/A

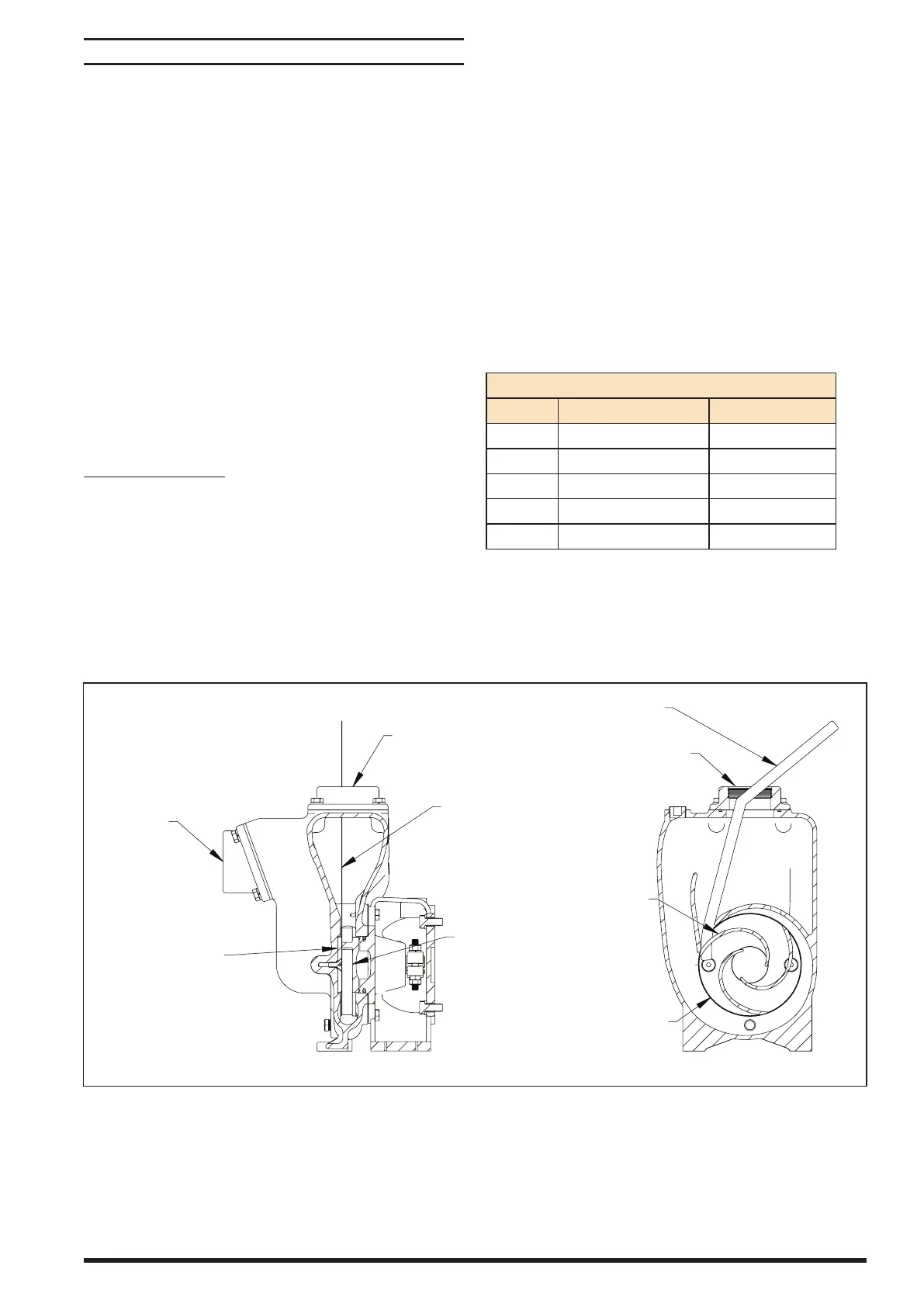

(24 GAUGE)

