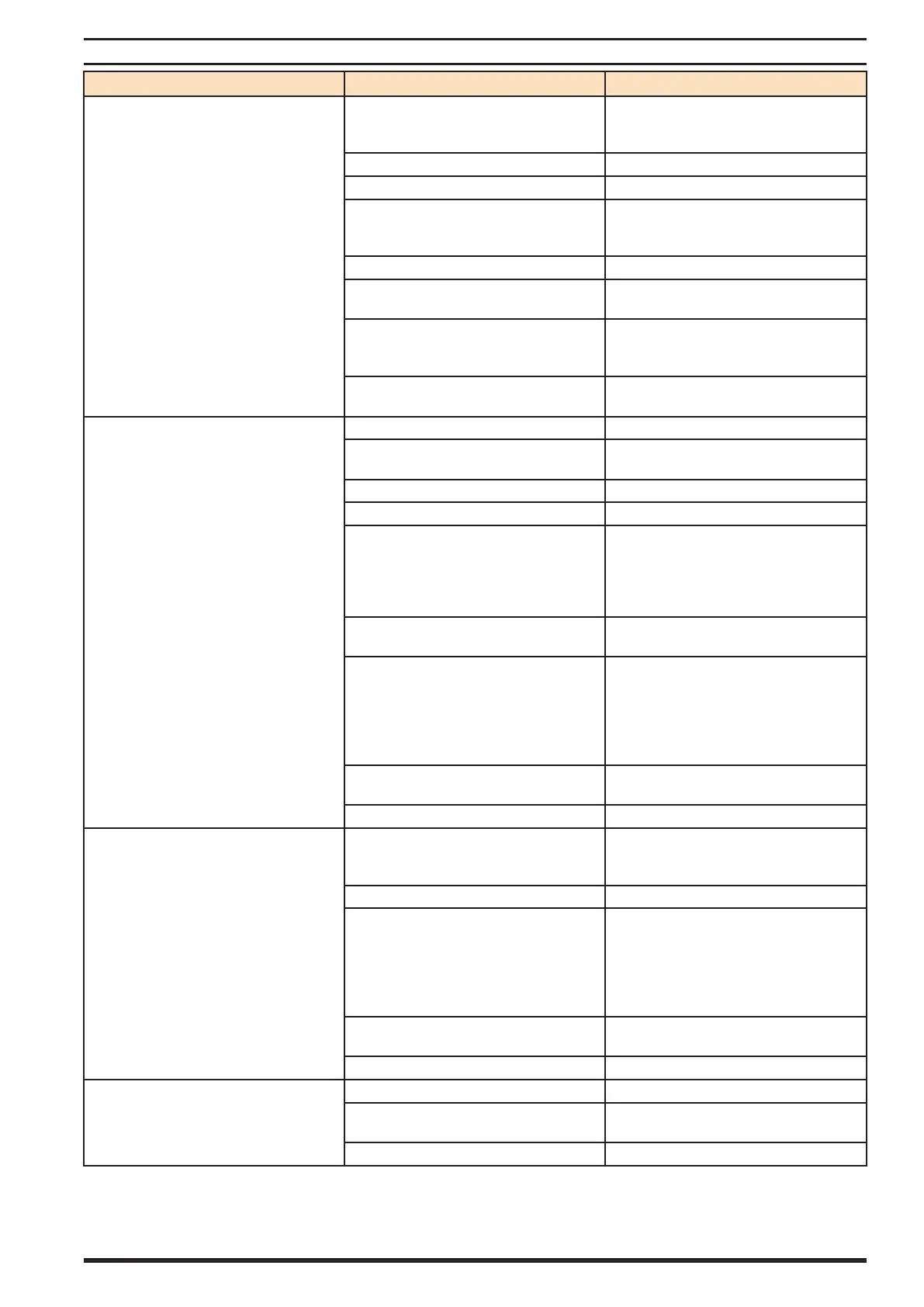

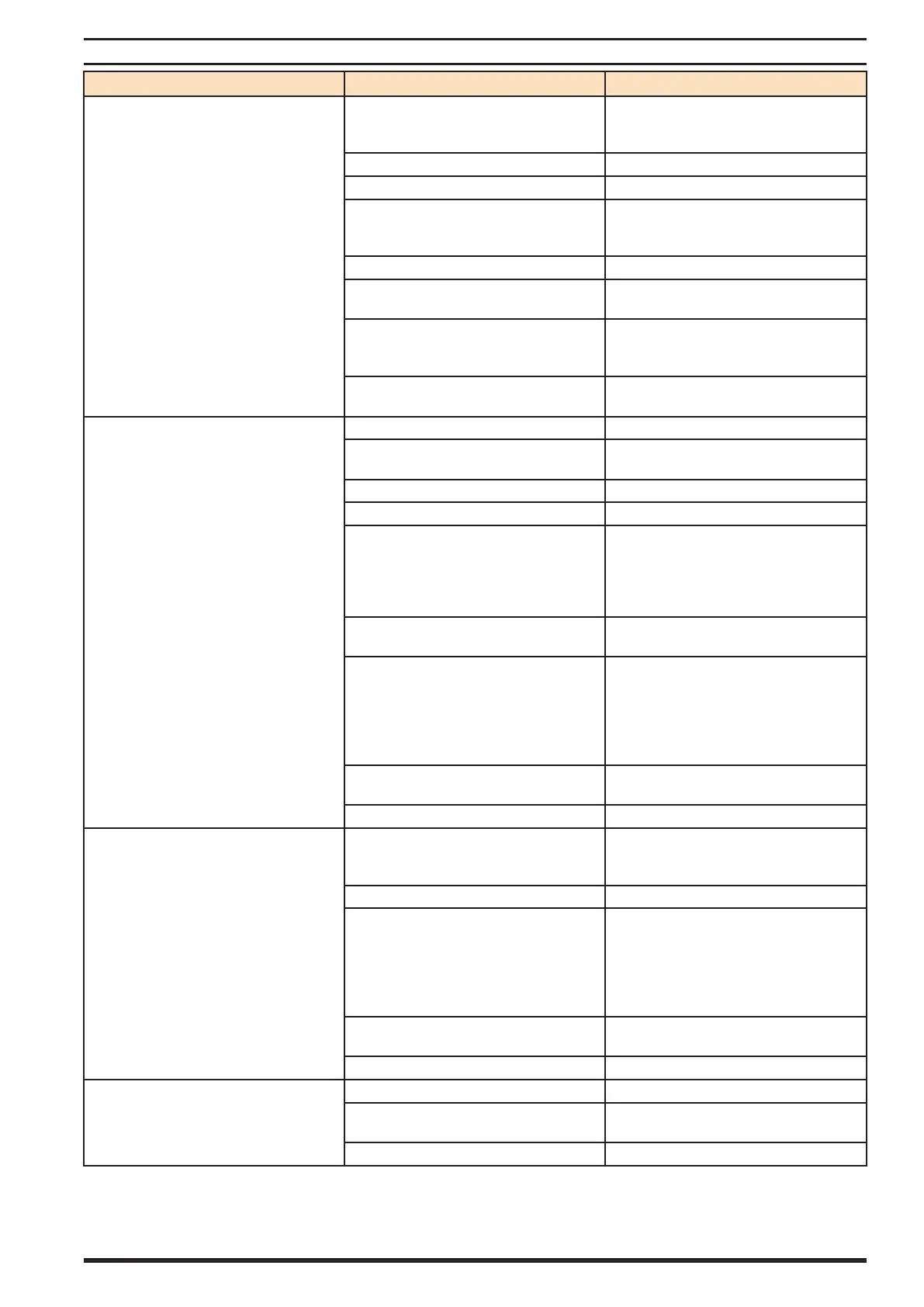

FLOMAX 8 BZ AL (en) Page 23 of 24

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE REMEDY

No liquid delivered.

1. Pump not primed.

1. Reprime pump, check that pump and

there are no obstructions in the suc-

tion line.

2. Discharge valve closed 2. Check discharge valve.

3. Suction line clogged. 3. Remove obstructions.

4. Wrong direction of rotation.

4. Change rotation to concur with direc-

tion indicated on bearing housing or

pump casing.

5. Total head is too high 5. Re-evaluate head conditions.

6. Driver is not operating at rated speed.

6. Check electric motor voltage;check

engine rpm

7. Pump is vapor bound

7. Provide additional pressure on liq-

uid being pumped by elevating liquid

source.

8. Foot valve or suction pipe opening

not submerged enough

8. Consult factory for proper depth. Use

baer to eliminate vortices.

Pump not producing rated ow or head.

1. Air leak through gasket. 1. Replace gasket.

2. Air leak through stung box.

2. Replace or adjust packing/mechanical

seal.

3. Impeller partly clogged. 3. Back ush pump to clean impeller.

4. Worn suction side plate or wear rings. 4. Replace defective parts as required.

5. Pump is not properly primed.

5. Reprime pump, check that pump and

there are no obstructions in the suc-

