FLOMAX 8 BZ AL (en) Page 9 of 24

Lubricate the inside of the washer and bellows assembly (Part

2 and 3) with a clean light oil and slide it onto the impeller

drive sleeve only until it clears the chamfer.

Slide the seal bellows and washer assembly onto the impeller

drive sleeve. Push the seal down over the drive sleeve with

even pressure. Pull the seal head back up to the position

where there is no spring load. This insures proper assembly

on the drive sleeve.

Before sliding the impeller onto the drive shaft, wipe the

lapped sealing faces of the oating seat (Part 4) in the adapt-

er counterbore and the carbon washer (Part 3) on the bellows

assembly perfectly clean. Then lubricate both faces with a

clean light oil.

NOTE: The assembly of impeller and seal to the drive shaft

should take place as soon as the bellows assembly is slipped

on the impeller sleeve so as to avoid bonding of the bellows

to the sleeve at improper working height.

CAUTION: Foreign matter between sealing faces will cause

leakage and shorten the life of the seal.

MOUNTING GREASE LUBRICATED SEAL ASSEMBLY

Apply P80 to seal seat bore in seal housing and around O-ring

on carbon seal seat. Then press seal seat, by hand, into seal

seat bore making sure marked side of seal seat is down. Clean

and inspect for cracks, chips and deformities.

Dot

O Ring

Figure 5

Place gasket over studs and O-ring into groove then install

seal housing over studs with seal facing up with ¼ NPT holes

at 2 o’clock and 7 o’clock position. Inspect and wipe clean if

needed. Apply P80 to impeller drive sleeve and to interior

of seal bellows, and push onto drive sleeve with seal pusher

with silicon carbide seal facing downward towards impeller.

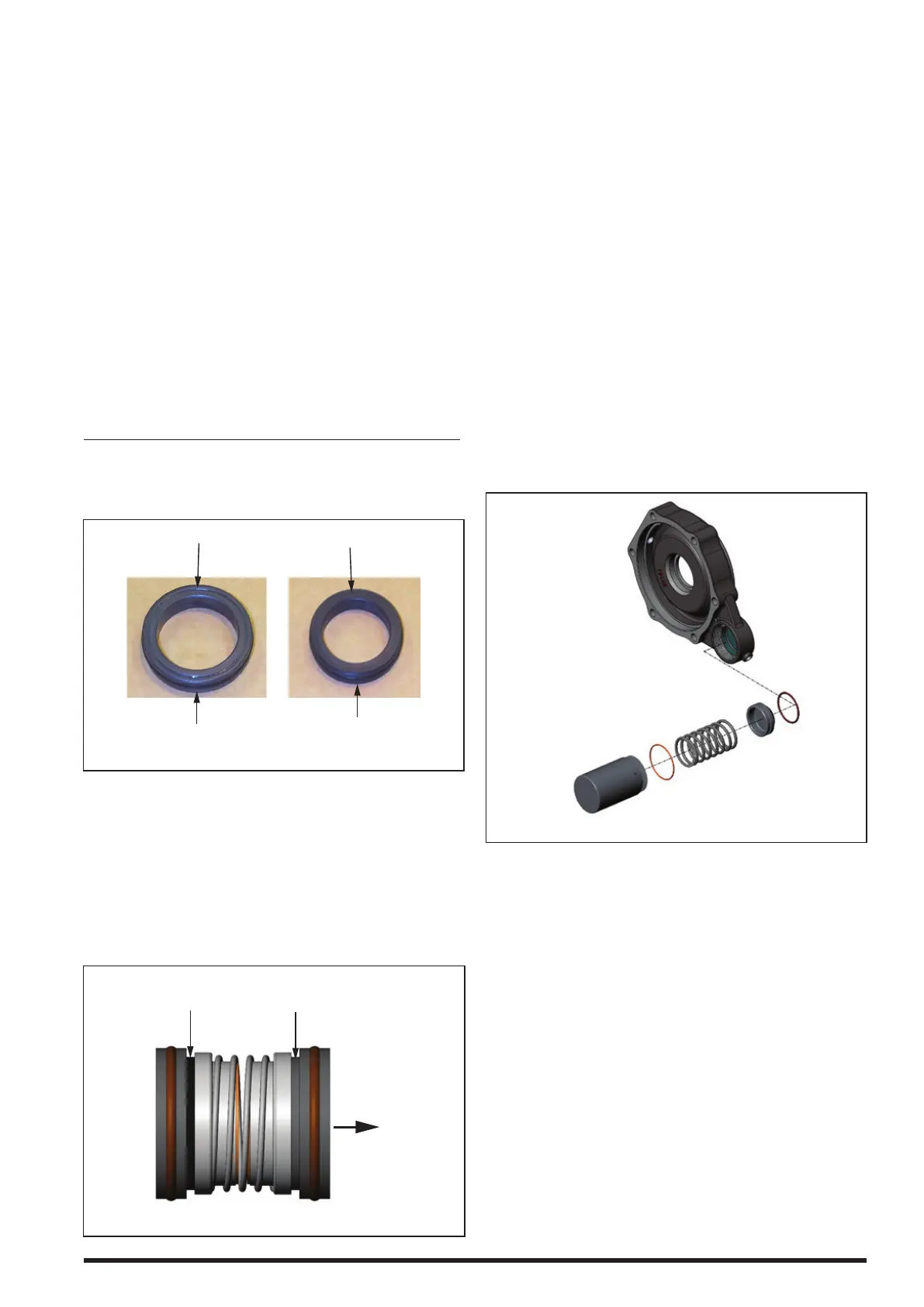

The silicon carbide face is a matte light gray. The carbon face

is a very dark gray/black. See the picture below. Some seals

have the same primary seal face and therefor the direction

does not matter.

