R-Series Models RP and RH Temposonics

®

Linear-Position Sensors - SSI Output

Product Data Sheet, Part No.: 550989 Revision E (EN) 05/2014 MTS Sensors10

R-Series Model RH Rod-Style Sensor

Mounting and Cylinder Installation

Model RH rod-style sensor mounting

MODEL RH SENSOR MOUNTING

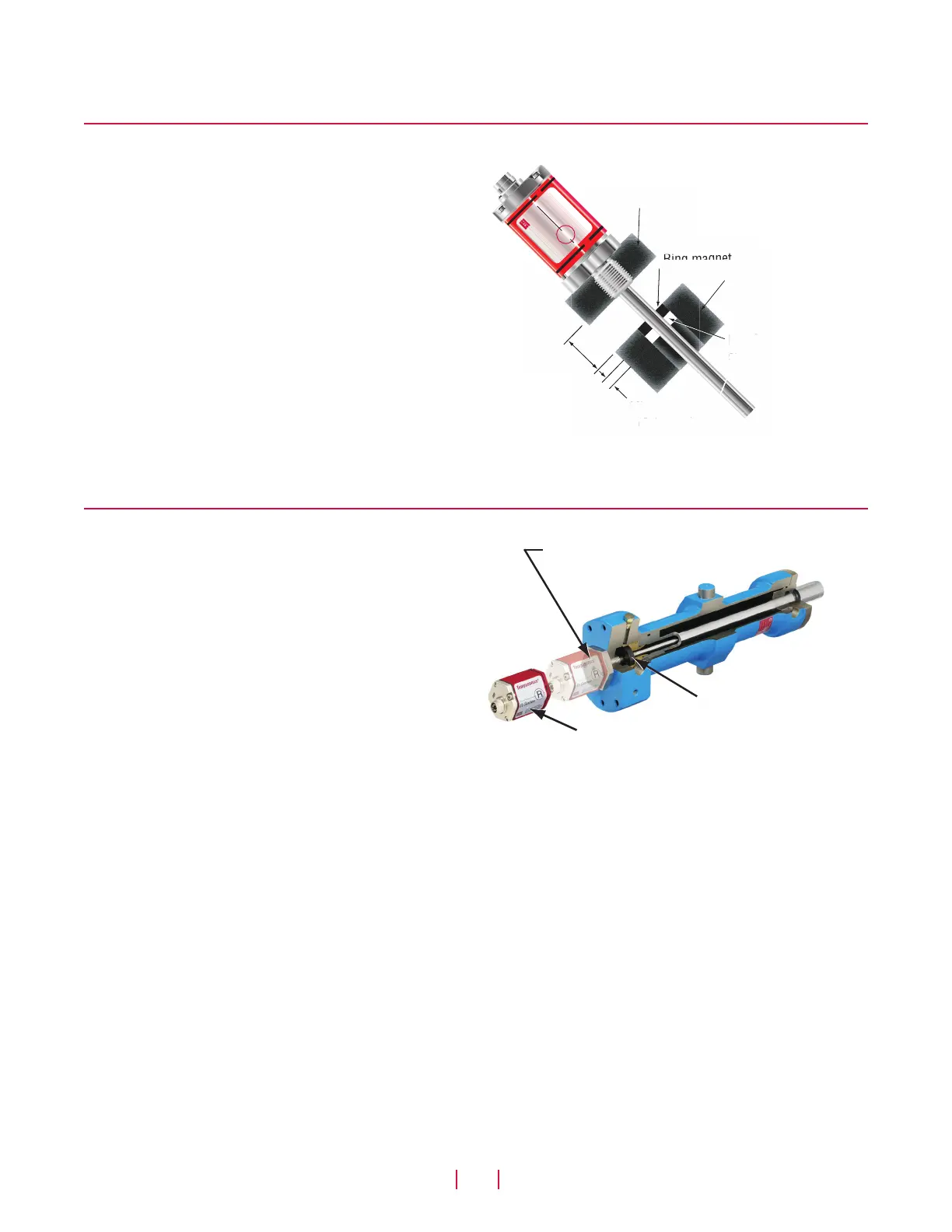

The position magnet requires minimum distances away from ferrous

metals to allow proper sensor output. The minimum distance from

the front of the magnet to the cylinder end cap is 15 mm (0.6 in.).

The minimum distance from the back of the magnet to the piston

head is 3.2 mm (0.125 in.). However, a minimum distance of at

least 5 mm (0.197 in.) is preferred for added performance margin.

The non-ferrous spacer (part no. 400633), provides this minimum

distance when used along with the standard ring magnet (part no.:

201542-2) as shown in Figure 13.

