FLOMAX 8 BZ AL (en) Page 7 of 24

SEAL REPLACEMENT INSTRUCTIONS

DISASSEMBLE THE PUMP:

Drain the system of liquid, break suction and discharge pipe

unions, and, if necessary, remove all piping from the suction

and discharge openings. Remove the fasteners holding the

pump adaptor to the driver, loosen the drive clamp assembly,

and remove the PUMPAK.

To disassemble, remove the washers and hexnuts holding the

motor adaptor to the housing. Remove the housing. The im-

peller, drive sleeve, seal bellows, and the spring assembly will

now slide forward Free of the pump adapter.

The seal seat and seat cup will remain in the pump adaptor.

If not damaged or worn, do not remove. If necessary, remove

from the adaptor counter bore with a piece of wood or a

screwdriver handle inserted through the adaptor from the

drive end. A sharp tap or two is usually sucient to knock out

the seal seat. Use caution in removing the seal seat so as not

to crack a ceramic seat.

REMOVE IMPELLER

Remove seal bellows and spring assembly. On some models,

spring keeper can also be removed now before removing im-

peller.

NOTE: The seal bellows will be bonded to the shaft sleeve

and will require some patience and caution in removal in or-

der not to damage the seal bellow and cage.

MP Pumps rebuild kits include a new drive sleeve to avoid the

possibility of damaging the drive sleeve. See back of manual

for list of seal kits and corresponding rebuild kits. Impellers

are also available if wear or damage is present.

Remove locknut from shaft; unscrew the impeller from the

shaft sleeve counter-clockwise from the impeller end.

INSPECTION:

Check all parts for wear. For ease of reassembly shaft sleeve

should have all nicks and burrs removed. Clean with light cro-

cus cloth. Replace damaged parts with new parts.

Inspect the seal seat and washer, seat cup, and seal bellows

for grooves, cuts, scumarks, or other deterioration. If any of

the parts are damaged, a complete new assembly should be

installed.