Seal Face (black)

Seal Face (gray)

To

Impeller

Figure 6

Install seal spring over drive sleeve onto backside of silicon

carbide seal. Apply P80 to interior seal bellows of carbon seal

and push over drive sleeve with seal pusher carbon face up.

Inspect and wipe clean, if necessary. Install gasket over studs

onto seal housing. Apply P80 to seal seat bore of adapter and

around O-ring on seal seat. Push seal seat, by hand, into seal

bore – clean and inspect.

Install O-ring into adaptor groove. Apply P80 to O-ring. Place

adapter onto seal housing gasket, handle hole up, and attach

using 6 hex nuts and lock washers. Assemble clamp assembly

over drive sleeve. Leave loose.

Apply Gasoila onto threads of grease fitting and install to

lower pipe tting hole at 10 o’clock position in seal housing

and tighten by hand. NOTE: Do not get sealant into grease

fitting. Apply Gasoila to 1/8” NPT plug and install into pipe

tting at 5 o’clock position. Apply Gasoila to pressure release

valve threads and install into upper pipe tting hole at the 10

o’clock position.

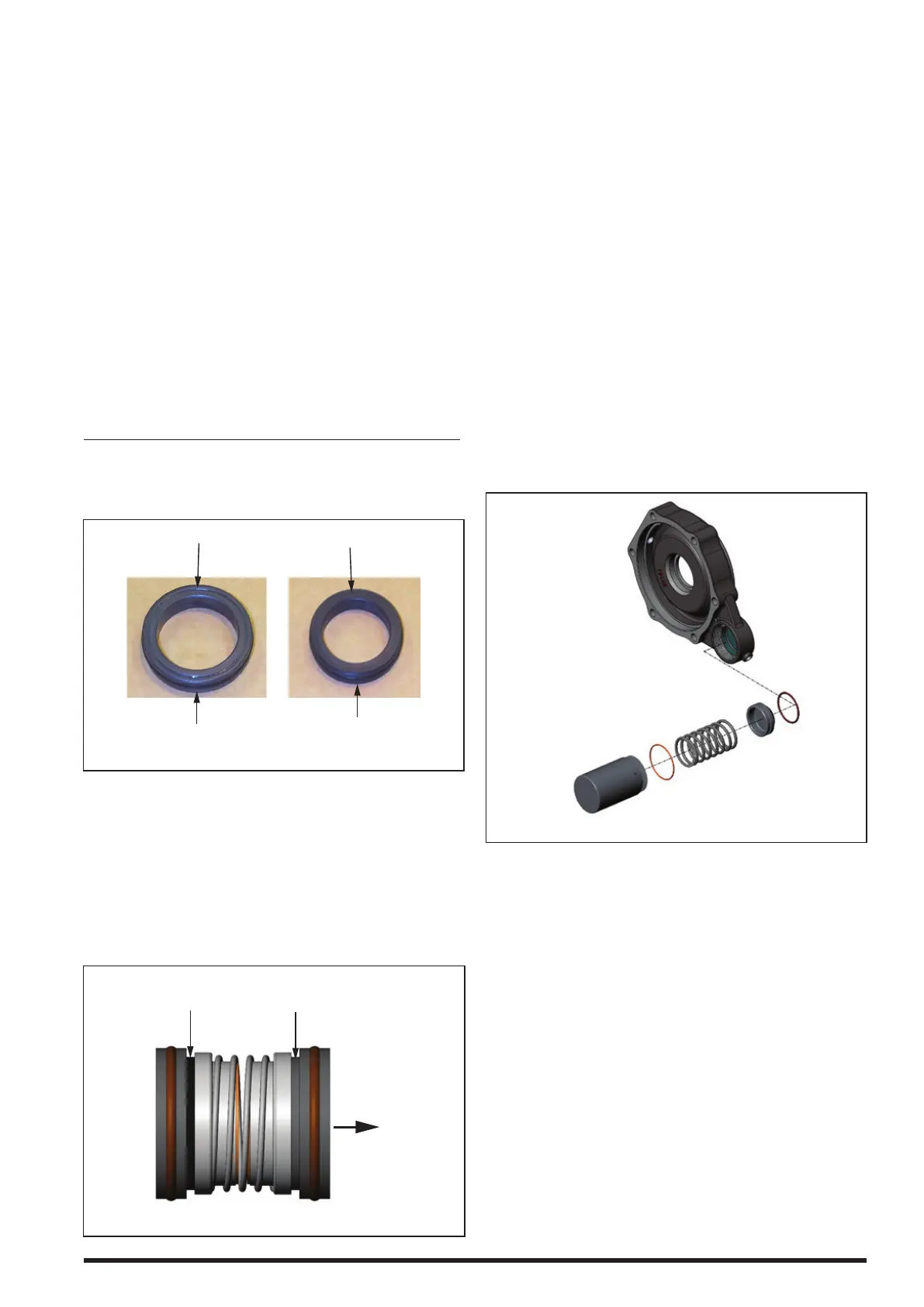

Fill seal cavity with grease until it comes out of the reservoir

hole. Assembly grease reservoir into adaptor as shown below.

Place smaller O-ring over the piston. Place the large O-ring

over the reservoir cover. Install the piston into the adaptor

hole. Place the spring within the piston. Thread the cover

into the adaptor.

Figure 7

Continue filling seal cavity until high-pressure grease reser-

voir is full. NOTE: When grease reservoir is full it will spit out

of the pressure release valve.

Loading...

Loading...