Installing Lambda sensor

Note: When the sensor was subjected to shock or

impact load, it is deemed to be defective and

may not be used.

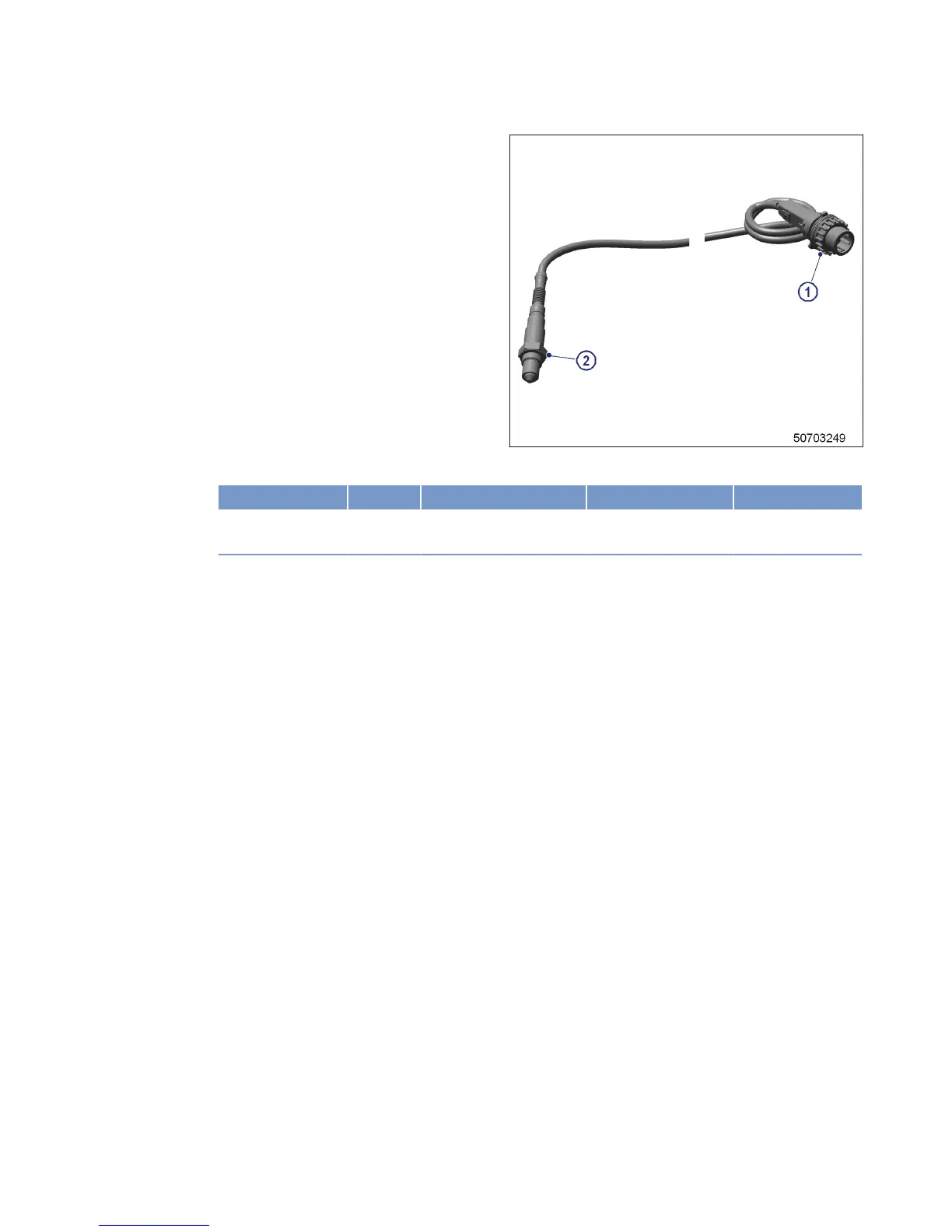

1. Remove protective cap on thread only just

before installation.

Note: Do not wipe off the thread lubricant applied

by the manufacturer.

2. Coat sensor thread with specified assembly

compound as required.

3. Screw in sensor by hand.

4. Tighten nut (2) to specified torque using a torque wrench.

Name Size Type Lubricant Value/Standard

Nut M18 x 1.5 Tightening torque (Assembly compound

(Molykote P 37))

40 Nm to 60 Nm

5. Fit male connector (1) and latch it.

6. Reset Lambda sensor calibration with DiaSys® (→ Dialog system DiaSys® E531920/..). If no DiaSys® is

available, contact Service.

MS150094/02E 2015-05 | Task Description | 141

TIM-ID: 0000025194 - 014

Loading...

Loading...