Page 6 of 24 FLOMAX 8 BZ AL (en)

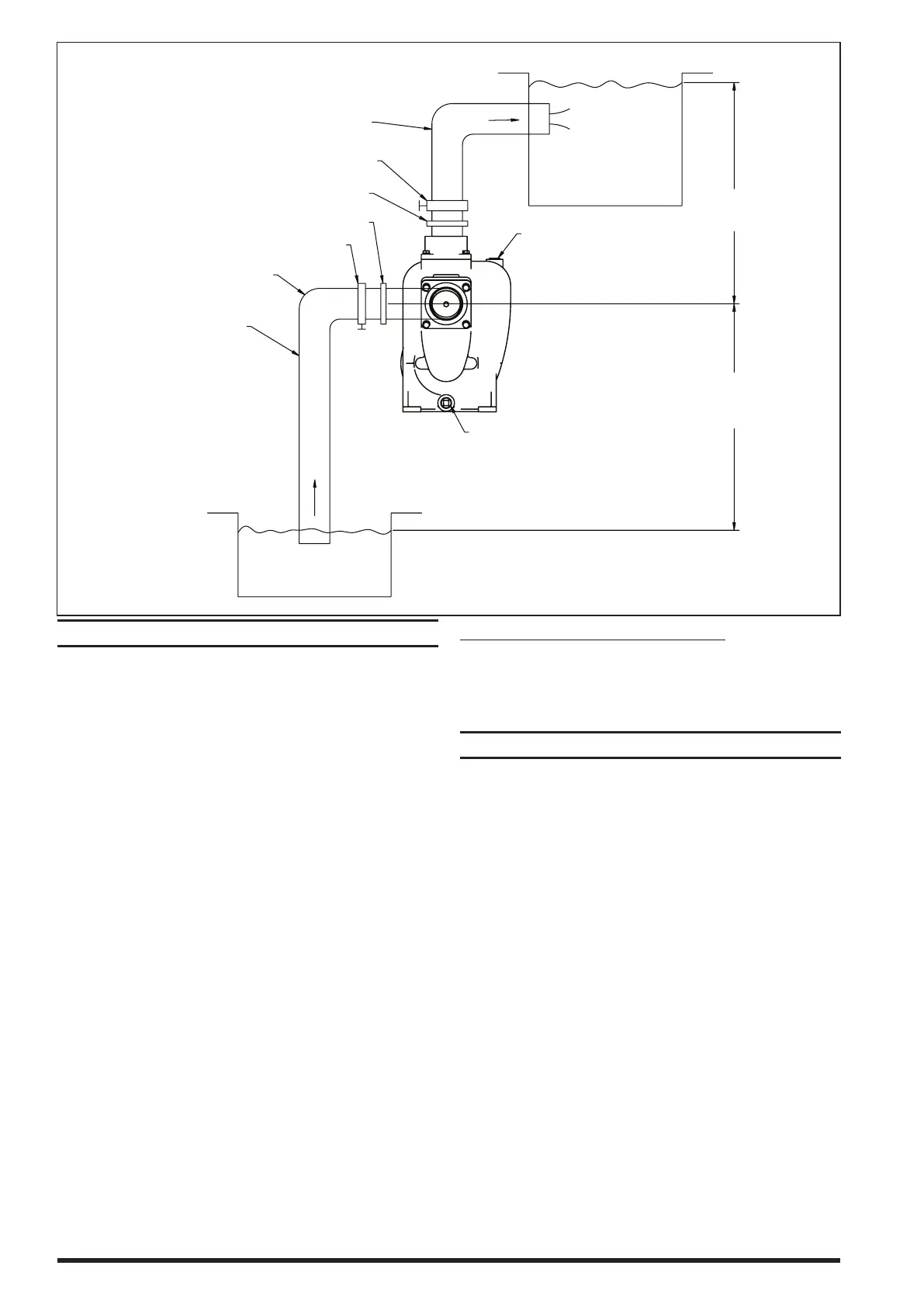

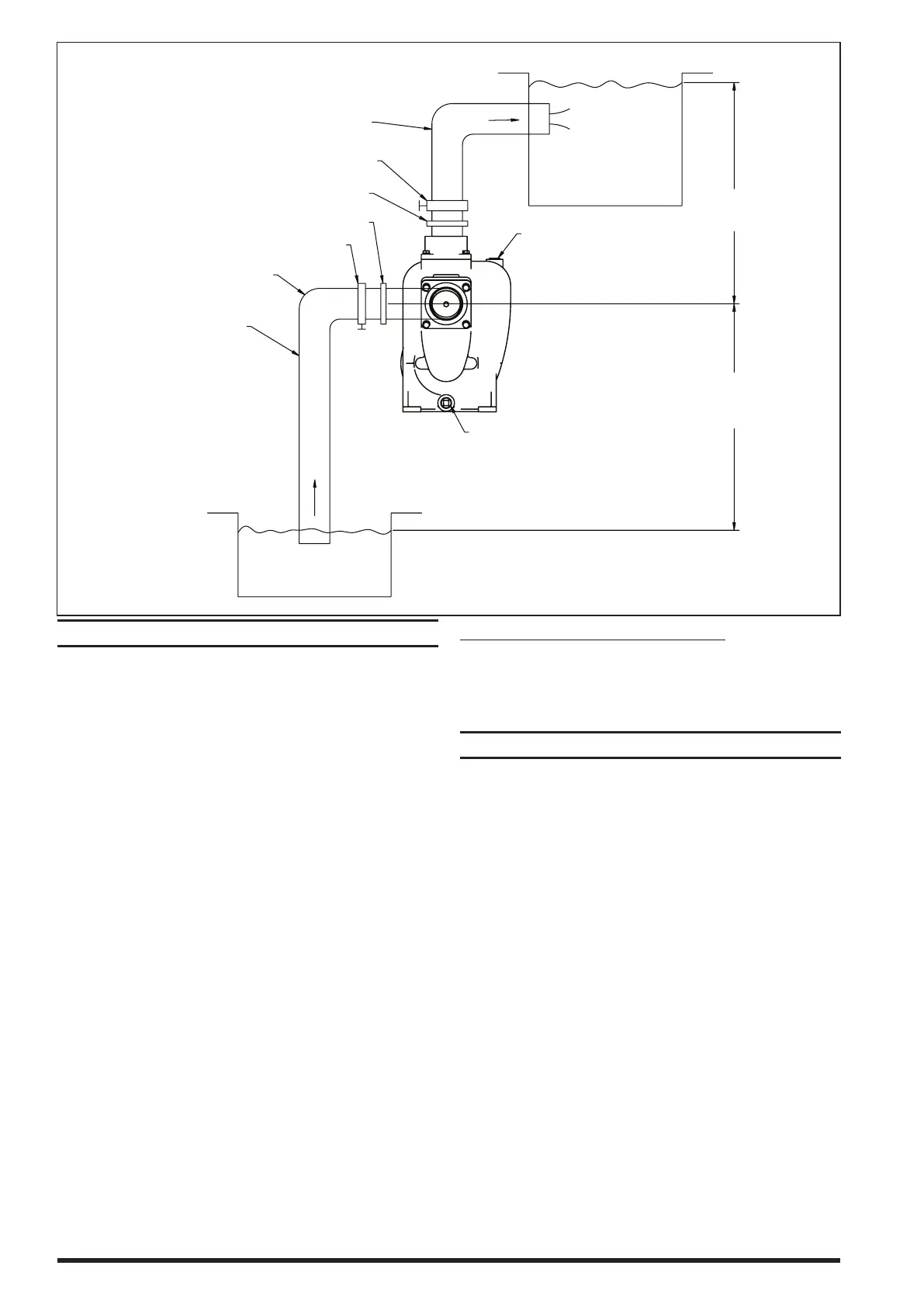

WORKING OF SELF PRIMING PUMP

Hd

DISCHARGE HEA

Hs

SUCTION HEAD

(NPSHr)

FILL PLUG

DRAIN PLUG

OVER HEAD

WATER TANK

SUCTION VALVE

UNION FLANGE

UNION FLANGE

DISCHARGE VALVE

DISCHARGE PIPE (2”)

SUCTION PIPE (2”)

SHARP BENDS NEAR INLET

Figure 3

OPERATING INSTRUCTIONS

The FLOMAX pump is a self-priming centrifugal pump and

only requires priming prior to its initial start. The pump will

retain sucient liquid for self priming thereafter.

Provision for a priming plug can be made by using a close

nipple and tee on the discharge opening.

A pipe plug installed in the top opening of the tee is easily

removed when necessary to prime pump. Prime pump by ll-

ing pump housing with liquid

If pump fails to prime or stops pumping, check for the follow-

ing possible causes:

1. No liquid in the pump housing.

2. Air leak in the suction line due to loose connections or

pin holes in the hose.

3. Collapsed suction line or clogged strainer.

4. Seal worn and leaking air.

5. Worn impeller - too much clearance between impeller

and wear plate.

6. Pump not running fast enough.

7. Suction lift is too high.

8. Trying to prime against too high a discharge head

Inspect the Pumpak as soon as it is received to make certain

that no parts are missing or have been broken in shipment.

Damage should be reported immediately to the shipping

company. CAUTION: Do not disturb the assembly shim in

the opening of the pump housing until after the Pumpak has