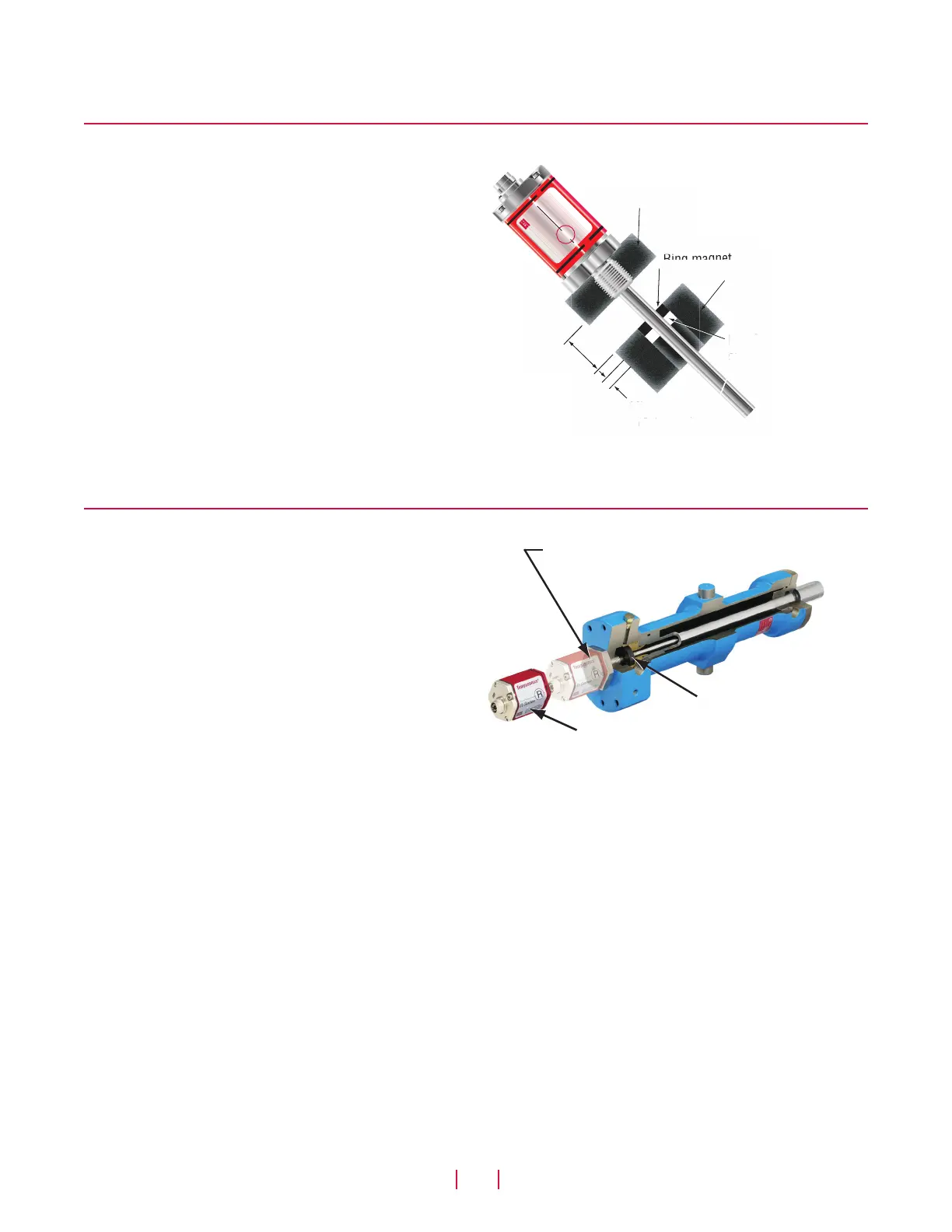

Cylinder installation

The sensor’s rod housing and flange can remain

permanently installed in the cylinder

Ring magnet

The sensor cartridge, consisting of the electronics housing

and sensing element, is easy to replace by removing

(2) M4 thread 2.5 mm hex socket head screws

Figure 14. Fluid cylinder installation

Figure 13.

Non ferrous

spacer

> 15 mm

(0.6 in.)

Min. 3.2 mm

(0.125 in.)

Ring magnet

Cylinder end cap

Piston head

Temposonics

®

R-Series

R

®

Model RH rod-style mounting

When used for direct-stroke measurement in fluid cylinders, the

sensor's high pressure, stainless steel rod installs into a bore in

the piston head/rod assembly as shown in Figure 14. This method

guarantees a long-life and trouble-free operation.

The sensor cartridge can be removed from the flange and rod hous-

ing while still installed in the cylinder. This procedure allows quick

and easy sensor cartridge replacement, without the loss of hydraulic

pressure.

Loading...

Loading...