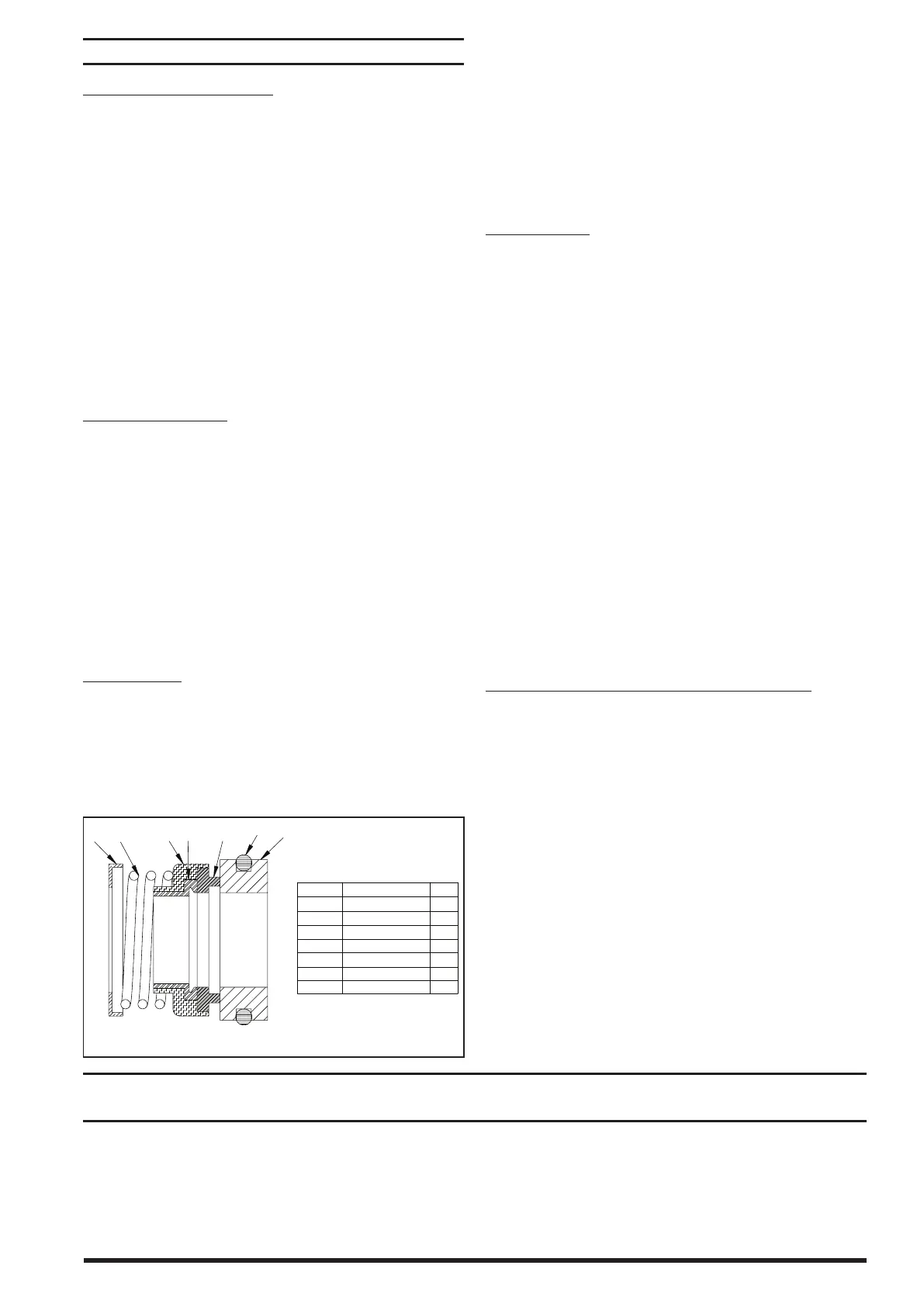

6

54

3

1

ITEM NO. DESCRIPTIONQTY.

Mating Ring

2

3

4

5

6

7

1

1

1

1

1

1

1

1

O-ring

Primary Ring

Elastomer Bellows

Drive Band

Spring

Spring Holder

inspect the lapped sealing face of carbon washer (Part 3) for

wear which would necessitate replacement.

Inspect lapped sealing face of oating seat (Part 4) in adapter

housing counterbore for scung or cracks. If necessary to re-

place, press out old seat and ring, and proceed as outlined in

paragraph on MOUNTING ADAPTER.

If spring and/or bellows (Part 1 and 2) are damaged and re-

quire replacement, lubricate the impeller sleeve with a clean

light oil and slide parts o sleeve.

REASSEMBLY:

All dirt and foreign matter should be removed. Recommend

only using new seals and elastomers when reassembling a

pump.

Lubricate seal seat cup with liquid soap (P-80 emulsifier) or

clean grease and press seal seat into adaptor counter bore,

seating it firmly and squarely. Use caution so as not to mar

the lapped face of the seal seat.

Assemble shaft sleeve; seal spring keeper, impeller and im-

peller nut. Before installing seal bellows and spring assembly,

lubricate the shaft sleeve and rubber bellows with liquid soap

(P-80 emulsier) or clean grease and press bellows and spring

assembly onto the shaft sleeve. The spring should engage the

spring keeper at the impeller end of the shaft sleeve.

To be properly positioned the washer must be rmly against

the rubber bellows member and the driving lugs of the wash-

er properly engaged. The raised shoulder on the seal wash-

er should be facing away from the impeller to contact the

lapped surface of the seal seat in the adaptor.

Slide impeller and seal assembly into the adaptor. Install drive

clamp assembly on the shaft sleeve but do not tighten.

Make sure the shim is installed between the impeller and the

wear plate. Do not remove the shim material before the drive

sleeve clamp has been tightened to the motor drive shaft.

INSTRUCTIONS FOR SET SCREW TYPE SEAL:

Do not remove the seal retaining clips. Slide the seal into

place on the shaft. The end of the shaft will be recessed

approximately 0.080” ± 0.020” from the end of the seal. The

proper seal working height is achieved when the seal faces

are set ush with the seal clips in place.

With the seal clips still in place tighten the seal fasteners with

a ball end allen wrench. It is important that the allen wrench

not rest upon the seal housing during tightening as this may

aect the position of the seal on the shaft. After the seal fas-

teners have been tightened the seal clips should be removed

and saved.

Do not use the seal shim with setscrew type seal.

For bellows seal install the seal spacer on the backside of the

impeller. Use a light grease or similar tacky material. Thread

impeller onto shaft. Install jam nut. Place O-ring onto seal

plate. Install impeller/bearing housing assembly into pump

housing. Install lock washers and hex nuts. Rotate the shaft

several times to check for rubbing or binding.

BEARING REPLACEMENT INSTRUCTIONS

(PEDESTAL MODELS)

The pump utilizes a single self-adjusting type mechanical seal

that is lubricated and cooled by the liquid in the pump.

THE PUMP MUST NEVER BE OPERATED WITHOUT LIQUID

IN THE HOUSING.

Check rotation of the driver to be sure it coincides with the

required rotation of the pump. When viewed from the driver

end the rotation of the pump is CLOCKWISE.

The pump’s grease lubricated bearings are sealed. They have

been pre-lubricated at the factory and require no further

lubrication or maintenance for the life of the bearing.

Loading...

Loading...