been completely assembled to the driver.

The Pumpak utilizes a single self-adjusting type mechanical

seal that is lubricated and cooled by the liquid in the pump.

NOTE: The Pump Must Never Be Operated Without Liquid

In The Housing.

WORKING OF SELF PRIMING PUMP:

A centrifugal pump operates through the transfer of rotation-

al energy from one or more driven rotors, called impellers.

The action of the impeller increases the fluid’s velocity and

pressure and directs it towards the pump outlet.

WEAR AND INSPECTION POINTS

Shaft: Inspect threads, keyways and shoulders. Replace if

damaged.

Ball bearings (Pedestal and hydraulic models): Replace if

worn, loose, or rough and noisy when rotated. If dirty, clean

with solvent, dry and coat with a good lubricant. New bear-

ings should not be unwrapped until ready for use.

Impellers: Replace if excessively worn or corroded. The im-

peller should have been statically and dynamically balanced

at the factory, and static and dynamic balance must be main-

tained for proper operation of your equipment.

Mechanical seals: Should be inspected for, lack of lubrica-

tion, misalignment, overheating, abrasive materials damage,

and corrosion.

Alignment: Proper alignment between pump shaft and

motor shaft is key to the performance of shaft seals and

bearings. Improper alignment can lead to premature pump

failure.

Pedestal Style: Inline shaft to shaft spacing is dependent

upon the coupling being used. Check the alignment carefully

between the pump and the drive.

Loading...

Loading...