DISCHARGE

IMPELLER

WEAR PLATE

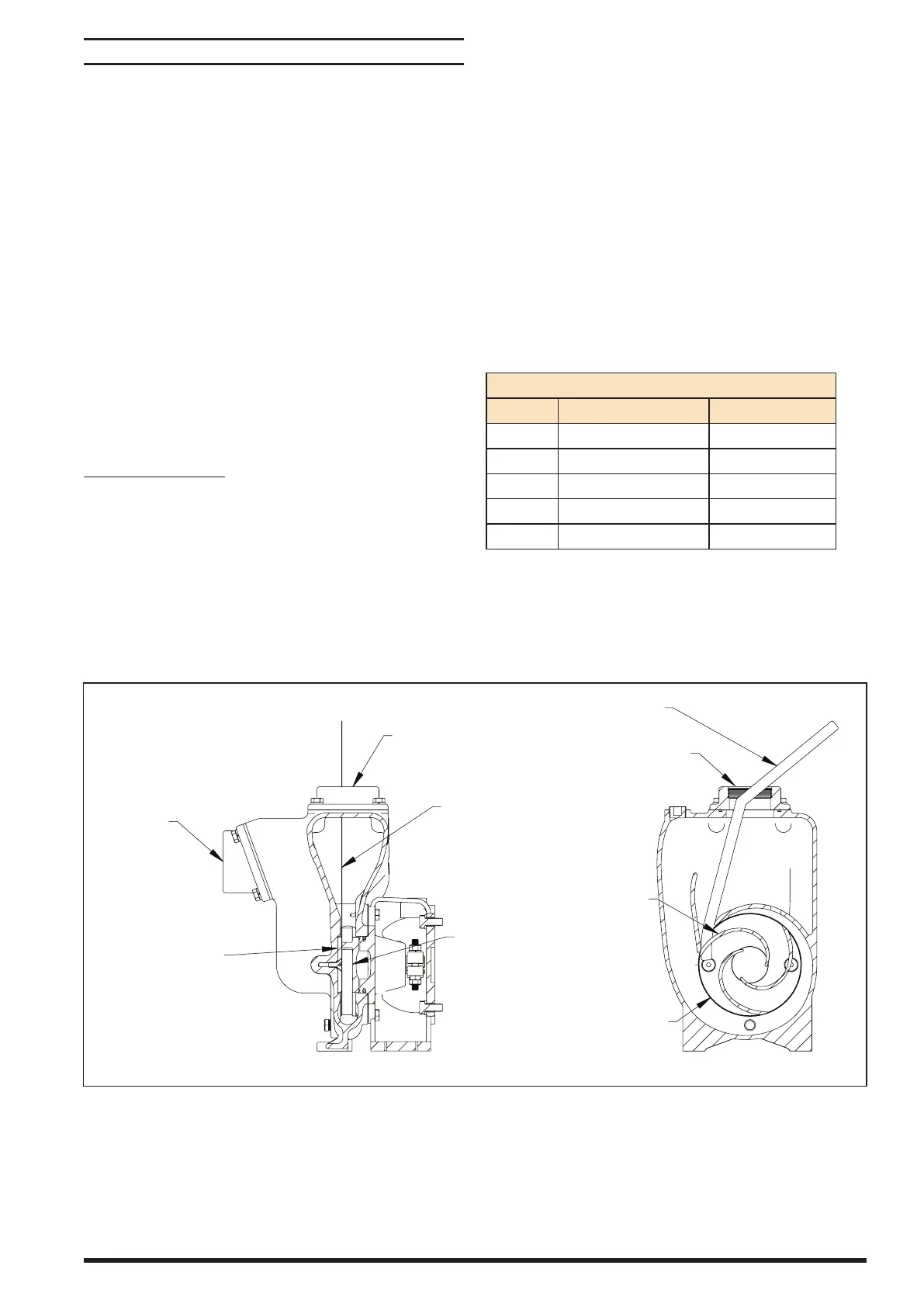

DISCHARGE

WEAR PLATE

IMPELLER

SHIM

(24 GAUGE)

Figure 2

Loading...

Loading...