tion line. Check NPSHa to ensure that

there is enough liquid for pump oper-

ation.

6. Driver is not operating at rated speed.

6. Check electric motor voltage; check

engine rpm

7. Pump is vapor bound

7. Provide additional pressure on liquid

being pumped by elevating liquid

source. or consider installing an air

release valve in the discharge line

to remove the air to allow the pump

to become dynamic.

8. Insucient suction head.

8. Ensure that suction line shuto valve

is fully open and line is unobstructed.

9. Worn or broken impeller. 9. Inspect and replace if necessary.

Pump starts then stops pumping.

1. Excessive air in liquid.

1. Clean and tighten all suction connec-

tions; relocate suction inlet in liquid

source.

2. Defective packing or seal. 2. Replace packing or seal.

3. Pump is vapor bound.

3. Provide additional pressure on liquid

being pumped by elevating liquid

source. or consider installing an air

release valve in the discharge line

to remove the air to allow the pump

to become dynamic.

4. Air or vapor pockets in suction line.

4. Rearrange piping to eliminate air

pockets.

5. Air leak in suction line. 5. Repair leak.

Bearings run hot.

1. Improper alignment. 1. Re-align pump and drive.

2. Improper lubrication.

2. Check lubricate for suitability and

level.

3. Lube cooling. 3. Check cooling system

Loading...

Loading...